High-ductility soluble magnesium-lithium alloy and preparation method and application thereof

A magnesium-lithium alloy and ductility technology, applied in the field of magnesium-lithium alloys, can solve the problems of incomplete degradation of rubber cartridges and low ductility of sealing tools, and achieve the effects of improving plasticity, refining grains and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

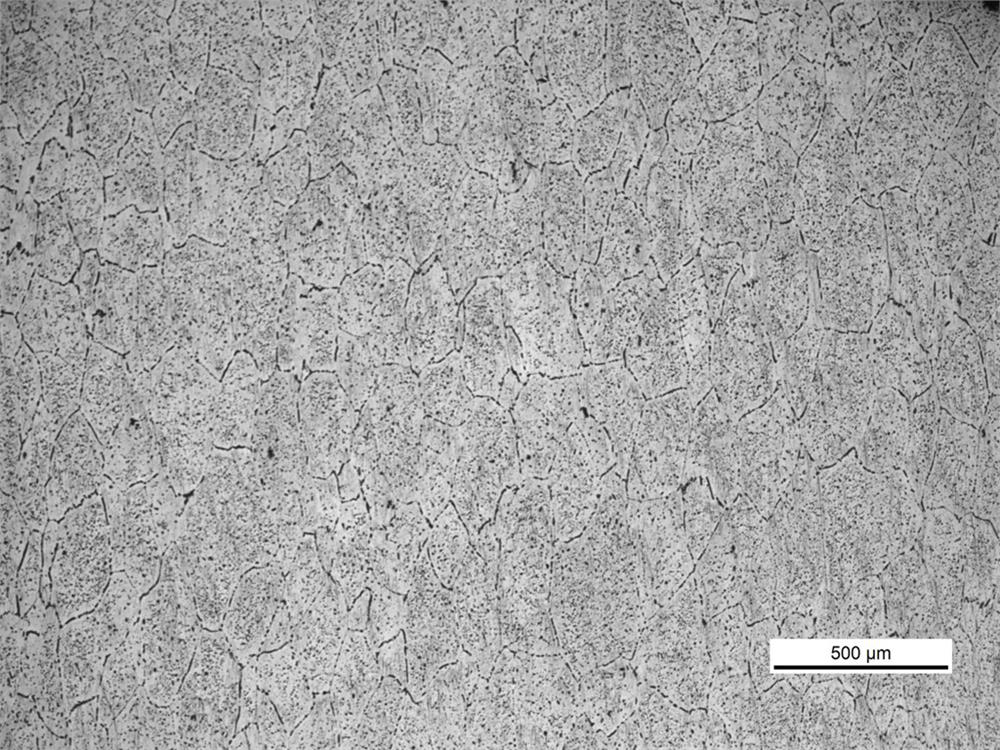

Image

Examples

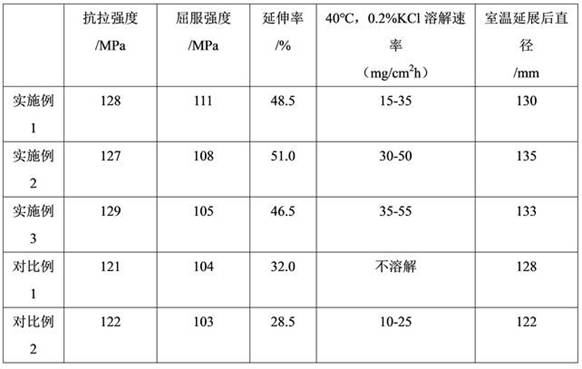

Embodiment 1

[0034] A high ductility soluble magnesium-lithium alloy consisting of the following components in mass percentage: Li: 9.0%, Al: 0.3%, Zn: 0.2%, Ni: 0.4%, Cu: 0.3%, Gd+Y+Ce ≤0.2%, the impurity elements Na and K are less than 0.001%, the balance is Mg and unavoidable impurities; the mass ratio of Gd, Y, and Ce is: 1:1:2.

[0035] The preparation method of the high-ductility soluble magnesium-lithium alloy, the specific steps are as follows:

[0036] (1) Preparation of ingots: Take pure lithium ingots, pure magnesium ingots, pure aluminum ingots, pure zinc ingots, Mg-30Ni master alloys, Al-50Cu master alloys, Mg-30Y master alloys, Mg-30Gd master alloys and Mg- 30Ce intermediate alloy, and carry out batching according to the mass percentage of each component in the alloy, adopt vacuum furnace to carry out alloy casting, obtain ingot (wherein the casting method adopts existing technology, and is not the innovation point of the present invention, so no longer repeat);

[0037] (2) ...

Embodiment 2

[0042] A high ductility soluble magnesium-lithium alloy consisting of the following components in mass percentage: Li: 11.5%, Al: 0.5%, Zn: 0.6%, Ni: 0.7%, Cu: 0.6%, Gd+Y+Ce ≤0.2%, the impurity elements Na and K are less than 0.001%, and the balance is Mg and unavoidable impurities; the mass ratio of Gd, Y, and Ce is: 1:1:4.

[0043] The preparation method of the high-ductility soluble magnesium-lithium alloy, the specific steps are as follows:

[0044] (1) Preparation of ingots: Take pure lithium ingots, pure magnesium ingots, pure aluminum ingots, pure zinc ingots, Mg-30Ni master alloys, Al-50Cu master alloys, Mg-30Y master alloys, Mg-30Gd master alloys and Mg- The 30Ce master alloy is mixed according to the mass percentage of each component in the alloy, and the alloy is cast in a vacuum furnace to obtain an ingot;

[0045] (2) Large plastic deformation at low temperature: The ingot obtained in step (1) is turned to remove the scale on the surface of the ingot, heated to 2...

Embodiment 3

[0049] A high ductility soluble magnesium-lithium alloy consisting of the following components in mass percentage: Li: 10.0%, Al: 1.2%, Zn: 0.5%, Ni: 0.5%, Cu: 0.5%, Gd+Y+Ce ≤0.2%, the impurity elements Na and K are less than 0.001%, the balance is Mg and unavoidable impurities; the mass ratio of the three elements Gd, Y, and Ce is: 1:2:1.

[0050] The preparation method of the high-ductility soluble magnesium-lithium alloy, the specific steps are as follows:

[0051] (1) Preparation of ingots: Take pure lithium ingots, pure magnesium ingots, pure aluminum ingots, pure zinc ingots, Mg-30Ni master alloys, Al-50Cu master alloys, Mg-30Y master alloys, Mg-30Gd master alloys and Mg- The 30Ce master alloy is mixed according to the mass percentage of each component in the alloy, and the alloy is cast in a vacuum furnace to obtain an ingot;

[0052] (2) Large plastic deformation at low temperature: The ingot obtained in step (1) is turned to remove the oxide skin on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com