Double-effect water chiller

A chiller and condenser technology, applied in the directions of refrigerators, refrigeration and liquefaction, heating and refrigeration combinations, etc., can solve the problems of many equipment, poor automatic control, and excessive energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing

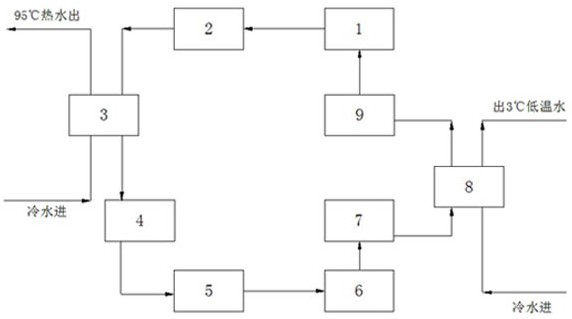

[0015] The refrigerant gas enters the oil separator 2 after being compressed by the high-pressure ratio compressor 1, and after separating the lubricating oil, it enters the multi-stage horizontal plate-exchange condenser 3, exchanges heat with the water in the plate-exchange condenser, and heats the water When the temperature reaches 95°C, the temperature of the refrigerant is greatly reduced, and the gas is condensed into a liquid, which enters the liquid receiver 4, and then flows through the dry filter 5, and then enters the sub-cooler 6 to further cool down after drying the water, preparing for low-temperature evaporation , and then enter the multi-stage horizontal plate exchange evaporator 8 to evaporate through the expansion valve 7 and reduce the pressure, fully absorb the heat of the water in the evaporator, reduce the water temperature to 3°C, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com