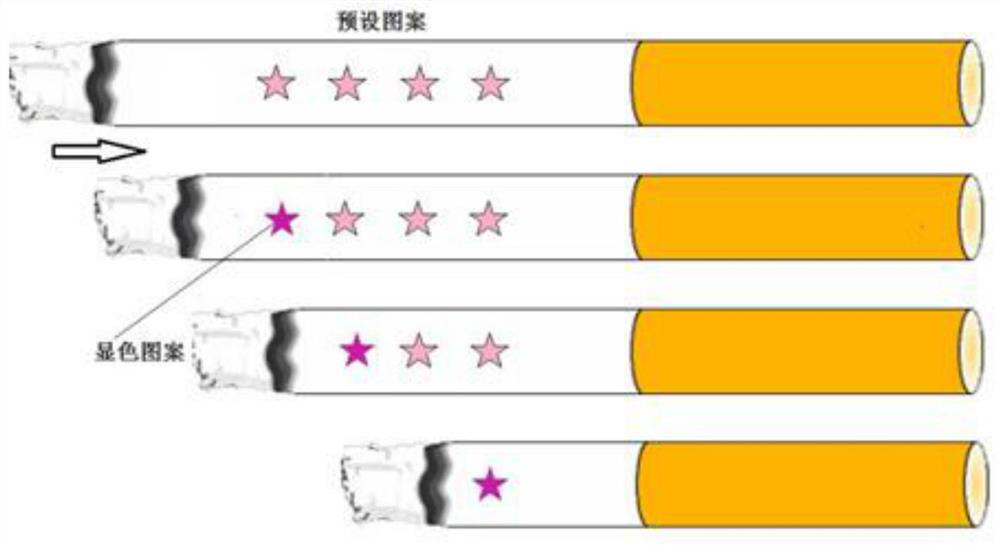

Thermochromic material, preparation method thereof and application of thermochromic material in cigarette paper

A temperature-induced discoloration and cigarette paper technology, applied in the field of tobacco, can solve the problems of unfavorable temperature-induced discoloration, long time, unfavorable temperature-induced discoloration, etc., to achieve obvious thermochromism effect, fast temperature-induced discoloration, and protective effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Preparation of temperature-discolored materials of the system of hollow-boric acid in the hollow mesh silica, and the preparation of coated roll paper. Proceed as follows:

[0046] 1. Synthesis template polystyrene microspheres (PS microspheres).

[0047] 1.0g Polyvinylpyrrolidone K-30 (PVP), ultrasonic dispersion at 100.0 ml of anhydrous ethanol and 10.0 ml of deionized water; mechanical stirring (250 rpm) and bubbles 10 min in nitrogen; 0.158 g of azo 2 Isobutyronitrile (AIBN), dissolved in 11.0 mL (10.0 g) styrene, then added in the above-mentioned alcohol aqueous solution; after 10 min, the temperature was raised to 70 ° C, and after 24 h, it was cold to room temperature, The product was centrifuged, and three times were washed three times with ethanol, and the dried gas drying tank was placed in a gas drying tank; ie the PS microspheres.

[0048] 2, synthetic PS @ SiO 2 Microspheres.

[0049] Two reaction solutions were first formulated. The reaction liquid ...

Embodiment 2

[0064] Example 2: Preparation of a temperature-discolored material of a system of amino modified hollow diaphragm silica loaded phenol red-boric acid, and the preparation of coated roll paper. Proceed as follows:

[0065] Step 1-3 as in Example 1.

[0066] 4. Preparation of the amino-modified hollow mesoporous silica.

[0067] 1.0g of hollow mesoporous silica H-SIO 2 In the single mouth round bottom flask, 50.0 ml of toluene was added, and the ultrasonic dispersion was dissociated; 2.0 ml of 3-aminopropyltriethoxysilane (APTES) was added to 115 ° C with a magnetic stirring; and reflux 10 h. The product was then centrifugally isolated, washed 3 times with 75% ethanol, and then dried in a 50 ° C blast drying box, i.e., the amino-modified hollow mesoperin silica (H-SiO) 2 -NH 2 ),spare.

[0068] 5, cresol red - boric acid preparation.

[0069] Step 4 of Example 1.

[0070] 6, cresol red-borate load in H-SiO 2 -NH 2 superior.

[0071] Trying step 4 H-SIO 2 -NH 2 The product 500 mg ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com