Gel polymer for bionic while-drilling pressure-bearing plugging drilling fluid

A technology of gel polymer and plugging agent, which is applied in the field of oil and gas well drilling, which can solve the problems of poor adhesion, poor adaptability of leakage layer size, non-deformability, etc., so as to improve the success rate and avoid the effect of flushing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

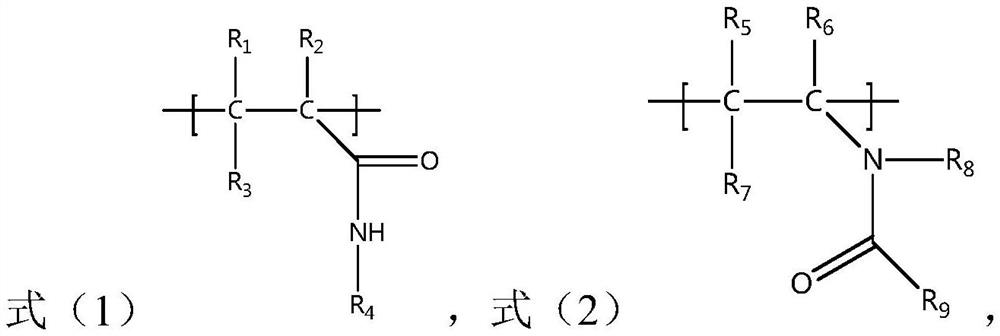

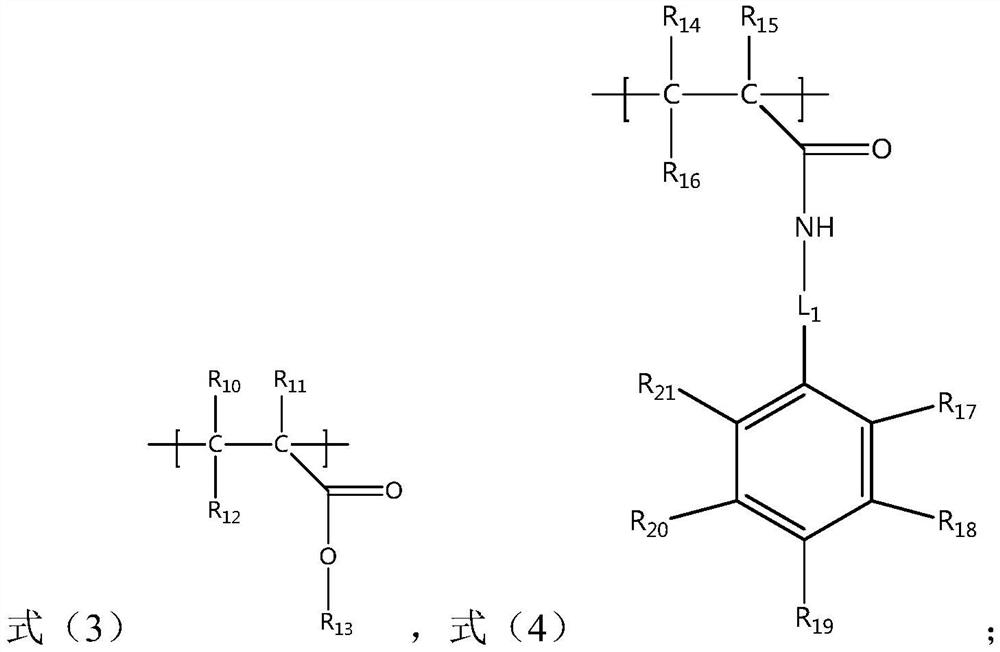

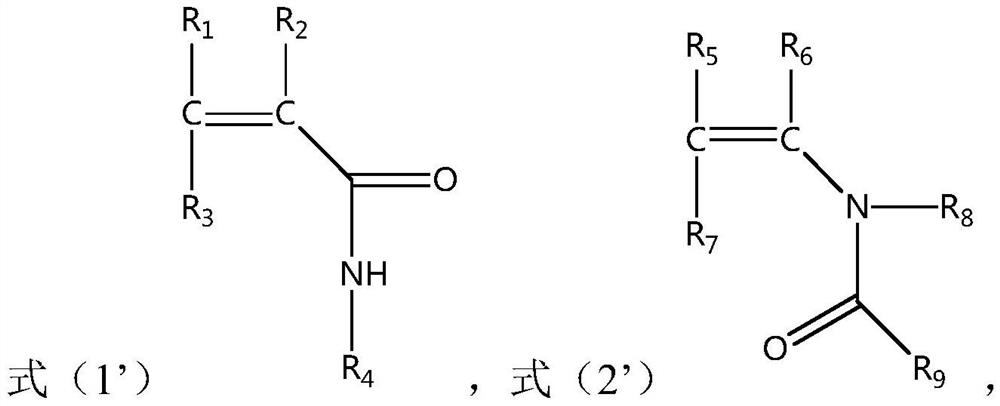

[0029] The second aspect of the present invention provides a method for preparing a gel polymer suitable for a lost circulation agent, the method comprising: in an aqueous solvent, in the presence of an initiator, an amide monomer, a carboxylic acid monomer and a benzene Diphenolic monomers carry out solution polymerization reaction, wherein, the amide monomers are selected from one or more of the monomers shown in formula (1') and formula (2'); the carboxylic acid monomers The monomer is selected from one or more of the monomers shown in formula (3'); the diphenol monomer is selected from one or more of the monomers shown in formula (4');

[0030]

[0031] Among them, R 1 -R 3 , R 5 -R 7 , R 10 -R 12 and R 14 -R 16 each independently selected from H and C1-C6 alkyl; R 4 Alkyl selected from H, C1-C8 or -L 2 -SOOM,L 2 An alkylene group selected from C1-C6, M is H or an alkali metal element; R 8 and R 9 each independently selected from H and C1-C6 alkyl, or R 8 a...

Embodiment 1

[0047] This example is used to illustrate the gel polymer of the present invention and its preparation method.

[0048] Add 3 g of acrylamide monomer into 100 ml of distilled water, then add 3 g of acrylic acid monomer, and finally add 2 g of 3-methacrylamide dopamine monomer. Stir at 30°C (stirring rate 150r / min) until dissolved. Introduce high-purity nitrogen to remove oxygen in the system, and nitrogen inflow time is 30min. After that, the initiator azobisisobutyronitrile (mass addition: 0.1% by weight, relative to the total weight of the monomers) was added dropwise. Gradually raise the temperature to 55°C and react for 5h. The polymer water-absorbing gel product can be produced. Pour the product into a beaker filled with 200ml of distilled water, stir for 2-5 minutes, and then filter to remove unreacted monomers. The washed product was dried in an oven at 75 °C for 36 h until constant weight. The dried product is pulverized by a pulverizer and screened with an analyt...

Embodiment 2

[0050] This example is used to illustrate the gel polymer of the present invention and its preparation method.

[0051] In 100ml of distilled water, add 4g total amount of acrylamide and N-vinyl caprolactam monomer (the molar ratio of acrylamide and N-vinyl caprolactam is 1:1), then add 3g total amount of acrylic acid and methacrylic acid monomer (the molar ratio of acrylic acid and methacrylic acid is 1:1), finally add 3-methacrylamido dopamine and N-[2-(3,4-dihydroxyphenyl) ethyl]-2 - Acrylamide monomer (3-methacrylamido dopamine and N-[2-(3,4-dihydroxyphenyl)ethyl]-2-acrylamide in a molar ratio of 1:1). Stir at 30°C (stirring rate 170r / min) until dissolved. Introduce high-purity nitrogen to remove oxygen in the system, and nitrogen inflow time is 30min. Then, the initiator azobisisobutyronitrile (mass addition: 0.25% by weight, relative to the total weight of the monomers) was added dropwise. Gradually raise the temperature to 60°C and react for 5.5h. The polymer water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com