Mounting method of inclined supporting steel column

An installation method and technology of inclined steel pipe columns, applied in the direction of pillars, columns, pier columns, etc., can solve the problems of hidden safety hazards, lengthened construction period, and difficult calibration, so as to improve accuracy, reduce shaking, and reduce on-site calibration time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

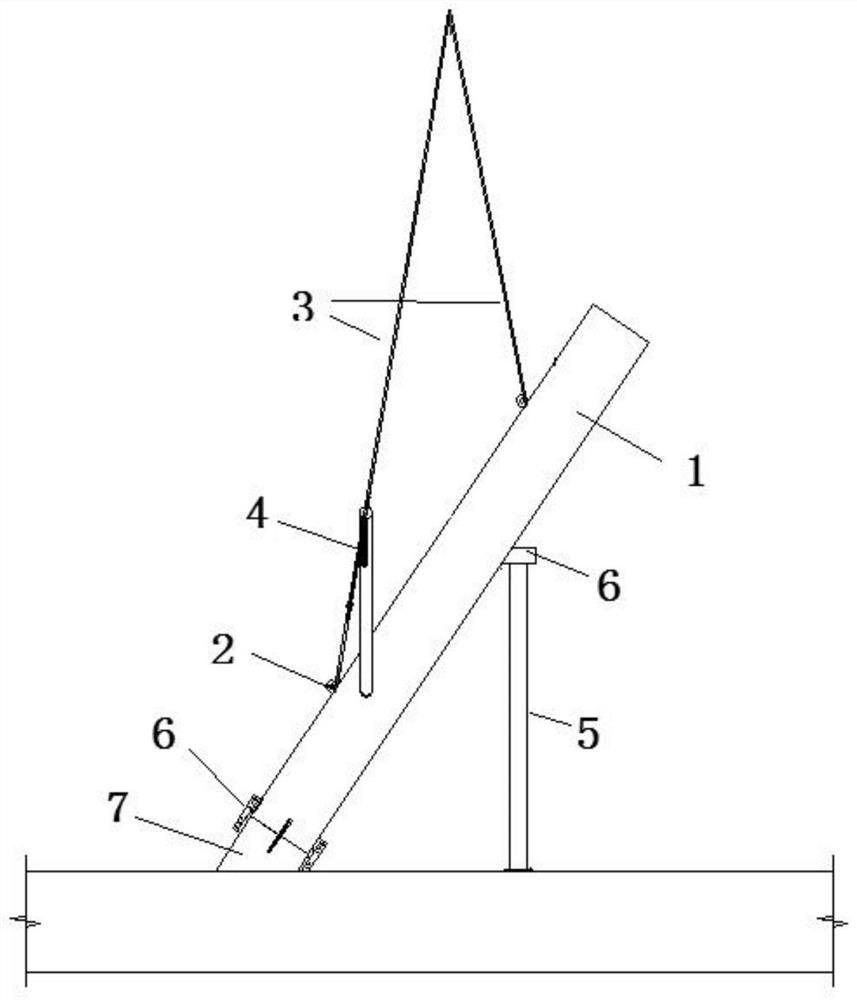

[0024] refer to Figure 1 to Figure 4 , this embodiment provides an installation method for inclined support steel columns, the method is to use modern information technology to obtain the precise coordinates of the key points of the components in place, and then use machinery to hoist the inclined steel column 1 and roughly adjust it to the design position through the reverse chain , the rotary machine is installed in place and temporarily connected with bolts. Through fine-tuning measures, under the observation of the three-dimensional space coordinates of high-precision instruments, the correction of the steel column is completed, and the subsequent structure is connected in time to form a stable system.

[0025] Specific steps are as follows:

[0026] 1) Determine the key points and calculate the precise coordinates of the key points

[0027] Determine the top end point and bottom end point of the upper end face of the inclined steel pipe column 1 as key points A and key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com