Sludge biochar loaded magnesium-iron oxide composite material for removing lead and cadmium in water as well as preparation method and application thereof

A composite material, biochar technology, applied in water pollutants, chemical instruments and methods, water/sludge/sewage treatment, etc. problem, to achieve the effect of superior physical and chemical properties, strong adsorption and removal capacity, and high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

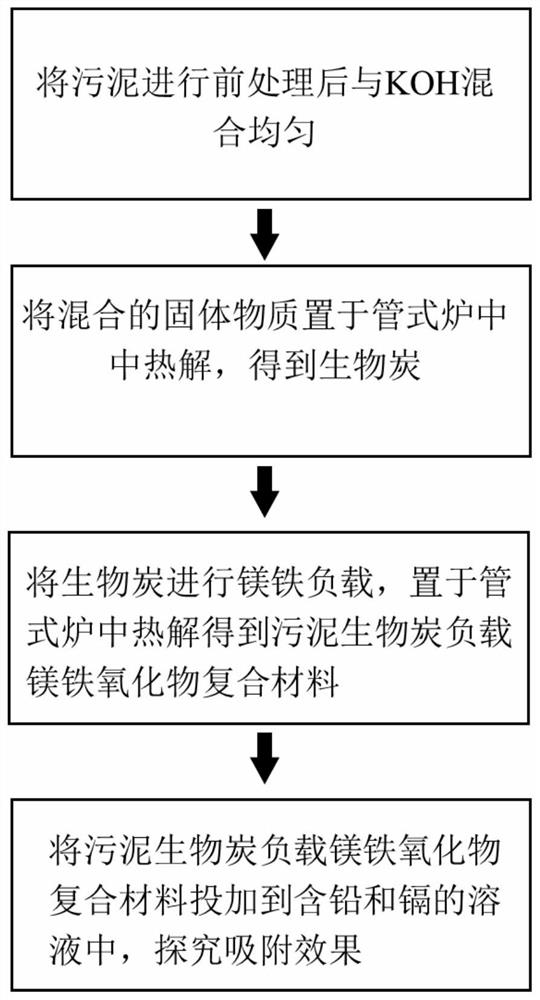

[0034] A method for preparing sludge biochar-loaded magnesium-iron oxide composite materials for efficient removal of lead and cadmium in water, the flow diagram is as follows figure 1 shown, including the following steps:

[0035] (1) Preparation of sludge biochar: Dry the dehydrated municipal sludge at 105°C for 24 hours, save it for later use; weigh 5g of sludge and mix it with 10ml of potassium hydroxide solution containing 3.33g, let it stand for 6 hours Dry it in an oven at 105°C, and grind it through a 100-mesh sieve. The resulting substance was placed in a tube furnace, under nitrogen protection conditions (nitrogen flow rate 80mL min -1 ), at a heating rate of 6.24℃·min -1 Carbonize at 630°C for 45min at a certain temperature, then cool to room temperature under nitrogen protection; then take out the sample, wash it several times with distilled water to make the filtrate neutral, dry it at 105°C, crush it through a 100-mesh sieve, and obtain sludge bio Charcoal, sa...

Embodiment 2

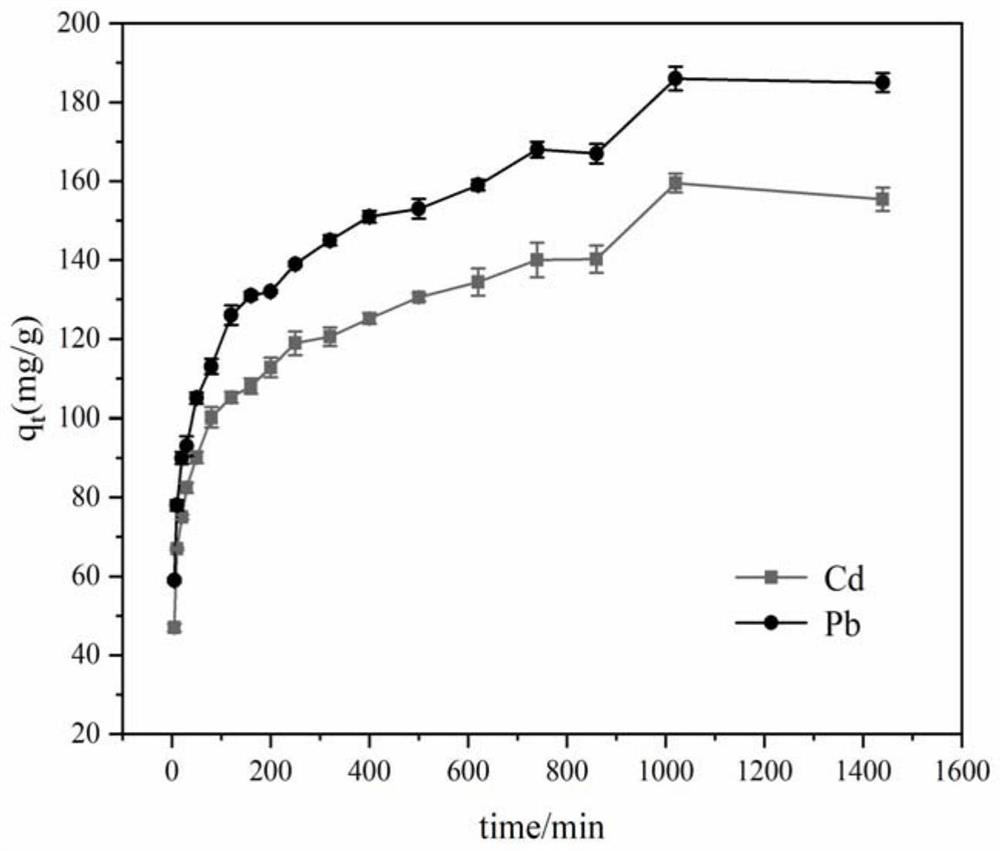

[0038] A dose of 0.05g of the obtained sludge biochar-loaded magnesium-iron oxide composite material in Example 1 was added to the cadmium solution and the lead solution of 100ml 100mg / L respectively, and the pH was adjusted with 0.1mol / L of HCl and NaOH solution If it is 5, place it at 25°C and shake it at a constant temperature, take samples at the set time (5-1440min), pass through a 0.45μm water filter membrane, measure the remaining concentration under the flame atomic adsorption spectrophotometer, and calculate the adsorption amount.

[0039] Depend on figure 2 It can be seen that the adsorption amount of lead and cadmium by the sludge biochar-loaded magnesium-iron oxide composite material increases with time. At 1440min, the adsorption amount of lead is 185.34mg / g, and the removal rate is 92.67%. The adsorption capacity is 155.42 mg / g, and the removal rate is 77.71%.

Embodiment 3

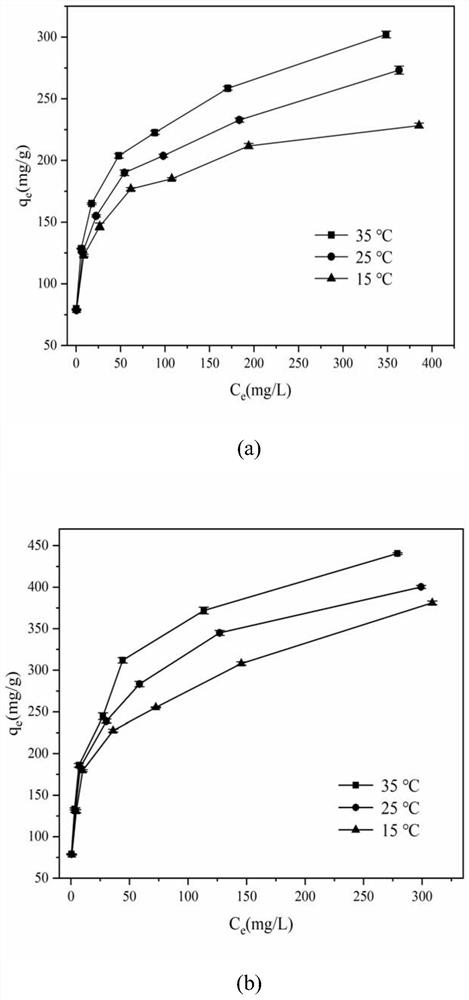

[0041] A dose of 0.05g of the obtained sludge biochar-loaded magnesium-iron oxide composite material in Example 1 was added to the cadmium solution and the lead solution of 100ml 40-500mg / L respectively, and the HCl and NaOH solution of 0.1mol / L Adjust the pH to 5, place at 15-35°C for constant temperature oscillation, take a sample after the reaction is balanced, pass through a 0.45 μm water filter membrane, measure the remaining concentration under the flame atomic adsorption spectrophotometer, and calculate the adsorption amount.

[0042] Depend on image 3 (a) and image 3 (b) It can be seen that when the sludge biochar-supported magnesium-iron oxide composite material is used as the adsorbent, its adsorption capacity for lead and cadmium increases with the increase of the concentration and temperature of lead and cadmium. At 35°C, the maximum adsorption capacity for lead reaches 440.48 mg / g, and the maximum adsorption capacity for cadmium reaches 348.5 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com