Waterproof breathable composite net, and preparation method and application thereof

A waterproof, breathable, mesh technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

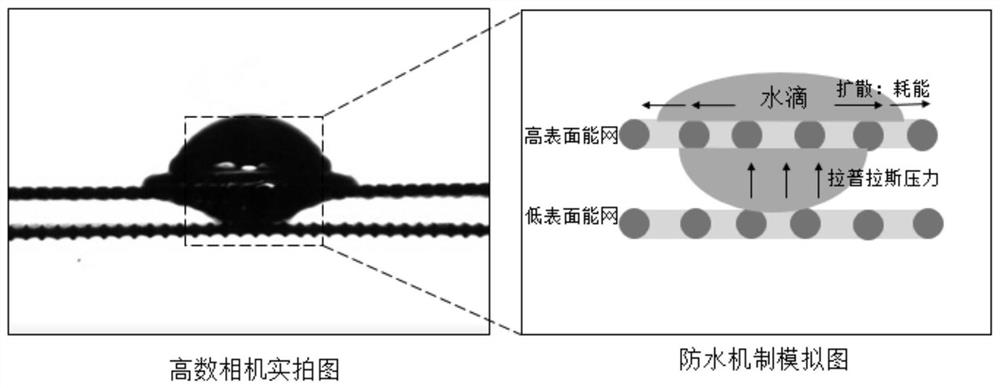

Problems solved by technology

Method used

Image

Examples

Embodiment 1

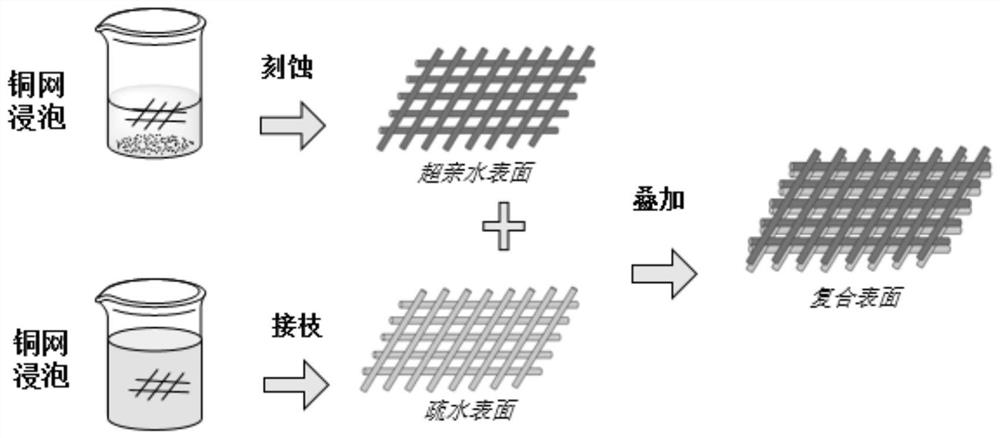

[0039] A method for preparing a waterproof and breathable composite net, comprising the following steps:

[0040] (1) Select the two-layer mesh with 60 meshes to weave copper mesh, first use acetone to ultrasonically wash for 30 minutes, and then use deionized water to ultrasonically wash for 30 minutes to obtain a clean copper mesh;

[0041] (2) one layer of clean copper mesh of step (1) gained is etched 5min in the mixed solution of sodium hydroxide and ammonium persulfate, then dries, obtains the high superhydrophilic copper mesh of surface energy, wherein, The concentration of sodium hydroxide in the mixed solution is 5mol / L, and the concentration of ammonium persulfate is 0.2mol / L;

[0042] (3) Soak another layer of clean copper mesh obtained in step (1) in the ethanol solution of n-dodecylmercaptan for 1h, and then dry to obtain a hydrophobic copper mesh with low surface energy. Dialkyl mercaptan quality is 5% of ethanol quality;

[0043] (4) Use the superhydrophilic c...

Embodiment 2

[0046]A method for preparing a waterproof and breathable composite net, comprising the following steps:

[0047] (1) Select two layers of nylon nets with meshes of 120 mesh, first use acetone to ultrasonically wash for 30 minutes, and then use deionized water to ultrasonically wash for 30 minutes to obtain a clean nylon net;

[0048] (2) Utilize the spray gun to spray the hydrophilic solvent on the front and back sides of one layer of clean nylon net obtained in step (1), to obtain super-hydrophilic nylon net, wherein the hydrophilic solvent is obtained by adding 0.4g TiO 2 Add nanoparticles and 0.05g polyurethane to 20ml acetone solution, and magnetically stir for 1 hour to prepare;

[0049] (3) Use a spray gun to spray a hydrophobic solvent on the front and back sides of another layer of clean nylon net obtained in step (1) to obtain a superhydrophobic nylon net, wherein the hydrophobic solvent is obtained by mixing polyvinylidene fluoride, hydrophobic It is prepared by mix...

Embodiment 3

[0052] A method for preparing a waterproof and breathable composite net, comprising the following steps:

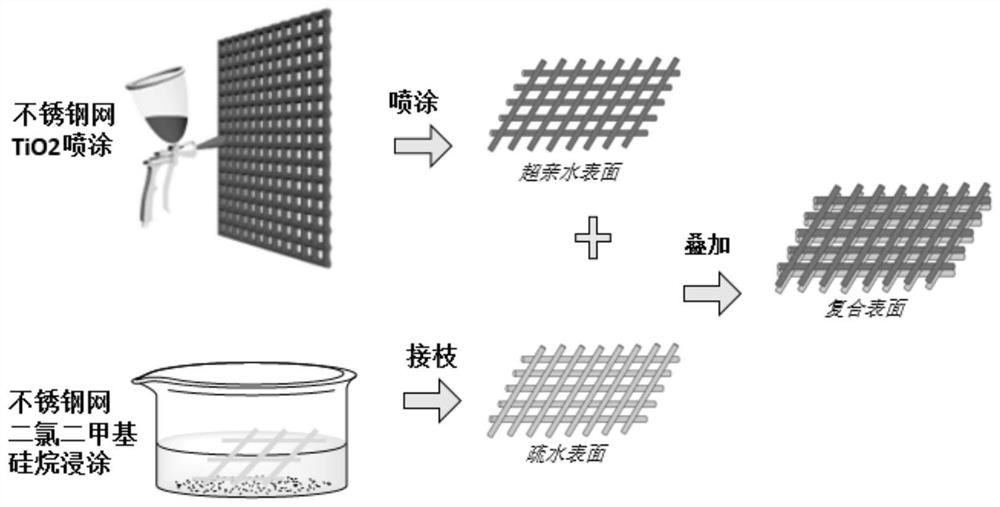

[0053] (1) Select two layers of perforated stainless steel mesh with a mesh size of 300 mesh, first use acetone to ultrasonically wash for 30 minutes, and then use deionized water to ultrasonically wash for 30 minutes to obtain a clean stainless steel mesh;

[0054] (2) Utilize the spray gun to spray the hydrophilic solvent on the front and back sides of one layer of clean stainless steel mesh obtained in step (1), to obtain the superhydrophilic stainless steel mesh, wherein the hydrophilic solvent is obtained by adding 0.4gTiO 2 Add nanoparticles and 0.05g polyurethane to 20ml acetone solution, and magnetically stir for 1 hour to prepare;

[0055] (3) cleaning another layer of clean stainless steel mesh oxygen plasma of step (1) gained for 20min, then grafting reaction in the grafting reaction solution for 30min, and then drying to obtain the hydrophobic stainless steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com