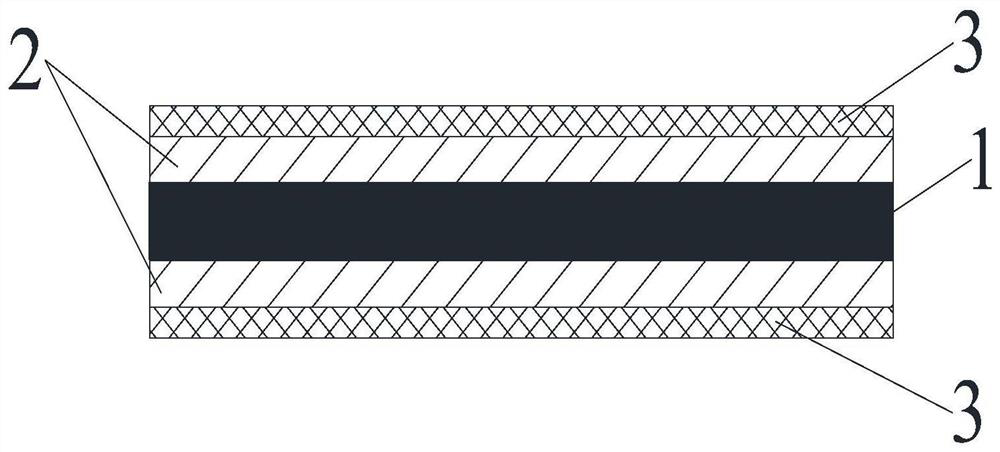

Phase-change heat conduction slurry, heat conduction diaphragm and lithium ion battery

A technology of phase change heat conduction and phase change materials, which is applied in the fields of phase change heat conduction paste, battery diaphragm, heat conduction diaphragm and lithium-ion battery. It can solve the problems of poor thermal conductivity, reduce interface impedance, reduce heat production, and improve thermal safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a phase-change heat-conducting slurry, which includes expanded graphite composite paraffin phase-change materials, a binder and a solvent; the solid content of the phase-change heat-conducting slurry is 50 wt%.

[0061] The mass ratio of described expanded graphite composite paraffin phase-change material and binder is 90:10;

[0062] The binder is polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP, 5130); the solvent is water;

[0063] The expanded graphite composite paraffin wax phase change material is prepared by the following method, and the method includes the following steps: mixing expanded graphite and paraffin (melting point 58° C.) according to a mass ratio of 1:1.1, and stirring and blending at 75° C. for 70 minutes to obtain The expanded graphite composite paraffin phase change material;

[0064] The expanded graphite is obtained from expandable graphite (average particle size 50 mesh, expansion rate 200mL / g) through s...

Embodiment 2

[0067] This embodiment provides a phase-change heat-conducting paste, which is the same as that of Embodiment 1 except that the solid content of the phase-change heat-conducting paste is 30 wt%.

Embodiment 3

[0069] This embodiment provides a phase-change heat-conducting paste, which is the same as that of Embodiment 1 except that the solid content of the phase-change heat-conducting paste is 75 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com