Steel ball quenching device

A technology of quenching device and steel ball, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., and can solve the problems of environmental pollution, prominent dust phenomenon, and temperature conditions that cannot be guaranteed to be stable and uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

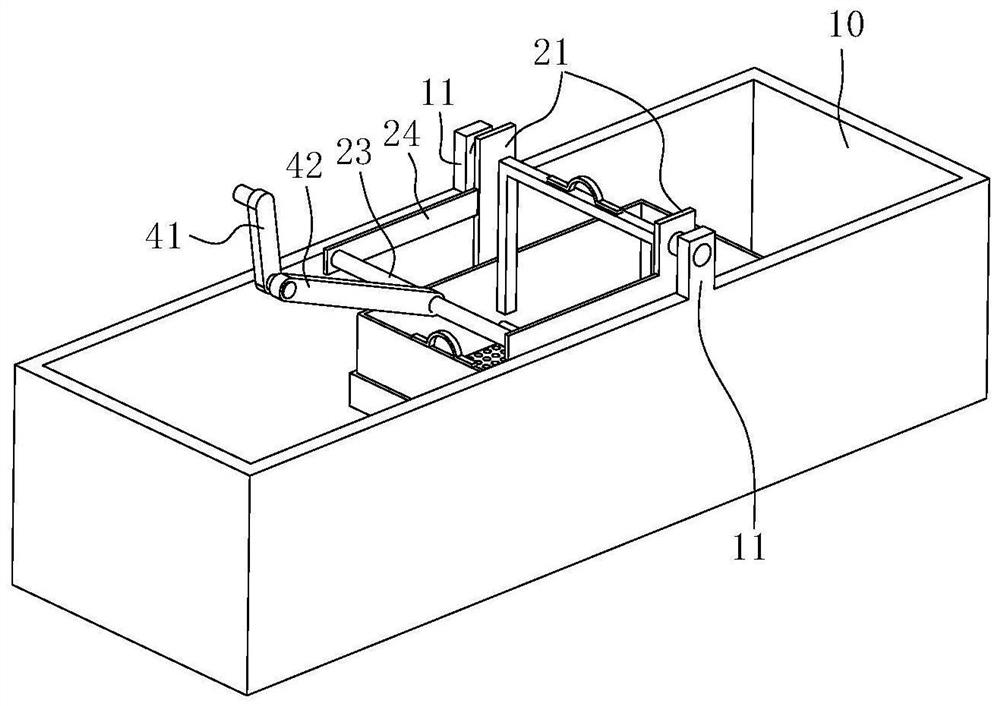

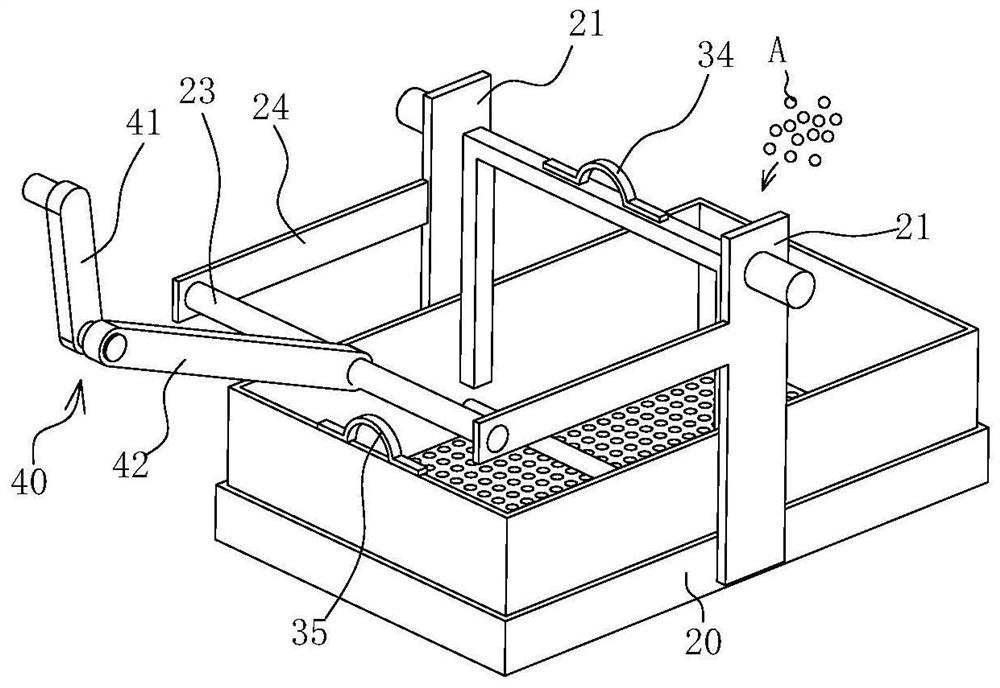

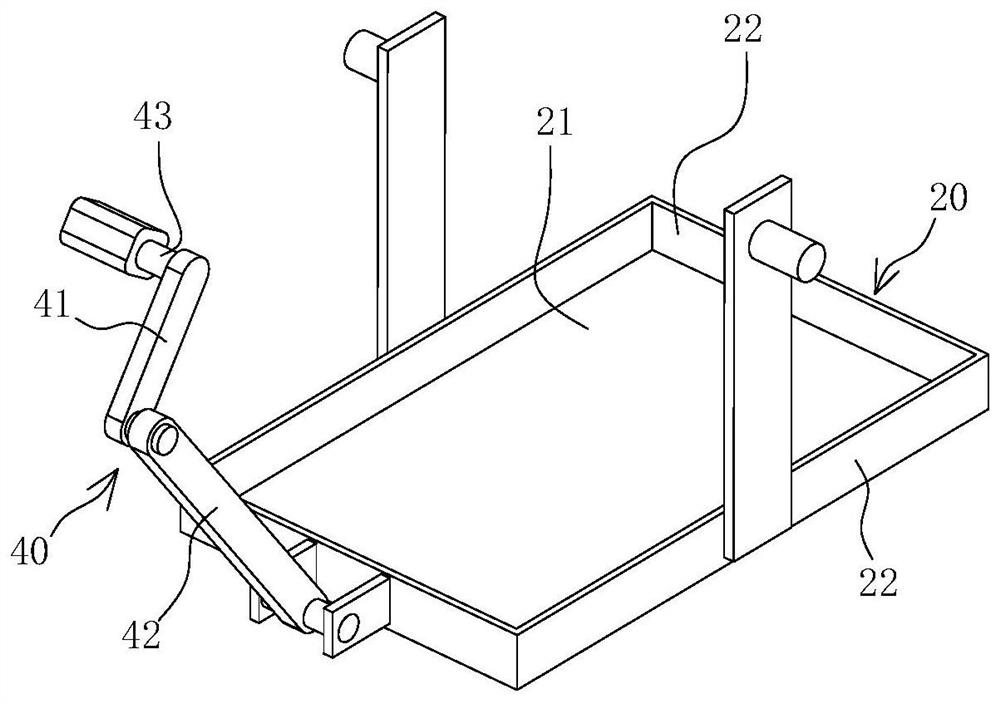

[0014] Such as figure 1 As shown, the steel ball quenching device includes a tank 10 filled with a cooling medium, a bracket 20 immersed in the cooling medium has an upwardly extending boom 21, the upper end of the boom 21 is hinged with the bracket 11, and the bracket 20 is connected to the drive mechanism. Connected and the drive mechanism drives the bracket 20 to perform a reciprocating swing around the hinged shaft core. A steel ball holding container is arranged on the bracket 20, and a liquid-permeable hole is arranged on the steel ball holding container.

[0015] In the above scheme, the bracket 20 immersed in the cooling medium is hingedly connected to the bracket 11 by means of the boom 21 thereon, the bracket 20 has the characteristic of rotating around the hinge axis, and performs a swinging action under the drive of the driving mechanism. During the swinging process of the bracket 20, on the one hand, the cooling agent in the tank 10 is stirred to make the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com