Protective glass for glass curtain wall

A glass curtain wall and glass technology, applied to walls, building components, buildings, etc., can solve the problems of high maintenance cost, inconvenient glass replacement of glass curtain wall, poor heat and sound insulation effect of glass curtain wall, etc., to reduce maintenance cost and avoid heat insulation The sound insulation effect is poor, and the effect of improving the convenience of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

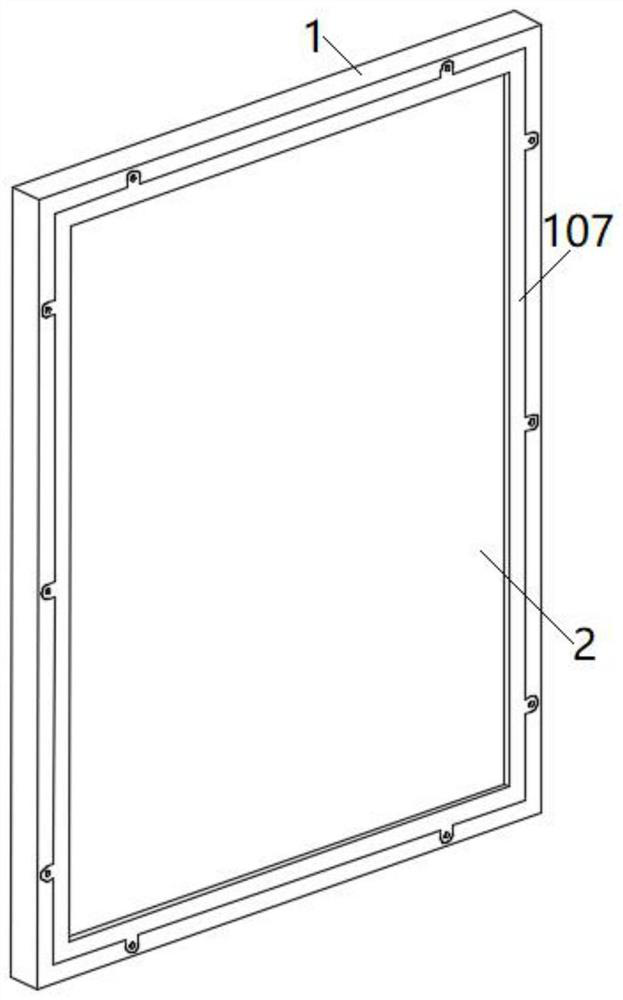

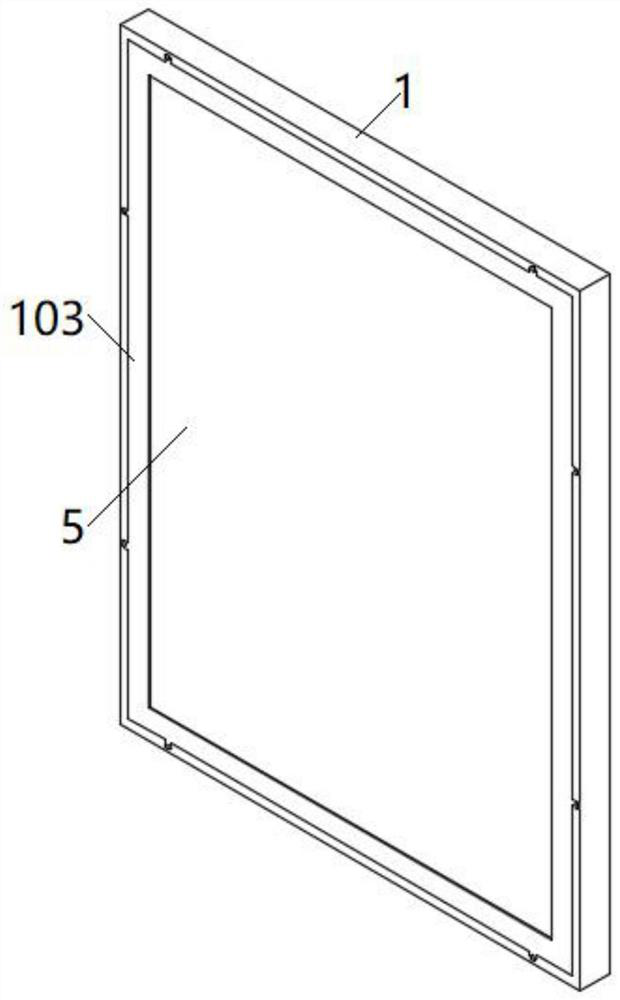

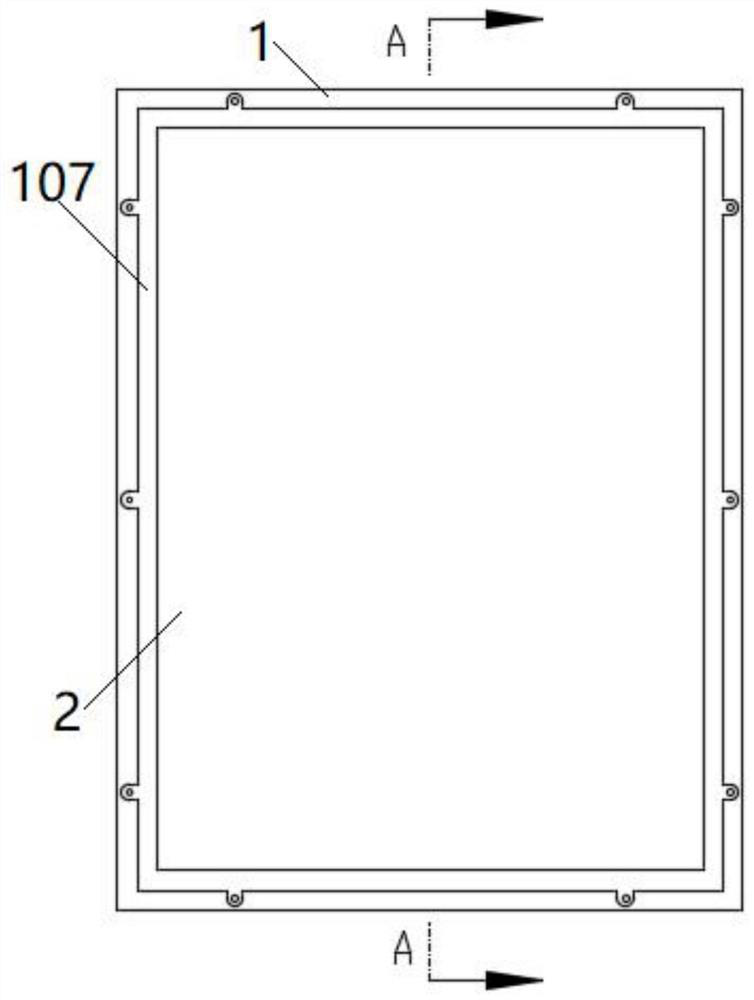

[0033] see Figure 1-3 As shown, the present invention is a protective glass for a glass curtain wall, comprising an encapsulation frame 1 , an outer glass 2 , a color-changing glass 3 , an insulating glass 4 and an inner glass 5 are packaged and fixed in the encapsulation frame 1 . Wherein, the outer layer of glass 2 and the inner layer of glass 5 are tempered glass. The color-changing glass 3 is photochromic glass or electrochromic glass, through the color-changing glass 3, the light intensity irradiated into the room through the glass curtain wall can be adjusted. If the color-changing glass 3 is photochromic glass, when the outdoor light is strong, the color of the color-changing glass 3 becomes darker, thereby preventing stronger light from entering the room.

[0034] Such as Figure 4 and 5 As shown, the packaging frame 1 is a rectangular structure, and the inner wall of the packaging frame 1 is welded with a limiting frame 101 , or the limiting frame 101 and the pack...

Embodiment 2

[0048] On the basis of Example 1, as Figure 6 As shown, a number of blind holes 108 or strip-shaped sinking grooves are evenly distributed on the inner wall of the limiting frame body 101; the blind holes 108 or strip-shaped sinking grooves are used to install desiccant, and the color-changing glass 3 and the outer layer are realized by the desiccant. The inside of the cavity formed between the glass 2 is dried to avoid the formation of water vapor on the side of the outer glass 2 or the color-changing glass 3 .

[0049] After the desiccant is put into the blind hole 108 or the bar-shaped sinker, the blind hole 108 or the bar-shaped sinker can be blocked with an air-permeable tape, so as to prevent the desiccant from being exposed or falling into the space between the color-changing glass 3 and the outer glass 2 What happens inside the cavity formed.

Embodiment 3

[0051] On the basis of Embodiment 1 or Embodiment 2, the side where the limiting frame 101 is attached to the outer glass 2 is covered with a gasket. At the same time, the side where the outer fixed frame 107 is attached to the outer glass 2 is covered with a sealing strip. The sealing effect between the outer glass 2 and the encapsulation frame 1 can be improved by arranging the gasket and the sealing strip, so as to prevent outdoor rainwater or water vapor and dust from entering the cavity formed between the color-changing glass 3 and the outer glass 2 , thus effectively improving the internal cleanliness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com