SIW-based single-ridge ultra-wideband H-plane horn antenna

A horn antenna and ultra-wideband technology, which is applied to antennas, waveguide horns, and devices that make antennas work in different bands at the same time, can solve the problem of reducing the equivalent characteristic impedance of SIW, increasing the working bandwidth of the horn antenna, and adding a complex structure of the horn antenna. and other problems, to achieve the effect of reducing equivalent characteristic impedance, simple ridge structure, and improved antenna performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

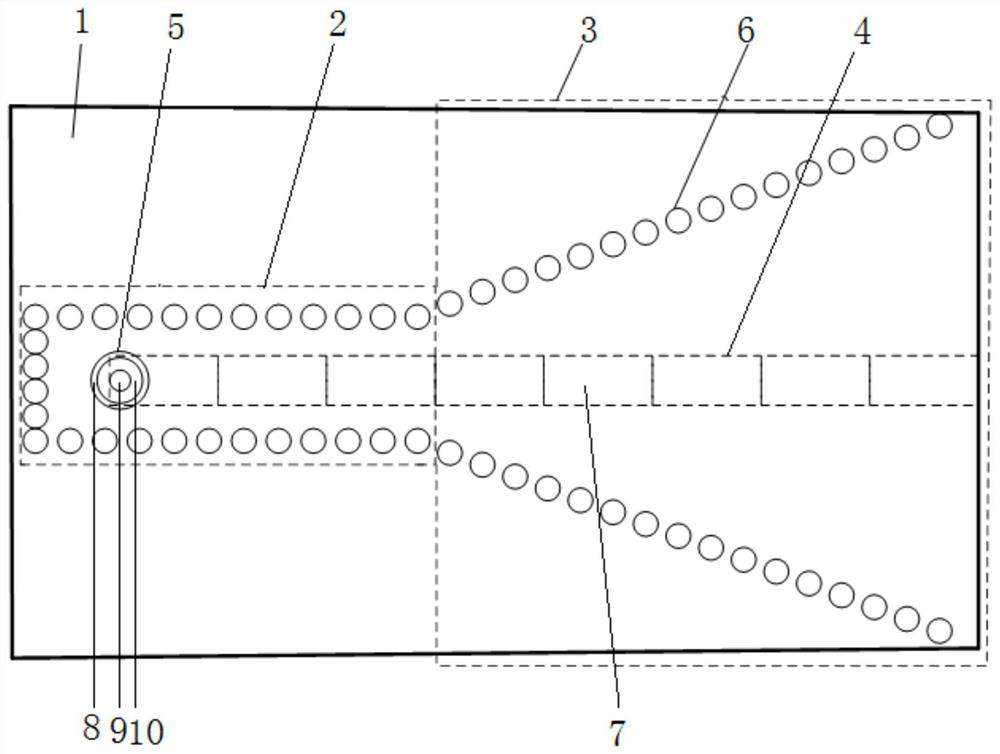

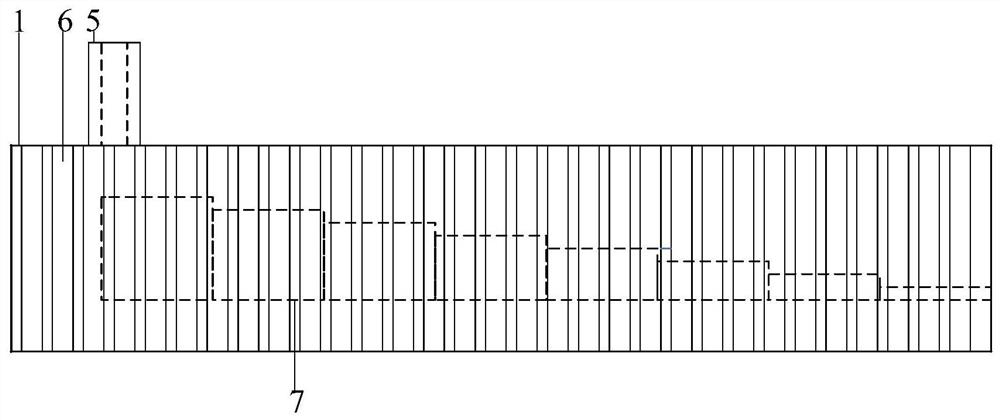

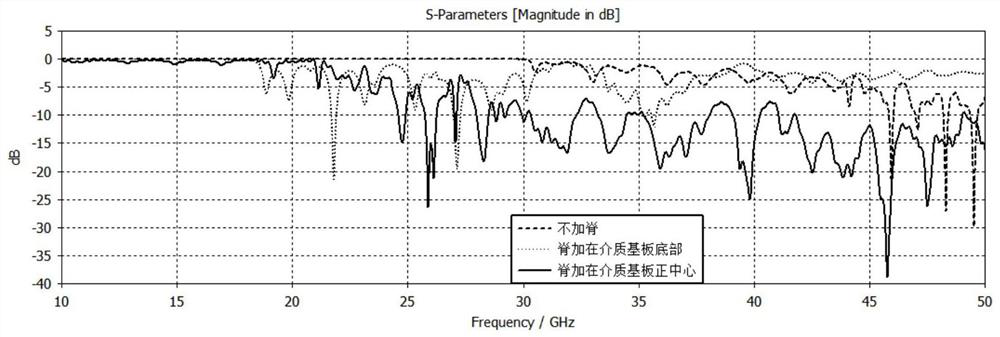

[0024] The present invention proposes a single-ridge ultra-wideband H-plane horn antenna based on SIW, such as figure 1 As shown, it includes a dielectric substrate 1, an SIW structure 2, an H-plane horn antenna 3, a ridge structure 4 and a feeding coaxial line 5, wherein the ridge structure is arranged on the central axis of the dielectric substrate, and the SIW structure and the H-plane horn antenna are arranged On both sides of the central axis (ridge structure) of the dielectric substrate, the feed coaxial line is set on the side of the ridge structure close to the SIW structure; the SIW structure and the H-plane horn antenna include metal that is symmetrically distributed relative to the central axis (ridge structure) of the dielectric substrate The through holes 6 and the metal layers on the upper and lower surfaces of the dielectric substrate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com