Auxiliary scrap collecting device of steel machining equipment

A processing equipment and collection device technology, which is applied in the field of steel and aluminum, can solve the problems of steel waste collection, steel waste scattered on the surface of the equipment, and the equipment cannot be kept clean all the time, so as to facilitate recycling and save storage space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

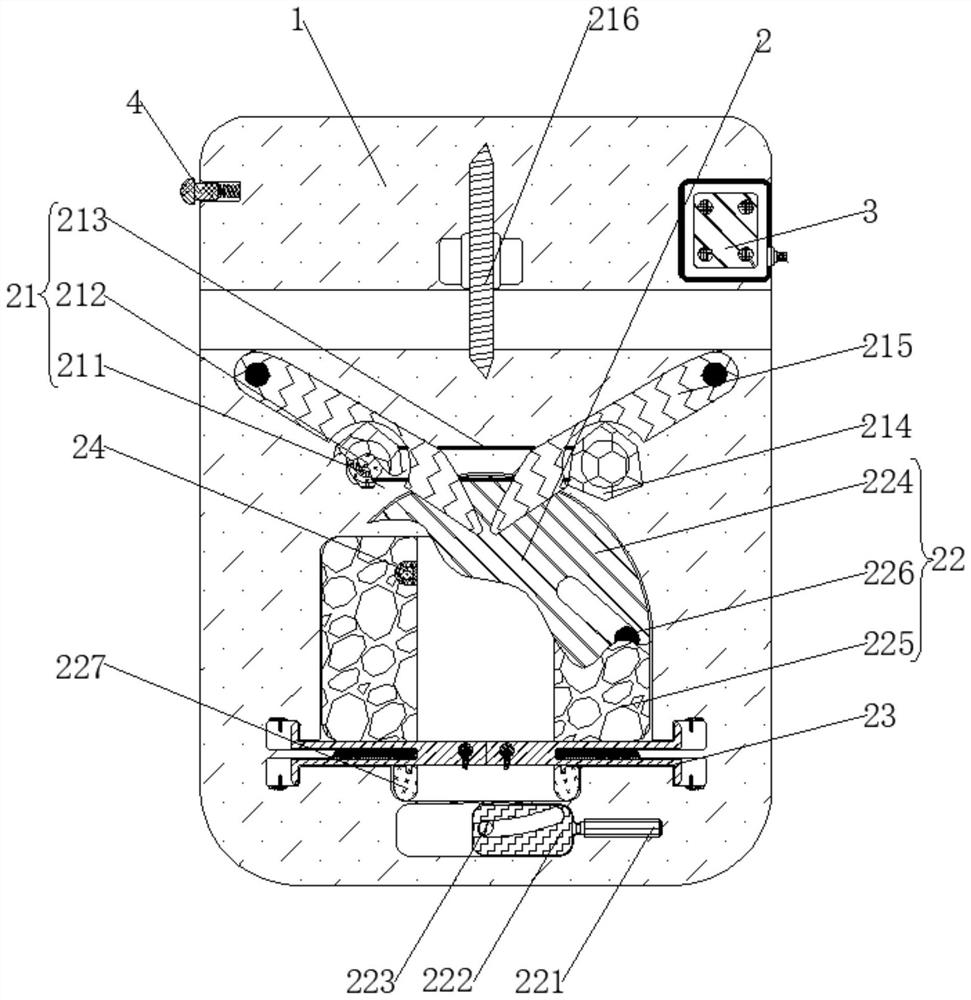

[0026] see figure 1 , an auxiliary waste collection device for steel processing equipment, comprising a casing 1, a collection and compression mechanism 2 is arranged inside the casing 1, and the collection and compression mechanism 2 includes a vibrating assembly 21, a compression assembly 22, a discharge assembly 23, a trigger assembly 24, and the casing 1 is provided with a vibrating assembly 21 for collecting waste. The vibrating assembly 21 includes a motor 211, a transmission wheel 212, a transmission belt 213, a hexagonal block 214, a vibrating plate 215, and a cutting wheel 216. The inside of the housing 1 is fixedly connected with a motor 211. The drive wheel 212 is fixedly connected to the outside of the motor 211, the drive belt 213 is drive connected to the outside of the drive wheel 212, the hexagonal block 214 is fixedly connected to the outside of the drive wheel 212, and the vibrating plate 215 is rotatably connected to the inside of the housing 1. The vibrating...

Embodiment 2

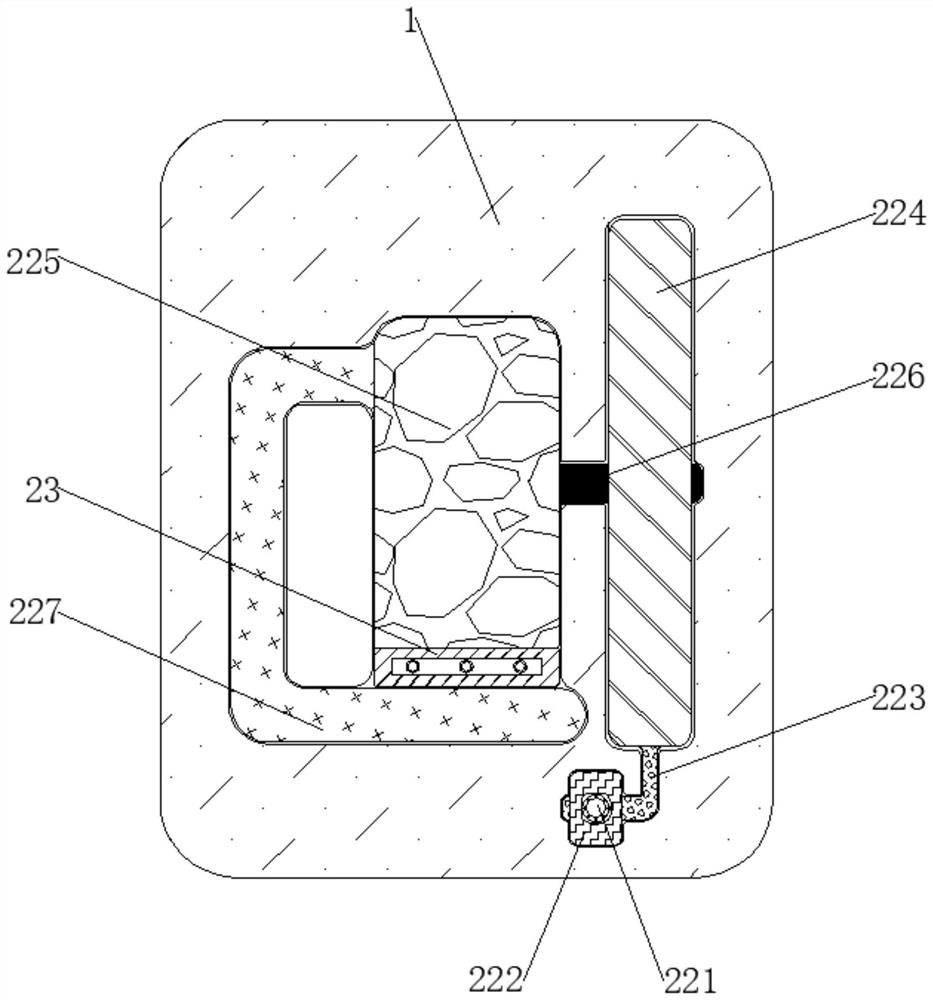

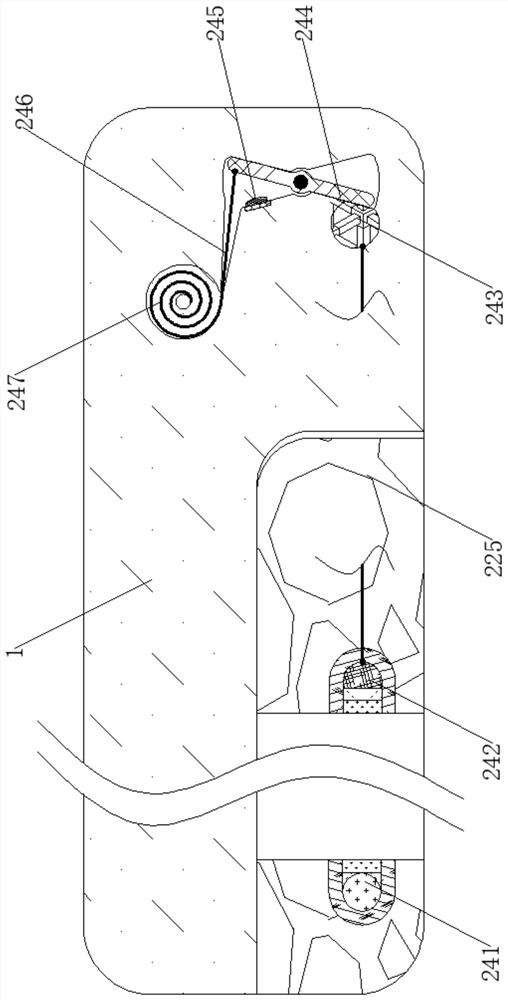

[0029] see Figure 2-4 , an auxiliary waste collection device for steel processing equipment, comprising a casing 1, a collection and compression mechanism 2 is arranged inside the casing 1, and the collection and compression mechanism 2 includes a vibrating assembly 21, a compression assembly 22, a discharge assembly 23, a trigger assembly 24, and the casing 1 is provided with a vibrating assembly 21 for collecting waste, and the interior of the housing 1 is provided with a compression assembly 22 for compressing waste. Compression plate 225, connecting column 226, curved rod 227, the inside of shell 1 is fixedly connected with electric telescopic rod 221, and sliding rod 222 is fixedly connected with the outside of electric telescopic rod 221, and connecting rod 223 is movably connected with the outside of sliding rod 222, rotates The ring 224 is fixedly connected to the outside of the connecting rod 223, the compression plate 225 is slidably connected to the inside of the s...

Embodiment 3

[0033] see Figure 1-4 , an auxiliary waste collection device for steel processing equipment, comprising a casing 1, a collection and compression mechanism 2 is arranged inside the casing 1, and the collection and compression mechanism 2 includes a vibrating assembly 21, a compression assembly 22, a discharge assembly 23, a trigger assembly 24, and the casing 1 is provided with a vibrating assembly 21 for collecting waste. The vibrating assembly 21 includes a motor 211, a transmission wheel 212, a transmission belt 213, a hexagonal block 214, a vibrating plate 215, and a cutting wheel 216. The inside of the housing 1 is fixedly connected with a motor 211. The drive wheel 212 is fixedly connected to the outside of the motor 211, the drive belt 213 is drive connected to the outside of the drive wheel 212, the hexagonal block 214 is fixedly connected to the outside of the drive wheel 212, and the vibrating plate 215 is rotatably connected to the inside of the housing 1. The vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com