Mass concrete condensation system

A technology of mass concrete and condensing system, applied in the direction of infrastructure engineering, architecture, building construction, etc., can solve the problems of poor cooling effect, complex heat pump structure, unsuitable construction site, etc., to achieve practical and reliable, Water saving and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

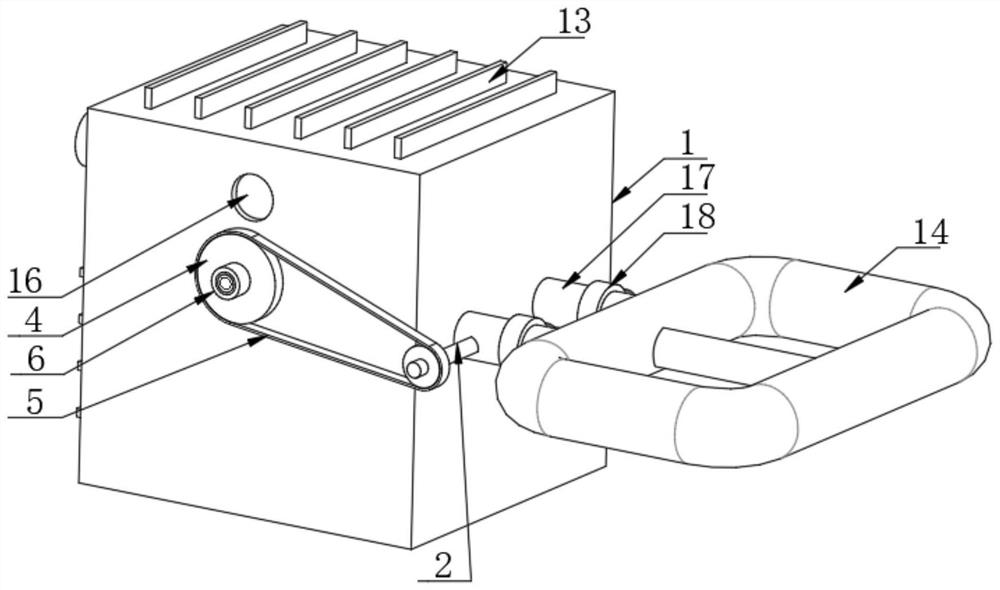

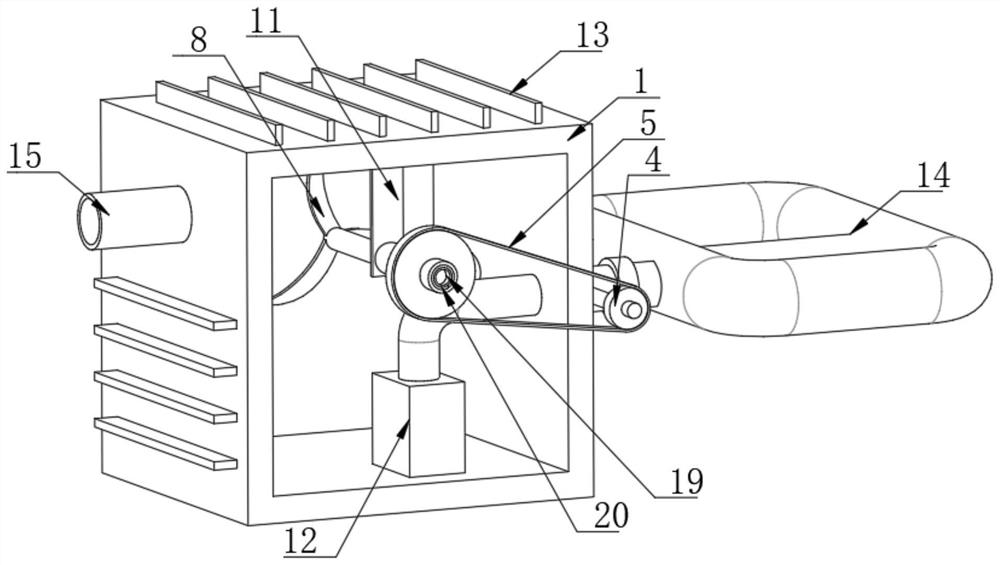

[0021] For the mass concrete condensing system provided by the embodiments of the present invention, please refer to figure 1 , figure 2 , image 3 and Figure 4 , comprising a box body 1 and a cooling tube 14 installed outside the box body 1 for cooling the concrete. The cooling tube 14 can cool and condense the concrete when it is inserted into the concrete or moves in the concrete, or , before pouring, the cooling pipe 14 is directly placed in the middle of the tank storing concrete for central cooling, and the temperature difference after the concrete flows out is as small as possible. The difference is smaller, and the performance of concrete is more uniform after forming. One side of the box body 1 is provided with a rotating rod 2, the outer side of the rotating rod 2 is fixedly connected with the impeller 3, and the outer side of the rotating rod 2 is fixedly connected with the belt pulley 4, and the number of the belt pulleys 4 is set to two. A belt 5 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com