Transverse adjustment method for spraying process of water mist cooling section of continuous annealing unit by taking control plate shape as target

A technology of water mist cooling and horizontal adjustment, applied in the field of metallurgy, can solve the problems of poor shape control, failure to detect, and no configuration of automatic control functions for shape, etc., and achieve broad application prospects and improve the effect of shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

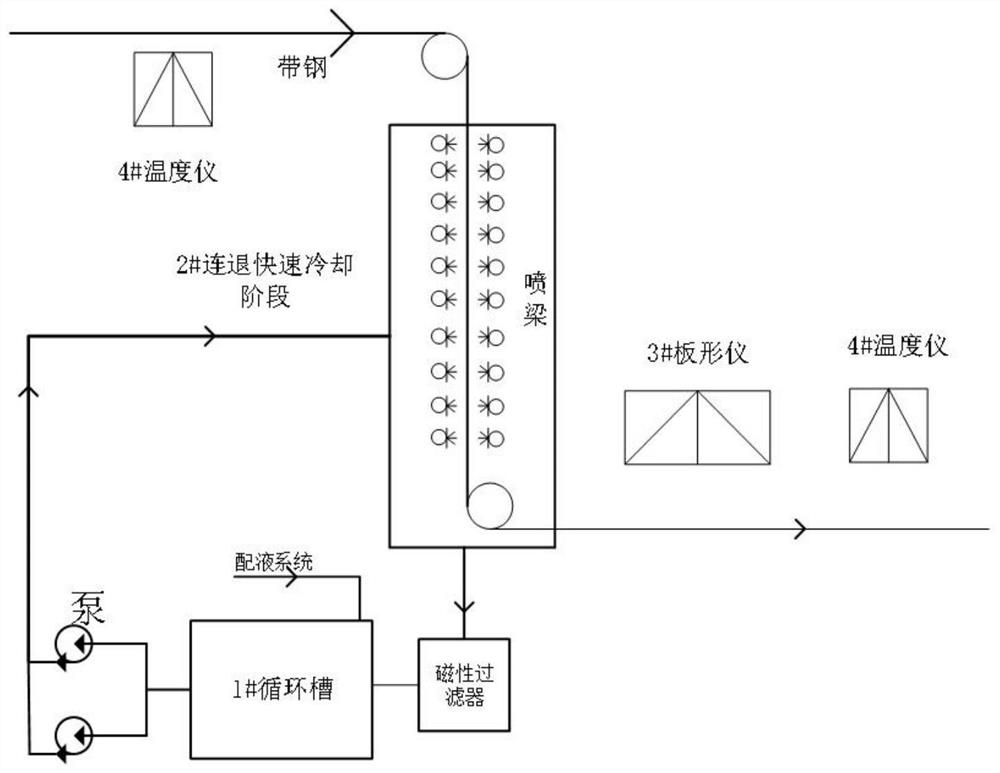

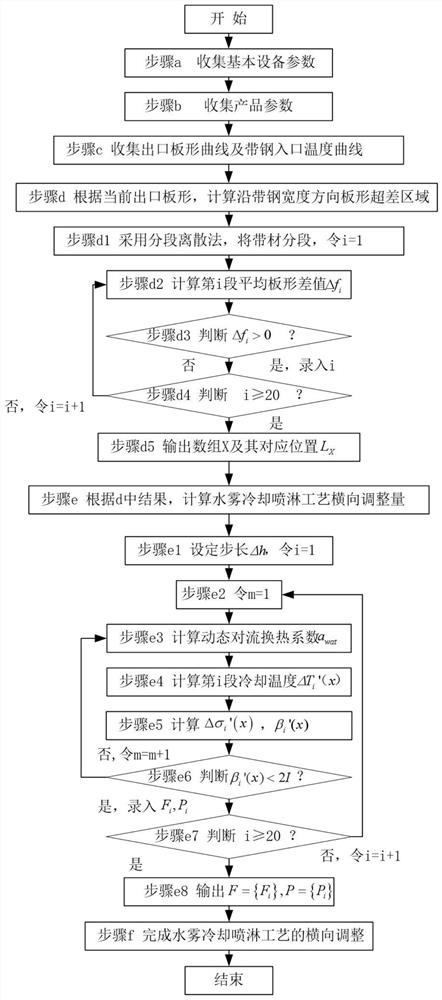

[0033] In order to illustrate the application process of the related technology described in the present invention, now taking the water mist cooling system of a certain continuous cooling unit as an example, the calculation process of the lateral adjustment of the spray process in the water mist cooling section is introduced in detail as follows, as follows: image 3 , including the following computer-executed steps:

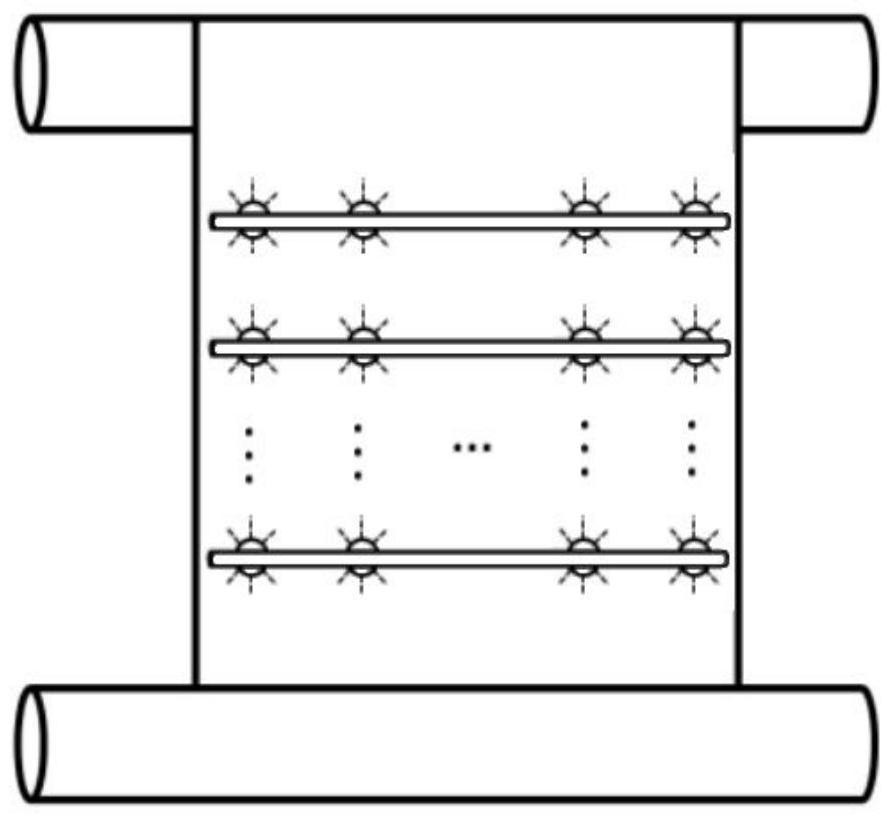

[0034] (a) Collect the basic equipment characteristic parameters of the three-cold rolling continuous annealing unit, including: the minimum flow rate F of the nozzle 0 =0L / min, flow characteristic coefficient K=80, strip running speed V=150m / min, nozzle effective area S=0.0132m 2 , the number of longitudinal nozzles n y =40, cooling longitudinal length L=11727mm, water temperature T wat = 20°C;

[0035] (b) Collect the product parameters of typical specification steel types in the annealing process, including: strip width B=1080mm, strip elastic modulus E=2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com