Electroluminescent laser display and construction method thereof

An electroluminescent material and luminescent technology, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems of structural compatibility and complex preparation technology, and achieve easy-to-mix laser output, excellent material compatibility, and excellent flow performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

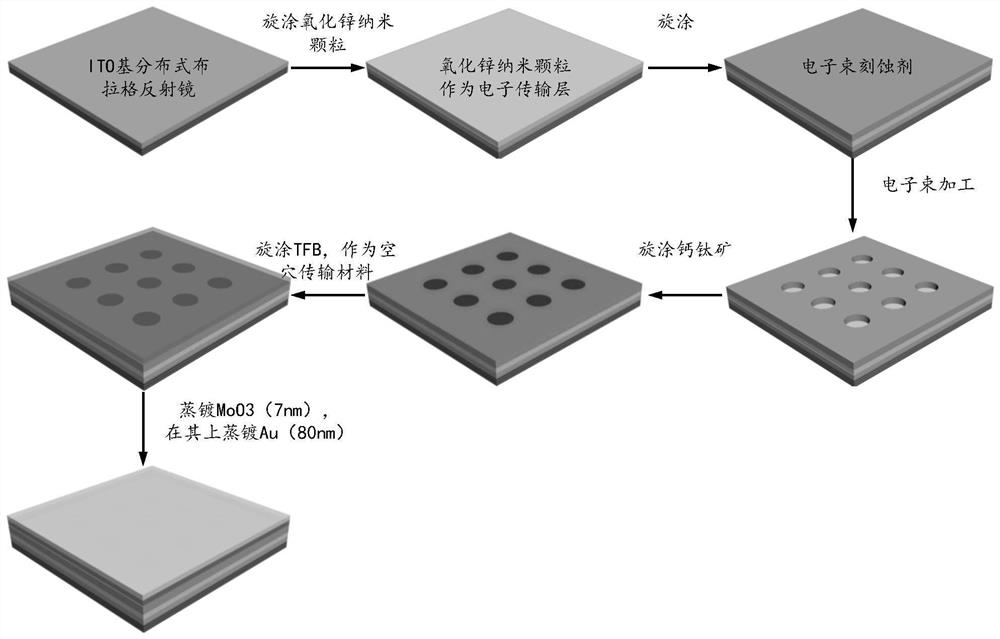

[0080] The electroluminescence laser display panel, the panel including a periodically arranged pixel array, the pixel array electroluminescence laser display panel includes a polymer micromotoischarge as a blank pixel, and an electroluminated micromaine in a spin-coated injection polymer micromotactic structure.

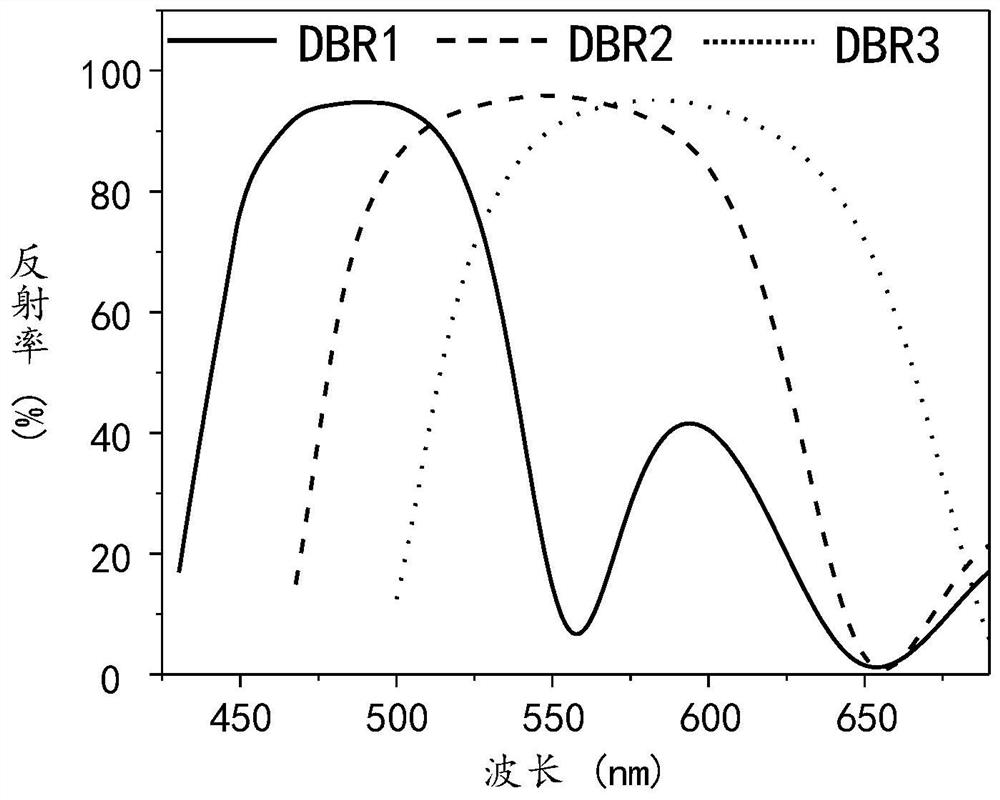

[0081] figure 1 The nature of the distributed Prague mirror used. The ITO-based distributed Prague mirror with high reflectance in the blue zone is DBR1; the ITO-based distributed Prague mirror having high reflectivity in the green spot is DBR2; distribution of ITO based on the red light region The Prague mirror is DBR3. like figure 1 As shown, DBR1, DBR2, and DBR3 have different reflection spectrum, spanning the entire visible region. This facilitates the realization of high-color purity light exits, thereby providing a basis for realizing laser display.

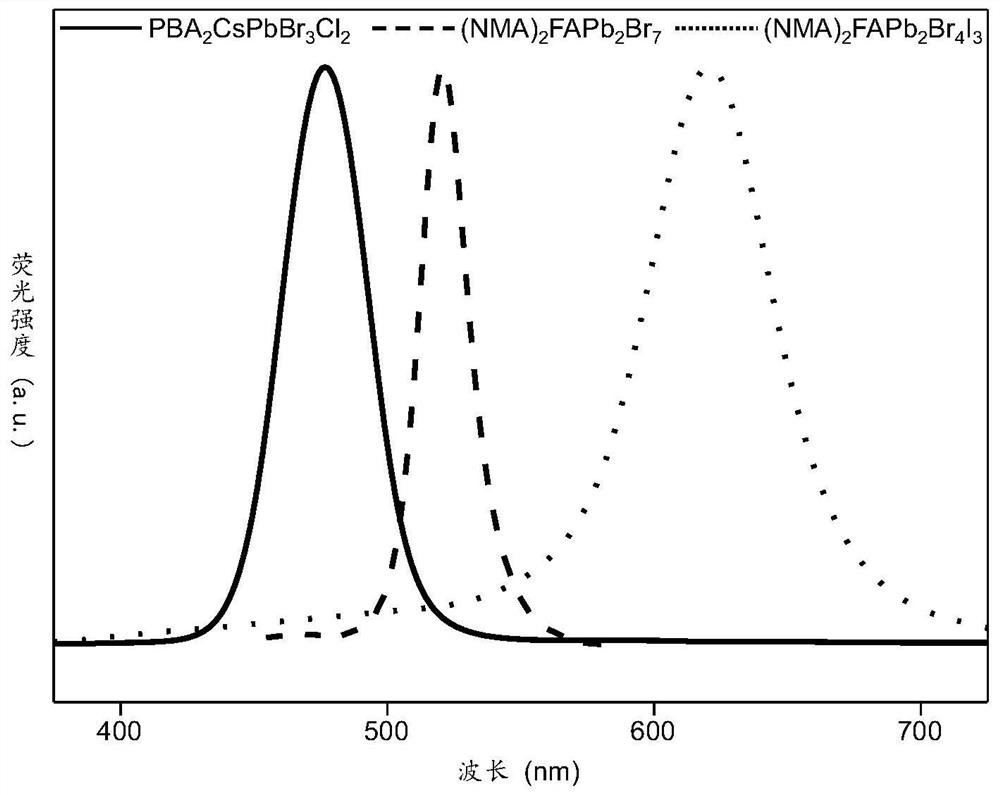

[0082] figure 2 The properties of the perovskite materials used. From figure 2 As can be seen, the fluorescence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com