Digital monitoring system and adjusting method for rotary kiln riding wheel shaft bearing bush

A monitoring system and supporting wheel shaft technology, applied in the field of rotary kiln bearing bush monitoring and maintenance, can solve the problems of large visual errors, labor and labor, etc., achieve timely feedback, ensure normal operation, and ingeniously conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

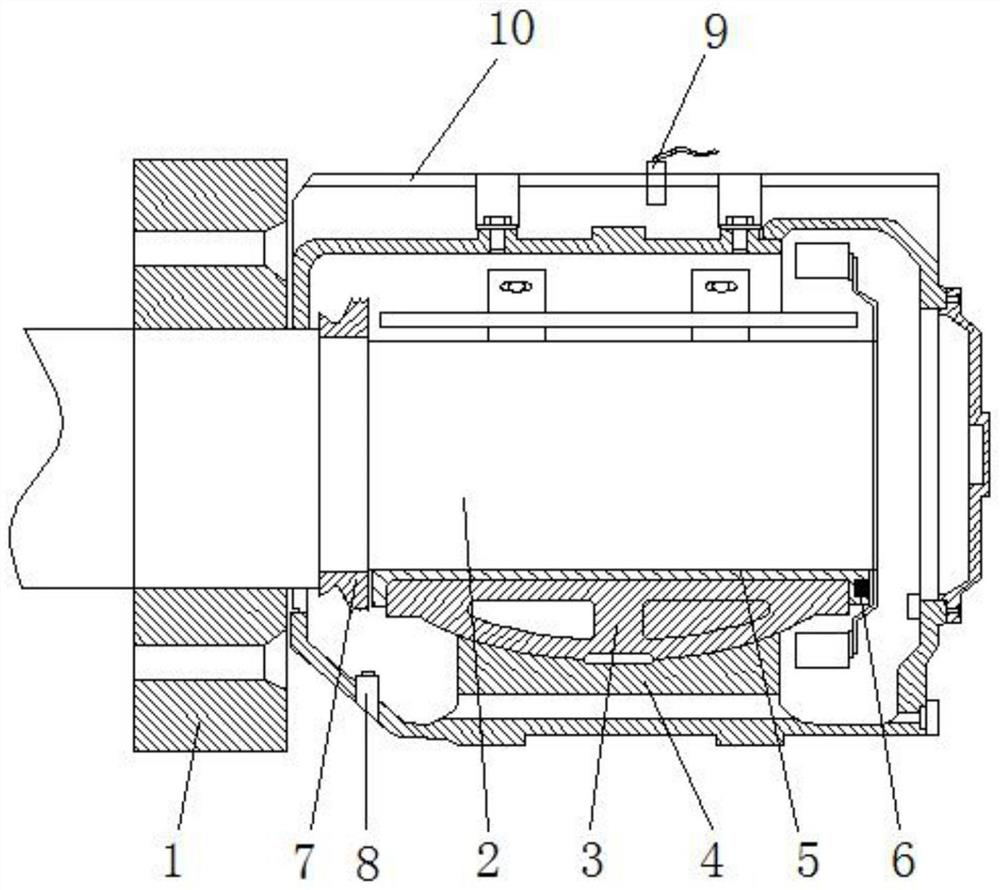

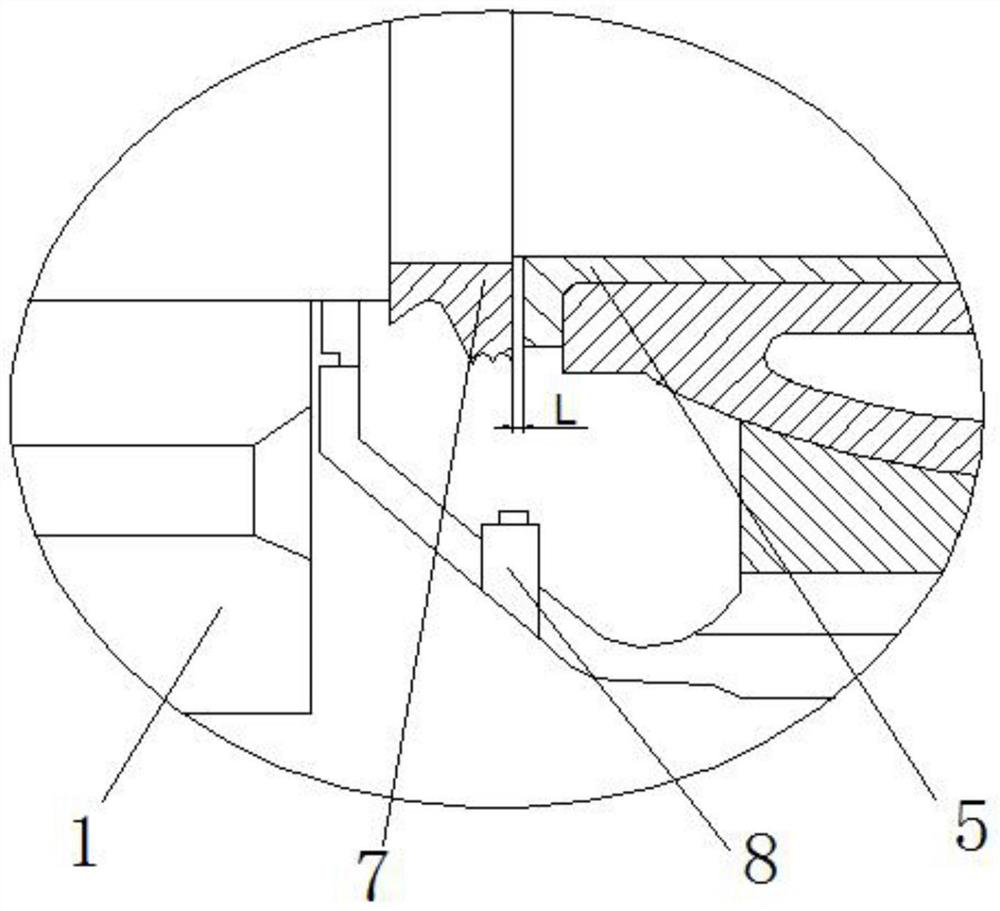

[0028] Such as Figure 1-2 As shown, a digital monitoring system for supporting wheel shaft and bushing of a rotary kiln includes a supporting wheel 1, a supporting wheel shaft 2, a sliding bearing and a bearing seat 4, and the two bearing seats 4 are arranged symmetrically with respect to the center of the rotary kiln, and the bearing seat 4 is fixed on the supporting base by bolts, the sliding bearing is arranged inside the bearing housing 4, the supporting wheel 1 is interference-connected to the supporting wheel shaft 2, and the supporting wheel shaft 2 acts on the sliding bearing , so that the supporting wheel shaft 2 and the supporting wheel 1 can rotate freely; the supporting wheel shaft 2 is provided with a thrust plate 7, and the thrust plate 7 is located on one side of the sliding bearing, and the other side of the sliding bearing An oil spoon is provided, and the oil spoon is connected to the support wheel shaft 2; a temperature sensor 6 is provided on the sliding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com