Sampling tank for storing ambient air samples

An ambient air and sampling tank technology, which is used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, gaseous chemical plating, etc., can solve the problems of sampling failure, easy adsorption, corrosion resistance, etc. , Stable storage performance, ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

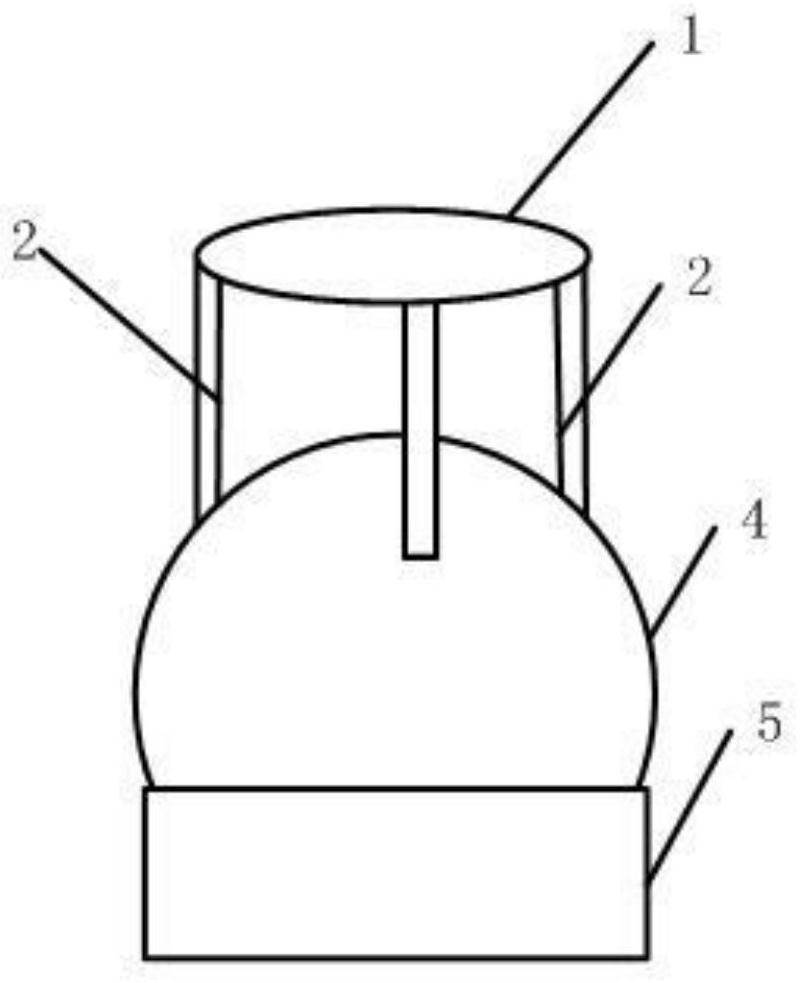

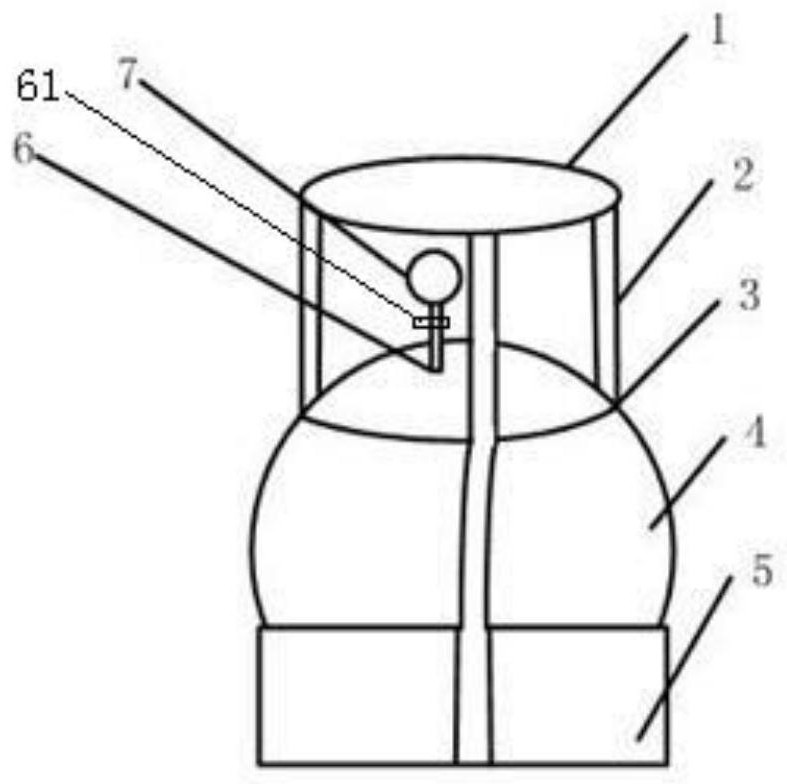

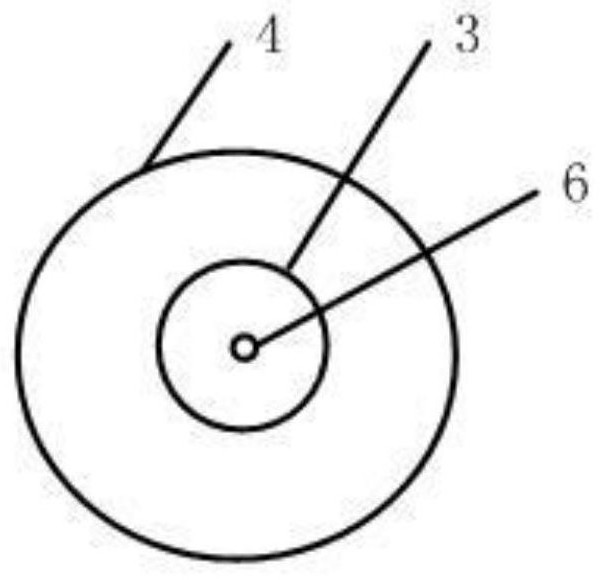

[0029] The air sampling tank provided by the present invention comprises the following structure:

[0030] The sampling tank includes the following structure: a tank body 4 formed by seamless welding of two hemispheres, the upper part of the tank body 4 has a gas port and a valve 6, and the valve 6 is connected with a pressure gauge 7; There is a silicon film layer on the inner wall of the tank body 4, and the coating steps are as follows:

[0031] S1: Vacuumize the sampling tank, fill it with nitrogen, evacuate it, and then fill it with nitrogen, and repeat this cycle until the nitrogen in the sampling tank accounts for more than 99% of the gas in the tank; both vacuuming and nitrogen filling are carried out at room temperature; Keep the pressure at 0.3Mpa during nitrogen treatment;

[0032] S2: Vacuum the sampling tank and fill it with high-temperature hydrogen at 500°C; vacuum again and fill it with high-temperature hydrogen, and repeat this cycle until the hydrogen in the...

Embodiment 1B

[0045] The preparation process of the tank body is the same as in Example 1A, and the coating steps are as follows:

[0046] S1: Vacuumize the sampling tank, fill it with nitrogen, evacuate it, and then fill it with nitrogen, and repeat this cycle until the nitrogen in the sampling tank accounts for more than 99% of the gas in the tank; both vacuuming and nitrogen filling are carried out at room temperature; Keep the pressure at 0.2Mpa during nitrogen treatment;

[0047] S2: Vacuum the sampling tank and fill it with high-temperature hydrogen at 400°C; vacuum again and fill it with high-temperature hydrogen, and repeat this cycle until the hydrogen in the sampling tank accounts for more than 99% of the gas in the tank; the pressure when filling the hydrogen is 0.2Mpa;

[0048] S3: Fill the tank in S2 with high-temperature silane at 400°C until a silicon film with a thickness of 200nm is formed on the inner wall of the tank; keep the pressure at 0.2Mpa when filling the tank;

...

Embodiment 1C

[0051] The preparation process of the tank body is the same as in Example 1A, and the coating steps are as follows:

[0052] S1: Vacuumize the sampling tank, fill it with nitrogen, evacuate it, and then fill it with nitrogen, and repeat this cycle until the nitrogen in the sampling tank accounts for more than 99% of the gas in the tank; both vacuuming and nitrogen filling are carried out at room temperature; Keep the pressure at 0.6Mpa during nitrogen treatment;

[0053]S2: Vacuumize the sampling tank and fill it with high-temperature hydrogen at 600°C; evacuate again and fill it with high-temperature hydrogen, and repeat this cycle until the hydrogen in the sampling tank accounts for more than 99% of the gas in the tank; the pressure when filling hydrogen is 0.6Mpa;

[0054] S3: Fill the tank in S2 with high-temperature silane at 600°C until a silicon film with a thickness of 300nm is formed on the inner wall of the tank; keep the pressure at 0.6Mpa when filling the tank;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com