Inspection robot work adjustment method based on regression analysis algorithm

An inspection robot and regression analysis technology, which is applied in the field of substation inspection, can solve the problem that the work adjustment of the inspection robot does not consider the health of the battery, so as to improve the service life, protect the battery, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

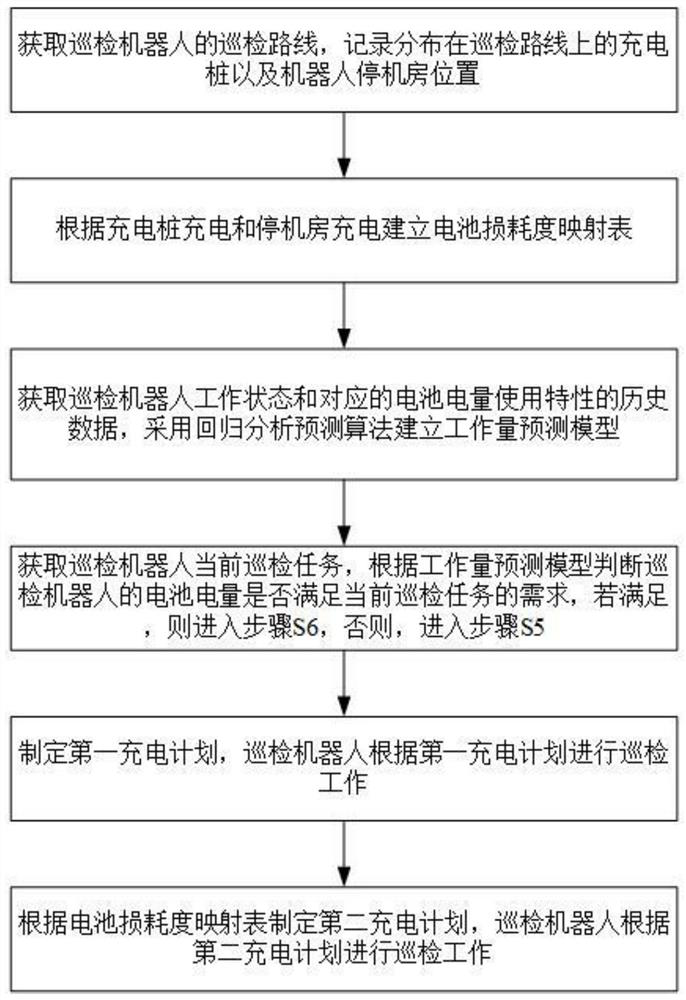

[0039] Embodiment: a kind of inspection robot work adjustment method based on regression analysis algorithm, such as figure 1 shown, including the following steps:

[0040]S1: Obtain the inspection route of the inspection robot, record the charging piles distributed on the inspection route and the location of the robot parking room. The inspection robot is on standby and parked in the parking room. Located in the parking room, there is a deck fixed to the inspection robot in the parking room, and a magnetic bar for charging the inspection robot is set on the deck. The inspection robot is provided with a charging slot that attracts the magnetic bar, and the magnetic bar It is an electromagnetic rod, which is magnetic after being powered on. When the inspection robot receives the inspection command, the magnetic rod is powered off or connected to the reverse current, so that the magnetic rod is no longer charged or mutually repulsed with the charging slot, so that the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com