Bridge engineering safety construction platform

A technology for bridge engineering and construction platform, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of inconvenient change of working position, the inability of safe construction platform to be sent to the lower part of the bridge independently, etc., to achieve the effect of protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

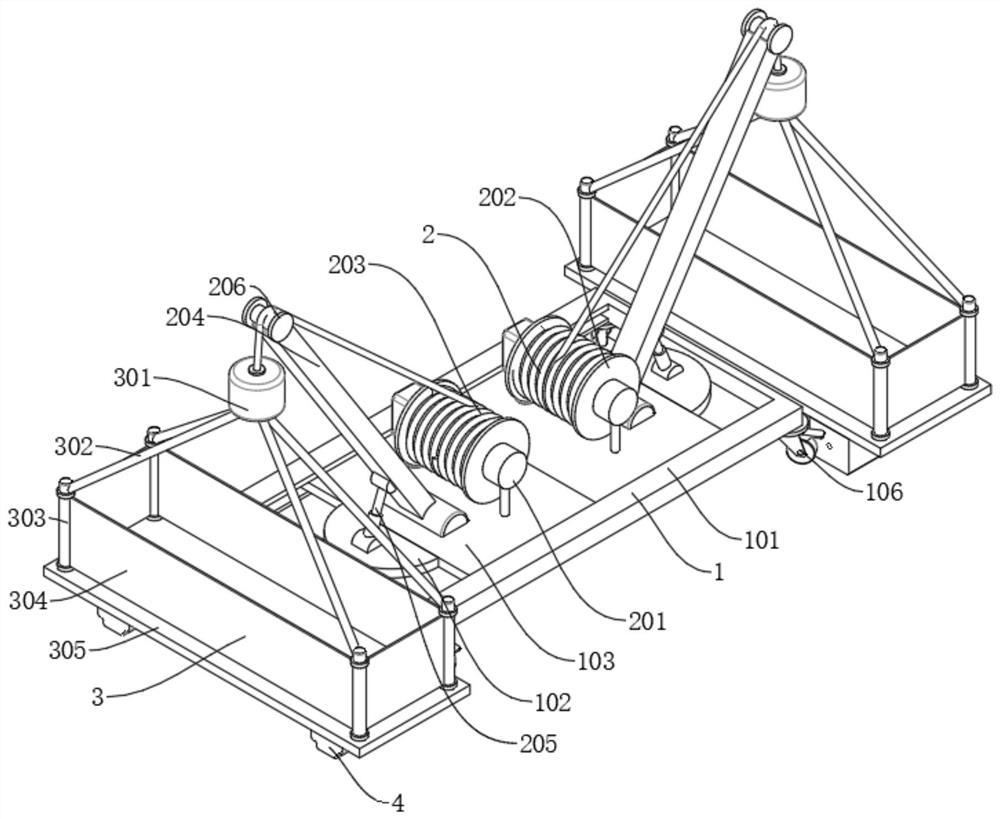

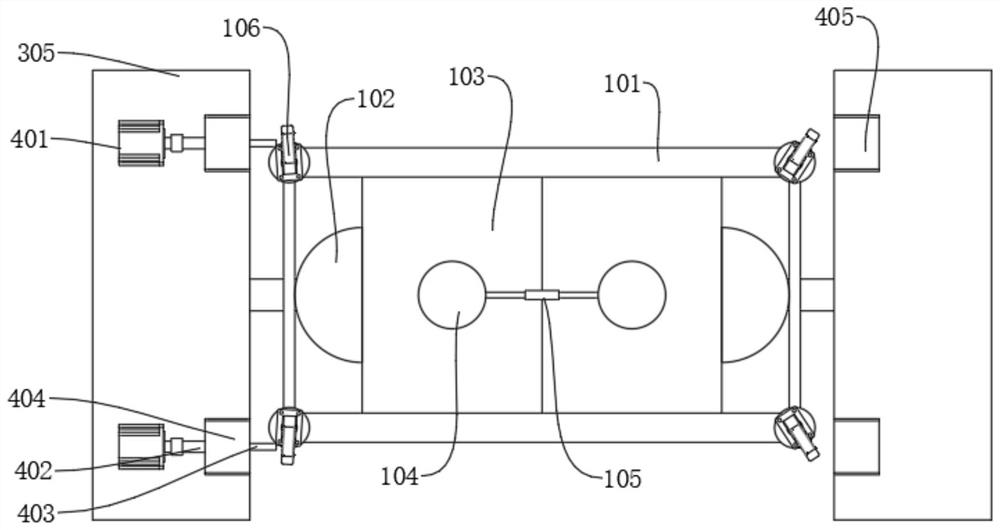

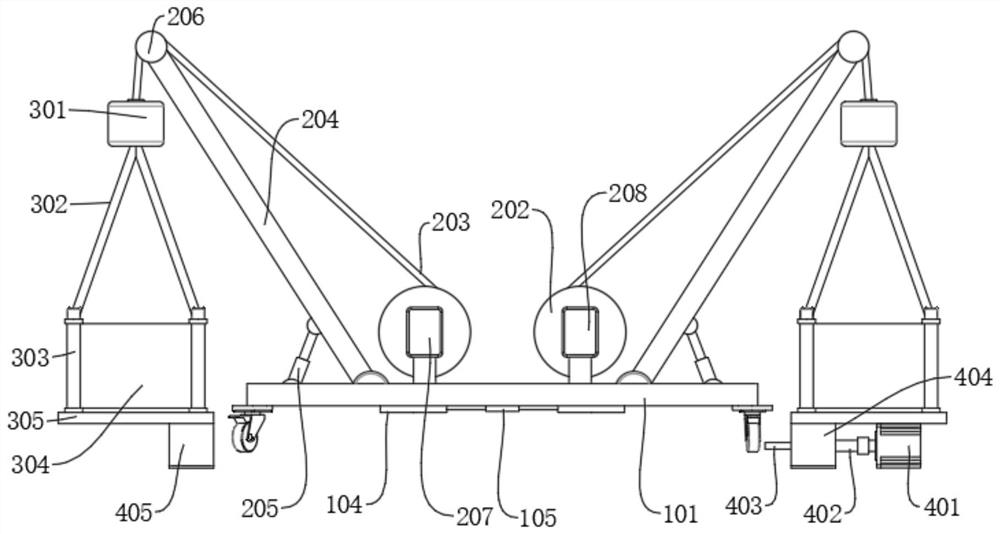

[0028] see Figure 1-Figure 4 , the present invention provides a bridge engineering safety construction platform: comprising a moving mechanism 1, a lifting mechanism 2, and a standing mechanism 3, a lifting mechanism 2 is installed on the upper part of the moving mechanism 1, and a standing mechanism 3 is installed at one end of the lifting mechanism 2, It also includes an adjustment mechanism 4 capable of changing the distance between the standing mechanisms 3. The adjustment mechanism 4 includes a second motor 401, a telescopic hydraulic rod 402, a threaded screw 403, a positioning block 404, a movable thread block 405, and one side of the second motor 401. A telescopic hydraulic rod 402 is connected through a coupling, the telescopic end of the telescopic hydraulic rod 402 is equipped with a threaded screw 403, the outside of the threaded screw 403 is provided with a positioning block 404, and one side of the positioning block 404 is provided with a movable threaded block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com