Water returning device with double-S-bend water seal

A water return device and curved water technology, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of easily damaged joints, low energy utilization rate, high production cost, etc., and reduce maintenance Cost, increase water seal effect, reduce energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

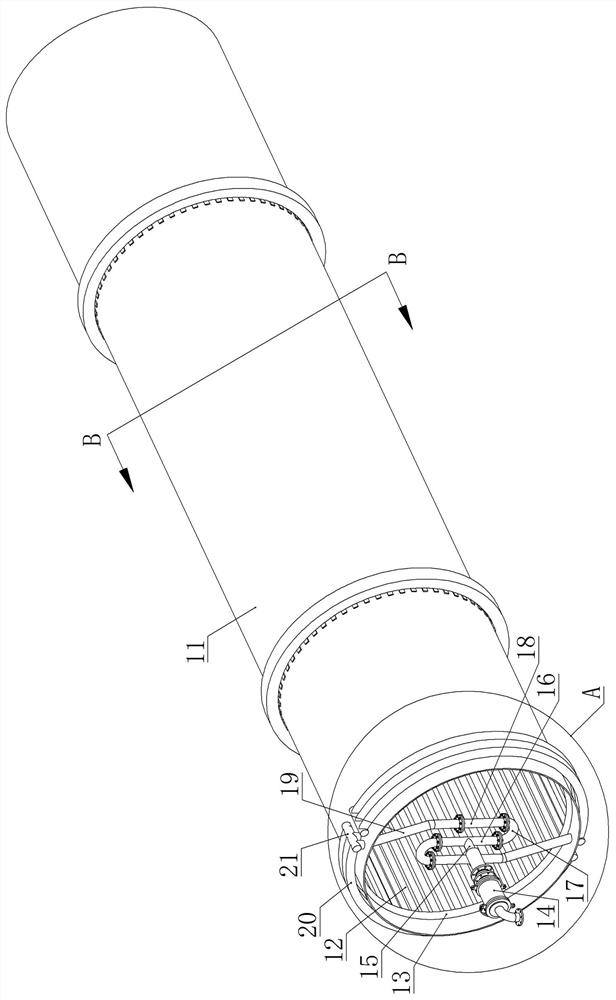

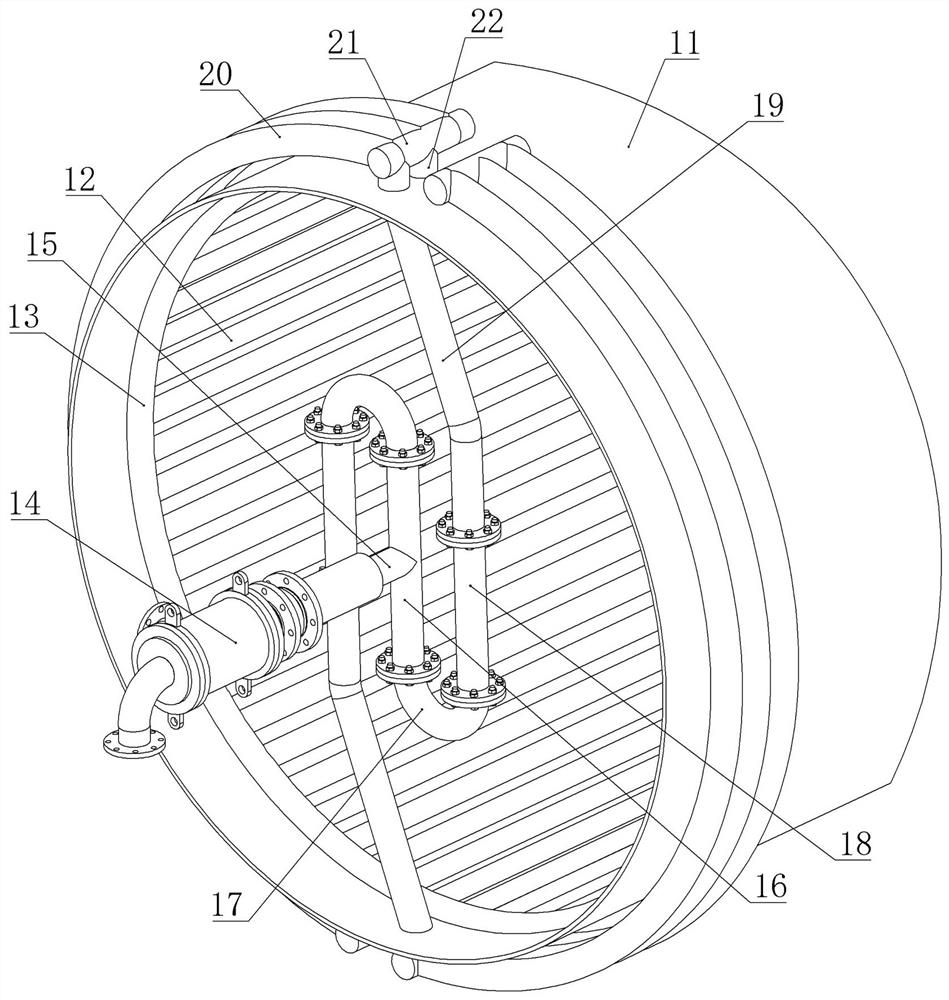

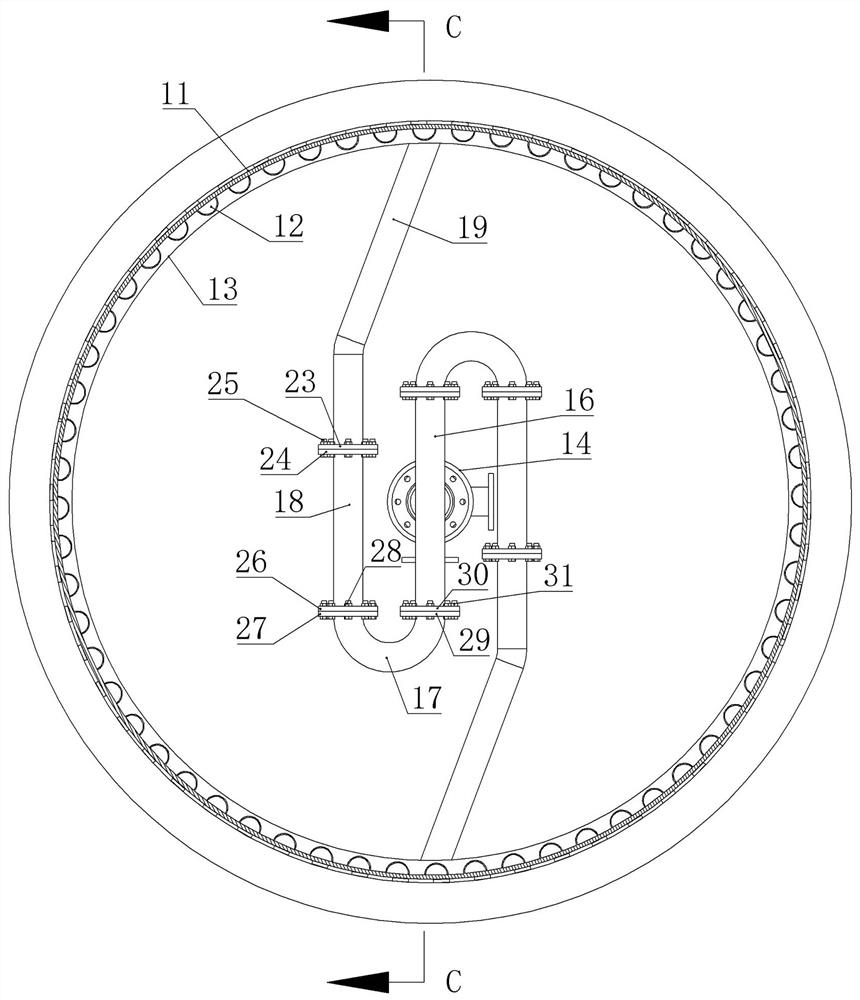

[0025] Example 1, see Figure 1-8 The returning device with double S bending water seal, the device is mounted on the end of the drum including a rotary joint, a returning pipe group mounted between the rotary joint and the drum;

[0026] The returning pipe group includes a split tube, a flexible steam catheter, and a U-water seal, which is disposed at one end of the drum coaxial, and the inner end seal of the exhaust pipe on the rotary joint is fixed. The middle stage of the dispensing tube, and the above-described exhaust pipe is connected to the distribution tube, and the U-type water sealing tube in which it is internally communicated with the dispensing pipe is sealed, and the free end of each U-water seal tube is sealed. The flexible steam catheter is fixed to its internal communication, the free end seal of the flexible steam catheter fixes a split tube in which the internal communication thereof is fixed, and the free end seal of the transfer tube is fixed to the first gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com