Light interior wall partition strip plate production equipment

A technology for production equipment and spacers, which is applied in the field of production equipment for lightweight interior wall spacers, and can solve problems such as unfavorable rapid production and large time spans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

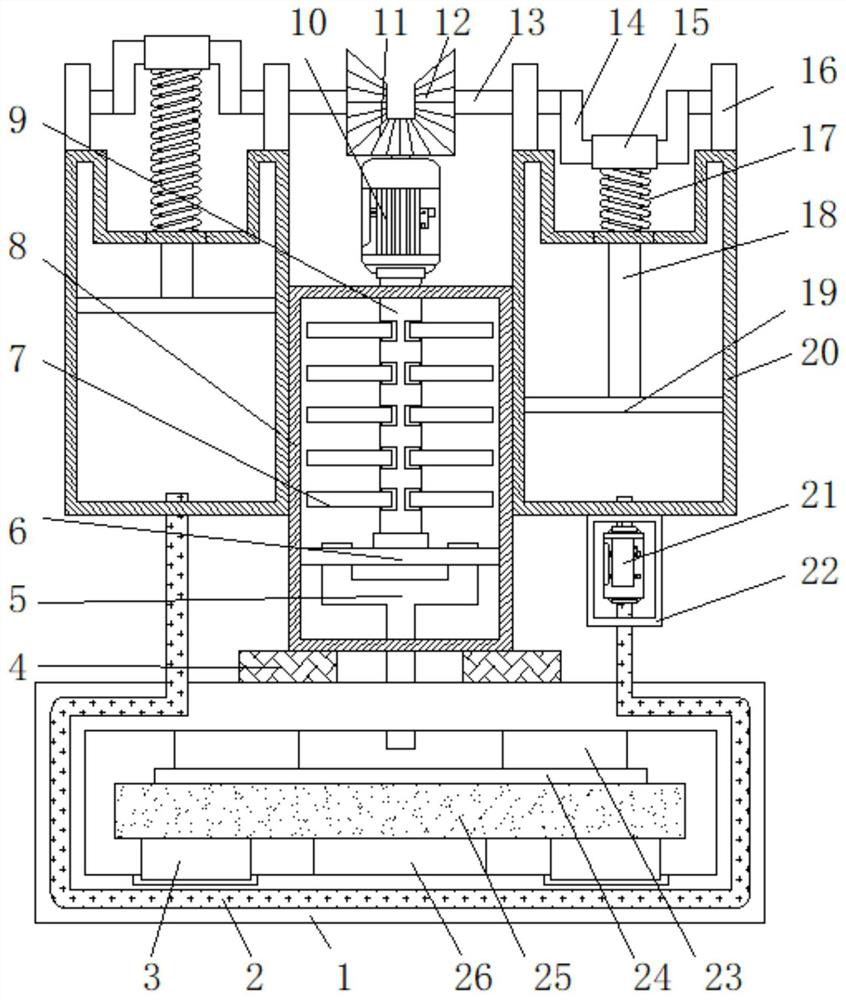

[0030] Embodiment 1: as figure 1 As shown, a kind of light-weight interior wall spacer panel production equipment that the present invention proposes comprises a first box body 1, and first fixing block 4 is welded on both sides of the top of the first box body 1, and the first fixing block 4 The top is welded with a second box body 8, the inner walls of both sides of the second box body 8 are welded with fixed plates 6, the top of the second box body 8 is fixedly connected with a motor 10, and the bottom output end of the motor 10 is welded to penetrate and extend to the second box body. The stirring roller 9 in the second casing 8, the outer ring of the stirring roller 9 is welded with a plurality of glue rods 7, and the stirring roller 9 is positioned at one end in the second casing 8 and is connected to the top of the fixed plate 6 for rotation;

Embodiment 2

[0031] Embodiment 2: as figure 1As shown, the top output end of the motor 10 is welded with a first bevel gear 11, both sides of the second box body 8 are welded with a third box body 20, and both sides of the top of the third box body 20 are welded with a stabilizing block 16, The sides of the stabilizing blocks 16 close to each other are rotatably connected to the crankshaft 14, the ends of the crankshafts 14 close to each other are welded with the rotating shaft 13, the ends of the rotating shaft 13 close to each other are welded with the second bevel gear 12, and the outer ring of the crankshaft 14 is sleeved with a sleeve 15. The bottom of the sleeve 15 is welded with a movable rod 18 that penetrates and extends into the third box body 20. The bottom of the sleeve 15 is welded with a first spring 17 sleeved on the outer ring of the movable rod 18. The first spring 17 is away from the One end of the sleeve pipe 15 is welded to the top of the third box body 20, and the end ...

Embodiment 3

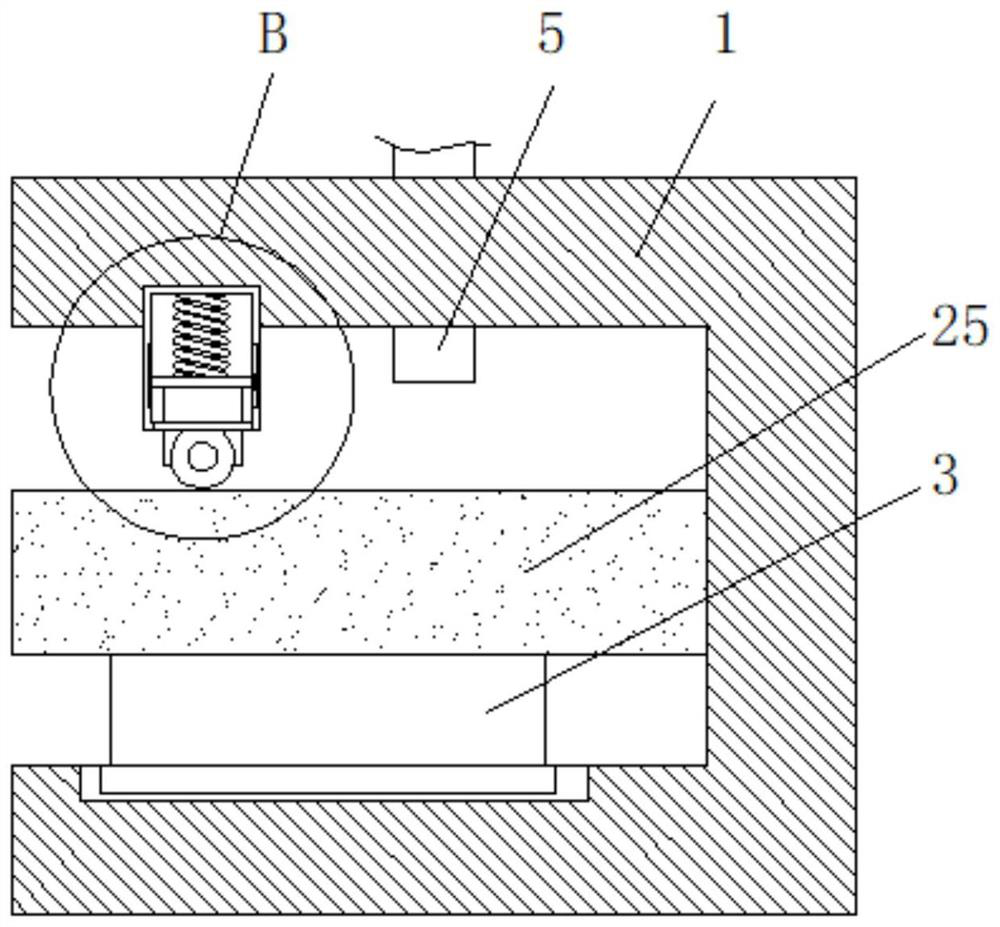

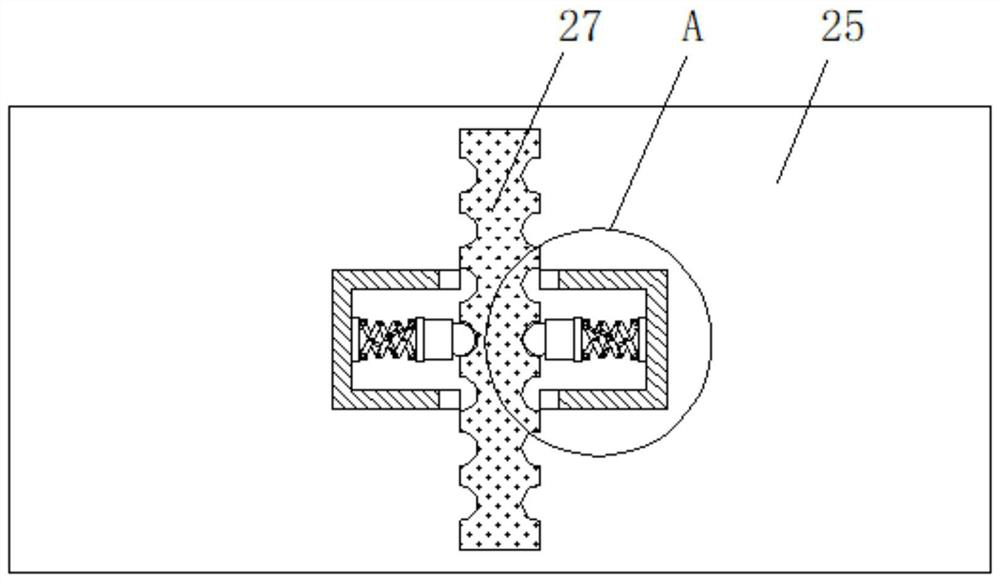

[0032] Embodiment 3: as figure 1 , Figure 5 As shown, the bottom of the third box body 20 on the right is welded with a frame 22, and the top inner wall of the frame 22 is fixedly connected with a refrigerator 21, and the water inlet end of the refrigerator 21 runs through and extends into the third box body 20, and the refrigerator 21 The outlet end of the water outlet is sleeved with a condensation pipe 2 that penetrates and extends into the first box body 1. One end of the condensation pipe 2 located in the first box body 1 is socketed with the bottom of the third box body 20 on the left side. The first box body The top inner wall of 1 is welded with a fourth box body 23, the top inner wall of the fourth box body 23 is welded with a second spring 31, and the other end of the second spring 31 is welded with a sliding connection with the inner walls of both sides of the fourth box body 23. Plate 33, the side of the movable plate 33 away from the second spring 31 is welded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com