Carbon nanotube-in-tube@antimony sulfide/antimony composite material and preparation method and application thereof

A technology of carbon nanotubes and composite materials, applied in the field of lithium-ion batteries, can solve problems such as damage reaction kinetics, achieve the effects of suppressing losses, maintaining integrity, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

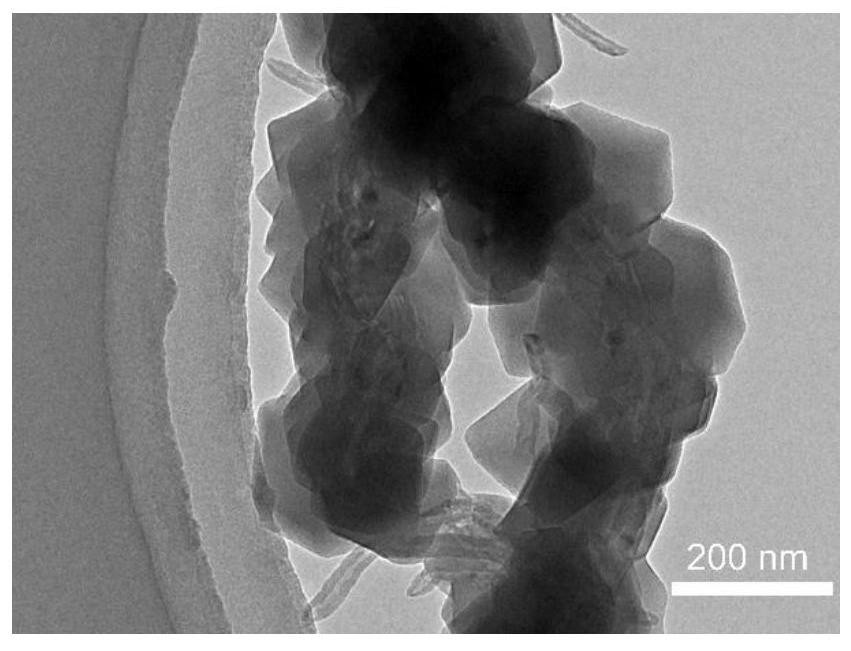

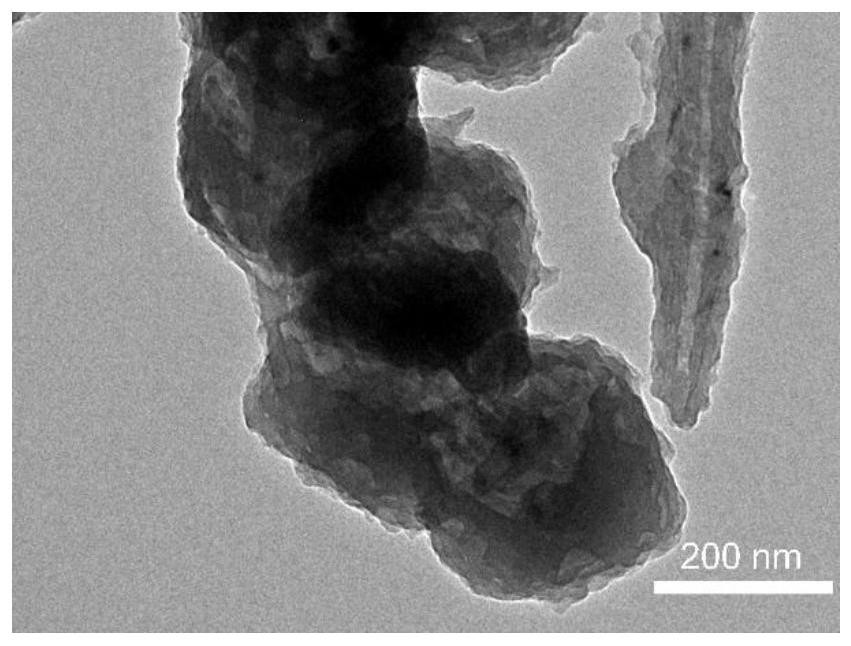

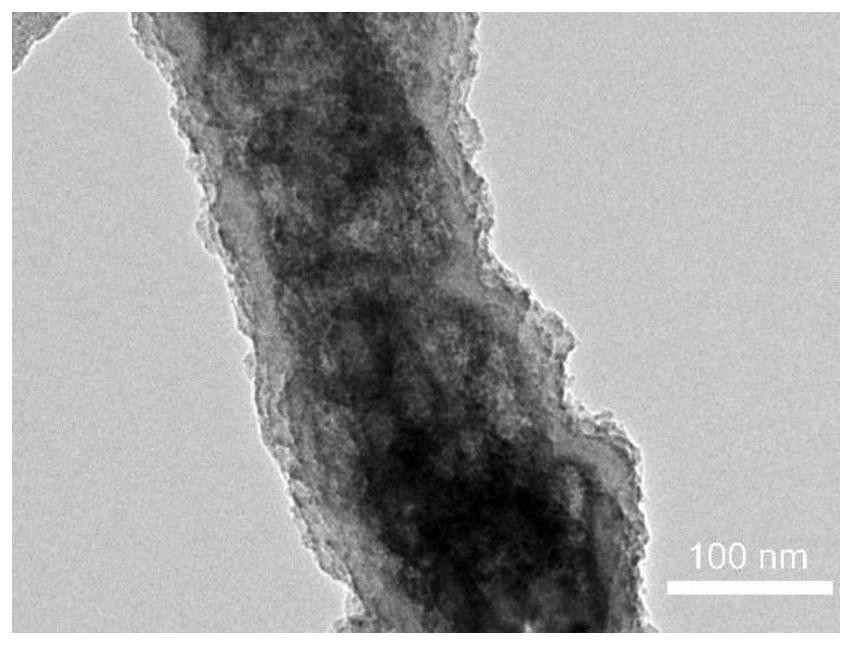

Image

Examples

Embodiment 1

[0042] (1) Preparation of solution A: ultrasonically disperse 28 mg of acidified carbon nanotubes (CNTs) with an outer diameter of 30-60 nm in 5 ml of methanol. Preparation solution B: 0.8g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 14ml methanol. Preparation solution C: 2.17 g of 2-methylimidazole was dissolved in 14 ml of methanol. Pour solution B into solution C quickly under stirring conditions to form a uniform precursor solution, and then pour it into solution A after a few minutes. Then, the obtained homogeneous solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was placed in an oven at 90°C for 6 h, and then naturally cooled to room temperature in the oven. The product was separated by centrifugation, washed several times with methanol, and dried at 60°C to obtain CNTs@ZIF-8.

[0043] (2) Ultrasonic dispersion of 100mg CNTs@ZIF-8 in 10ml ethanol. 230 mg of cetyltrimethylammonium bromide (CTAB) was dissolved in 30 ml...

Embodiment 2

[0051] (1) Preparation of solution A: ultrasonically disperse 28 mg of acidified carbon nanotubes (CNTs) with an outer diameter of 30-60 nm in 5 ml of methanol. Preparation solution B: 0.8g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 14ml methanol. Preparation solution C: 2.17 g of 2-methylimidazole was dissolved in 14 ml of methanol. Pour solution B into solution C quickly under stirring conditions to form a uniform precursor solution, and then pour it into solution A after a few minutes. Then, the obtained homogeneous solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was placed in an oven at 110° C. for 6 h, and then naturally cooled to room temperature in the oven. The product was separated by centrifugation, washed several times with methanol, and dried at 60°C to obtain CNTs@ZIF-8.

[0052] Subsequent process is identical with embodiment 1.

[0053] The structure of the product carbon nanotube middle tube@antimony sulf...

Embodiment 3

[0056] (1) Preparation of solution A: ultrasonically disperse 28 mg of acidified carbon nanotubes (CNTs) with an outer diameter of 30-60 nm in 5 ml of methanol. Preparation solution B: 0.8g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 14ml methanol. Preparation solution C: 2.17 g of 2-methylimidazole was dissolved in 14 ml of methanol. Pour solution B into solution C quickly under stirring conditions to form a uniform precursor solution, and then pour it into solution A after a few minutes. Then, the obtained homogeneous solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was placed in an oven at 90°C for 6 h, and then naturally cooled to room temperature in the oven. The product was separated by centrifugation, washed several times with methanol, and dried at 60°C to obtain CNTs@ZIF-8.

[0057] (2) Ultrasonic dispersion of 100mg CNTs@ZIF-8 in 10ml ethanol. 340 mg of cetyltrimethylammonium bromide (CTAB) was dissolved in 30 ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com