Lining end module for embedded water stop belt

A waterstop and end form technology, which is applied in wellbore lining, tunnel lining, underground chambers, etc., can solve the problems of waste of labor and materials, easy operation of workers, and high height, etc., so as to save construction costs and reduce labor. Cost and material cost, anti-twist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

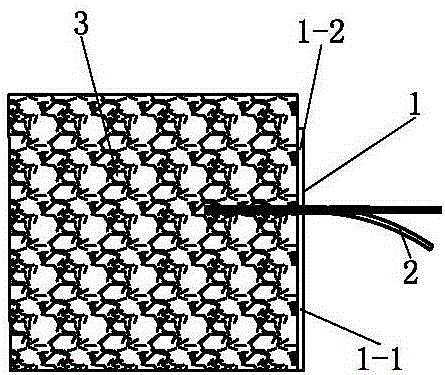

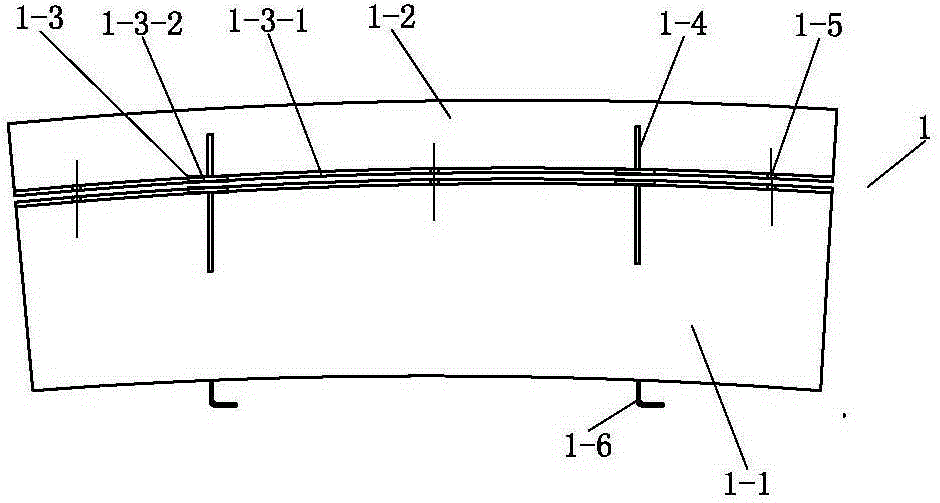

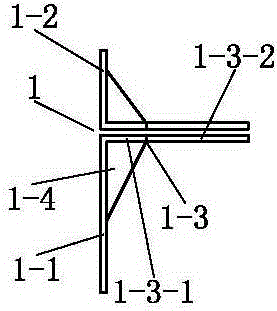

[0063] Such as Figure 2 to Figure 11 As shown, this embodiment provides a lining end form for a buried waterstop, including an outer end form 1-1 and an inner end form 1-2, the outer end form 1-1 and the A slit for clamping the waterstop 2 is formed between the inner end molds 1-2, and the opposite sides of the outer end mold 1-1 and the inner end mold 1-2 constitute the two sides of the slit, which It is characterized in that: the outer sides of the outer end mold 1 - 1 and the inner end mold 1 - 2 are respectively provided with fixing parts 1 - 3 for fixing the water stop belt 2 .

[0064] In this embodiment, due to the adoption of the technical means that the outer sides of the outer end mold and the inner end mold are respectively provided with fixing parts for fixing the waterstop, the fixing parts can greatly enhance the clamping of the buried waterstop. The holding effect can effectively fix the buried waterstop, so it can effectively prevent the displacement of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com