Soy sauce residue glyceride, agricultural vegetable oil emulsion as well as preparation method and application thereof

A technology of soy sauce residue and glyceride, which is applied in the field of pesticides, can solve the problems of increasing the amount of chemical pesticides used, phytotoxic spots on fruit surfaces or leaves, poor emulsification effect, etc., achieves good insect and disease prevention effects, and reduces the damage of diseases and insects. , good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

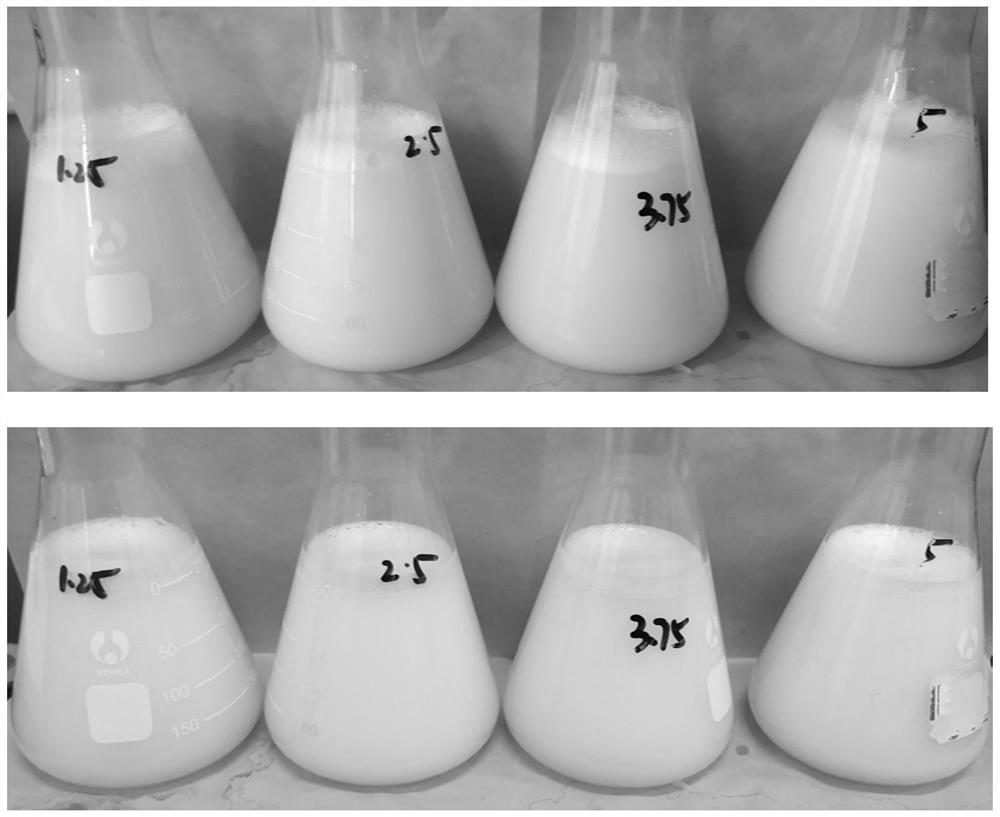

Image

Examples

Embodiment 1

[0051] The mass percent content of each component of an agricultural vegetable oil emulsion is: 85.0% of soy residue glyceride, 7.0% of emulsifier, 0.02% of antioxidant, and 7.98% of auxiliary agent.

[0052] Wherein, the preparation method of soy sauce residue glyceride is: add 5.0% diethylene glycol butyl ether to the oil extracted from soy sauce residue, add 5% Lipozyme RM IM For lipase, the oil and glycerol extracted from soy sauce residues are used in a mass ratio of 10:1, first reacted at 65°C for 1h, then lowered the temperature to 45°C for 6h, stirred continuously during the reaction, and then placed At about 0°C for 6 hours, filter out the crystals, and then separate the glyceride from soy sauce residue through a filter screen with a pore size of 200 mesh for later use.

[0053] Among them, the emulsifier is cardanol polyoxyethylene ether-9 and sophorolipid, the mass ratio is 2.0:1.0, and they are mixed for later use; the antioxidant is 0.02% tert-butylhydroquinone; t...

Embodiment 2

[0056] The mass percent content of each component of an agricultural vegetable oil emulsion is: 90.0% of soy residue glyceride, 5.0% of emulsifier, 0.02% of antioxidant, and 4.98% of auxiliary agent.

[0057] Wherein, the preparation method of soy sauce residue glyceride is: add 6.0% diethylene glycol propyl ether to the fat extracted from soy sauce residue, add 5% Lipozyme RM IM For lipase, the oil and glycerol extracted from soy sauce residues are used in a mass ratio of 10:1, first reacted at 65°C for 1h, then lowered the temperature to 45°C for 6h, stirred continuously during the reaction, and then placed At about 0°C for 6 hours, filter out the crystals, and then separate the glyceride from soy sauce residue through a filter screen with a pore size of 200 mesh for later use.

[0058] Among them, the emulsifier is cardanol polyoxyethylene ether-9, modified oil ethoxylate and sophorolipid, and the mass ratio is 1.0:1.0:1.0, which is mixed for later use; the antioxidant is 0...

Embodiment 3

[0061] The mass percent content of each component of an agricultural vegetable oil emulsion is: 90.0% of soy residue glyceride, 7.0% of emulsifier, 0.01% of antioxidant, and 2.99% of auxiliary agent.

[0062] Wherein, the preparation method of soy sauce residue glyceride is: add 6.0% butyl acetate to the fat extracted from soy sauce residue, add 5% Lipozyme RM IM For lipase, the oil and glycerol extracted from soy sauce residues are used in a mass ratio of 10:1, first reacted at 65°C for 1h, then lowered the temperature to 45°C for 6h, stirred continuously during the reaction, and then placed At about 0°C for 6 hours, filter out the crystals, and then separate the glyceride from soy sauce residue through a filter screen with a pore size of 150 mesh for later use.

[0063] Among them, the emulsifier is cardanol polyoxyethylene ether-9 and sophorolipid, the mass ratio is 2.0:1.0, and they are mixed for later use; the antioxidant is 0.01% fat-soluble rosemary extract; the auxilia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com