Energy collector

An energy harvester and vibration energy technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of low output voltage, complex processing and assembly, etc., and achieve the effects of high output voltage, reliable electrical connection, and increased output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

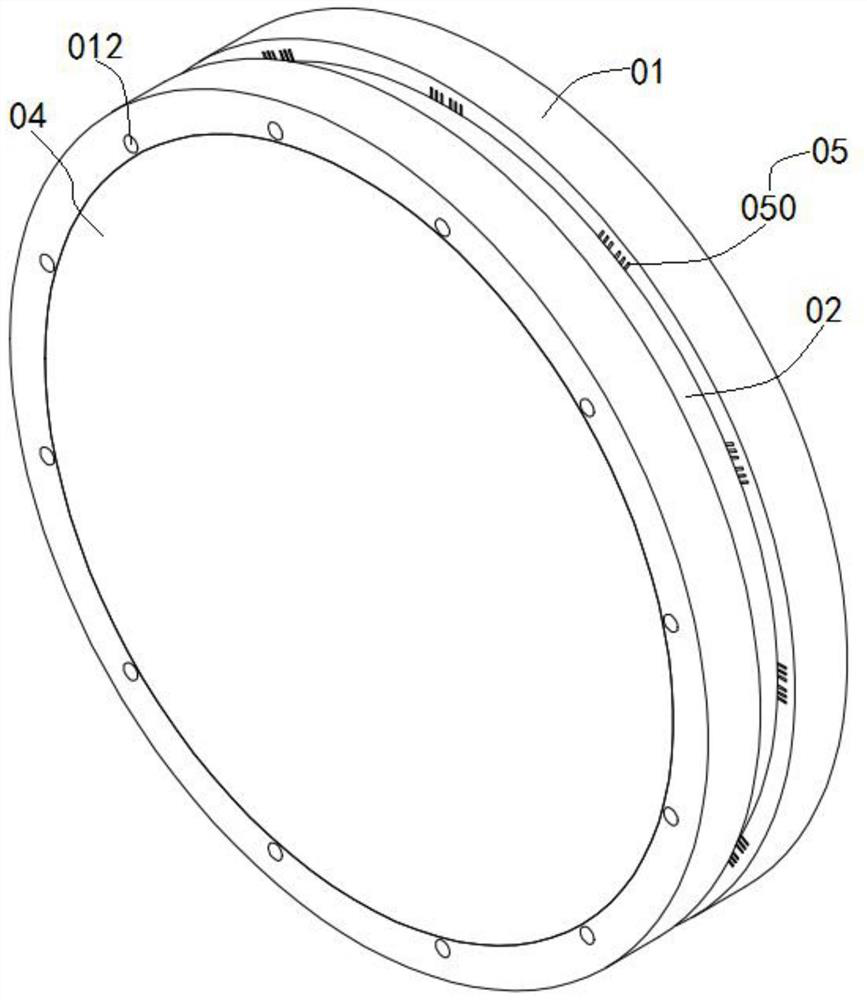

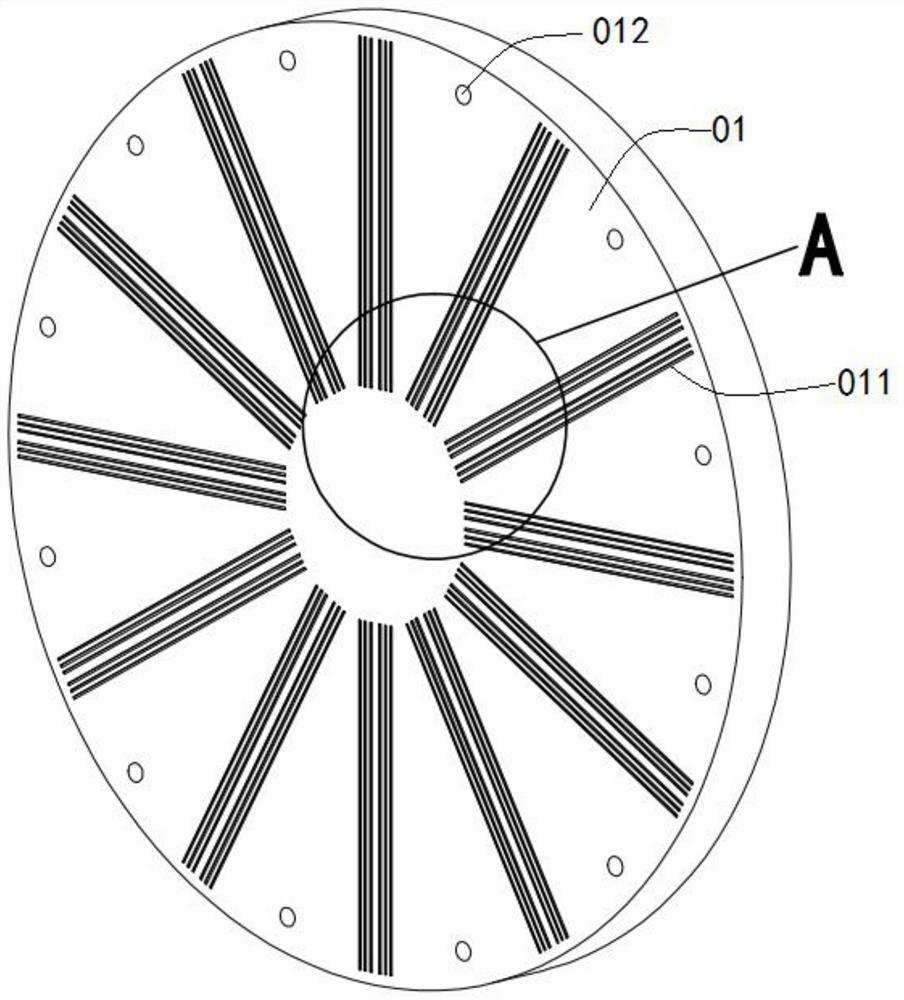

[0037] See attached Figure 1-8 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention. The present invention specifically discloses an energy harvester that is electrically connected to an external load and converts environmental vibration energy into electrical energy, including:

[0038] Cover plate 01, there are two cover plates 01 arranged opposite to each other;

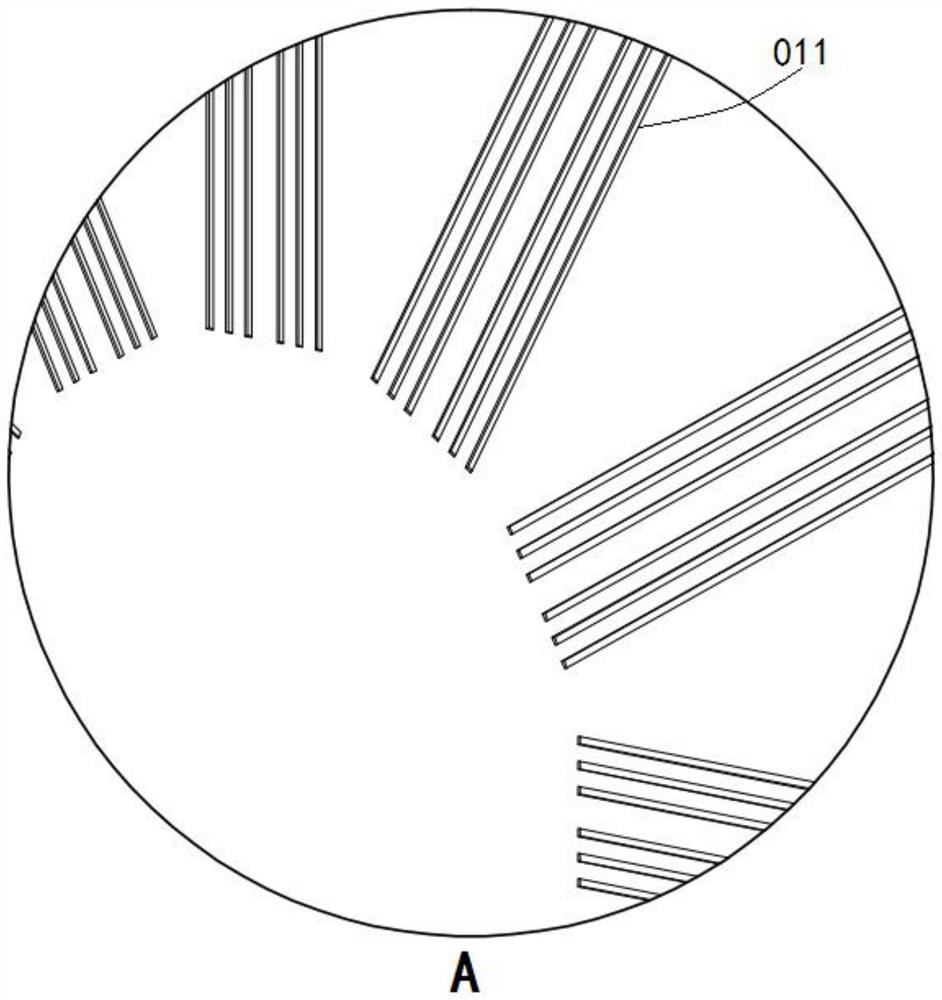

[0039] Limiting plate 02, the limiting plate 02 is arranged parallel to the cover plate 01 and it is located between the two cover plates 01, and there are a plurality of elongated limiting through holes 020 radially distributed on the limiting plate 02, the limiting The two sides of the plate 02 are in sealing contact with the plate surface of the cover plate 01 respectively, and the position corresponding to the limit through hole 020 forms an accommodation chamber, and the interior of the accommodation chamber is partially filled with room temperature liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com