Process for recovering iron resources from waste dump

A technology for dumping and recycling iron, which is applied in the direction of solid separation, etc., can solve the problems of low iron resource content and difficulty in utilization, and achieve the effects of fine particle size, reduced operating costs, and good dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

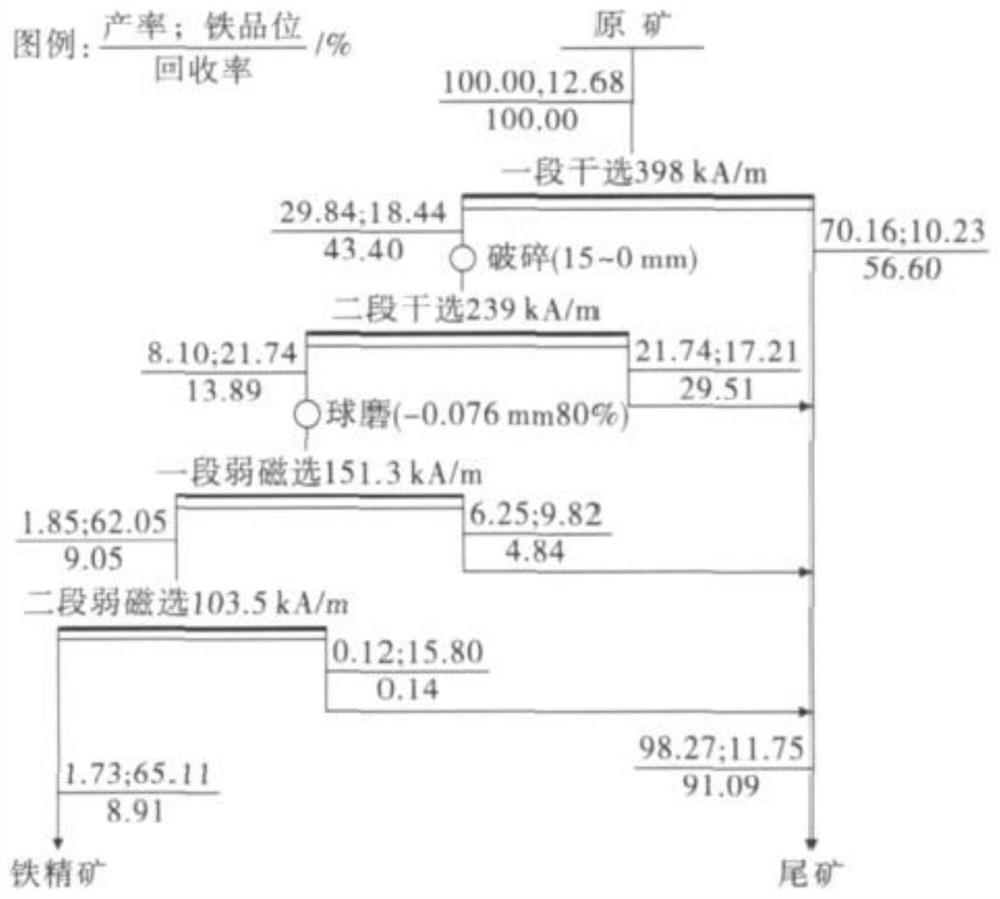

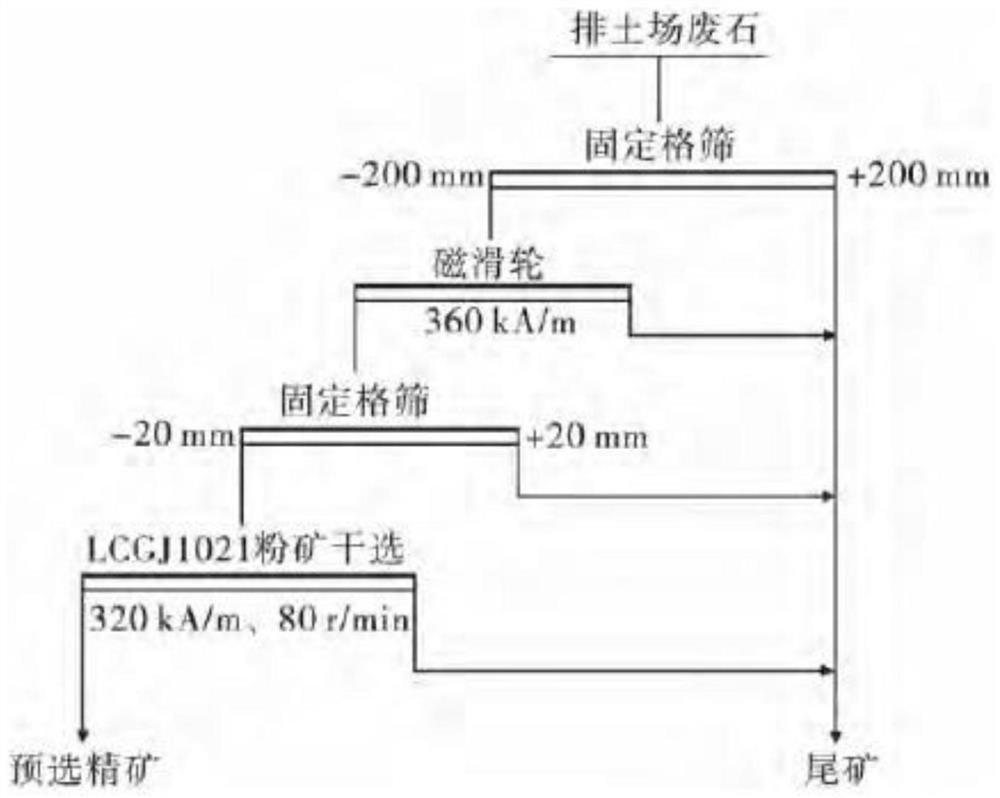

[0039] From the No. 3 dump in Baiyun Obo, samples transported by car and samples transported by tape were collected at a ratio of 1:1 and mixed for dry pre-selection. The jaw crusher is used for crushing, and the raw ore is crushed to obtain a coarsely crushed product with a particle size of -300mm. The dry separation machine with a field strength of 199.04kA / m is used to dry the coarsely crushed product to obtain a total iron grade of 14.15%. Dry beneficiation concentrate K1; K1 is crushed to obtain a medium crushed product with a particle size of -60mm. The dry beneficiation machine with a field strength of 278.66kA / m is used to dry the medium crushed product to obtain a dry beneficiation concentrate with a total iron grade of 15.51%. Dry beneficiation concentrate K2; K2 is crushed to obtain finely crushed products with a particle size of -12mm, and the finely crushed products are dry separated by a dry separator with a field strength of 278.66kA / m to obtain a dry beneficiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com