Manufacturing industry workshop process planning system based on digital twinning

A technology for process planning and manufacturing, applied in the field of process planning systems for manufacturing workshops based on digital twins, can solve problems such as poor versatility and practicability, lack of process technology, and poor uniformity of information source management, to improve process level and production. ability, improve the efficiency of process preparation, and realize the effect of process knowledge modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

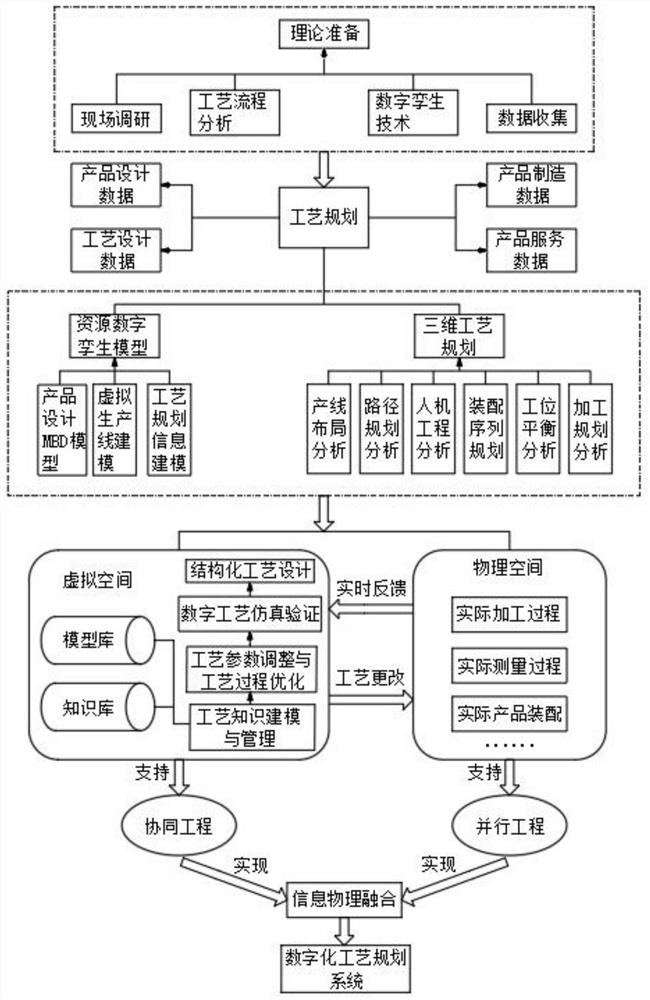

[0021] The embodiment of the present invention discloses a digital twin-based manufacturing workshop process planning system, as shown in the attached figure 1 As shown, it includes theoretical preparation, process planning, virtual space and physical space. Process planning is carried out through the theoretical preparation. The theoretical preparation includes on-site investigation, process flow analysis, digital twin technology and data collection. First, according to the on-site investigation and The existing process analysis, digital twin technology and data collection are theoretically prepared. According to the on-site investigation, according to the object-oriented method, use 3D software to model the manufacturing resource enterprise data including workshop and product data; workshop data includes , workshop general data, unit class and equipment class data; unit class data includes unit general data, workstation class and equipment class data.

[0022] The process pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com