Prestressed reinforced concrete beam transforming and reinforcing method

A technology for reinforced concrete beams and prestressed beams, applied in joists, girders, truss beams, etc., can solve the problems of unsatisfactory clearance and low overall floor height, and achieve the effect of ensuring bearing capacity and enhancing bearing and supporting capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below.

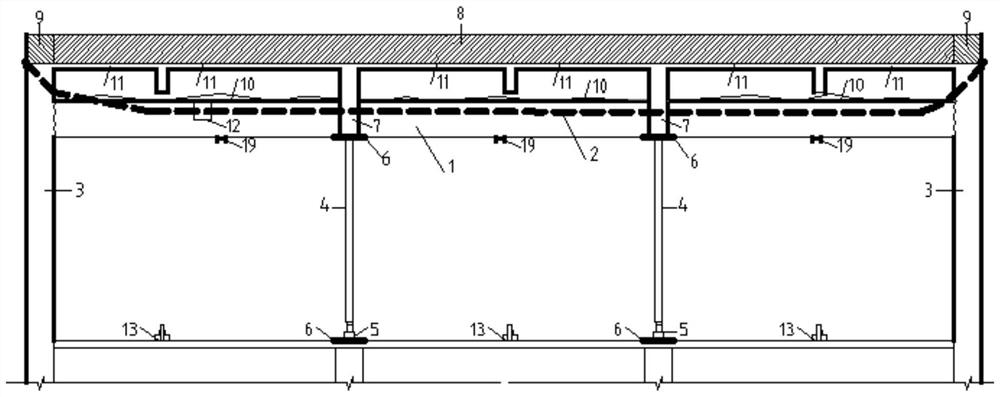

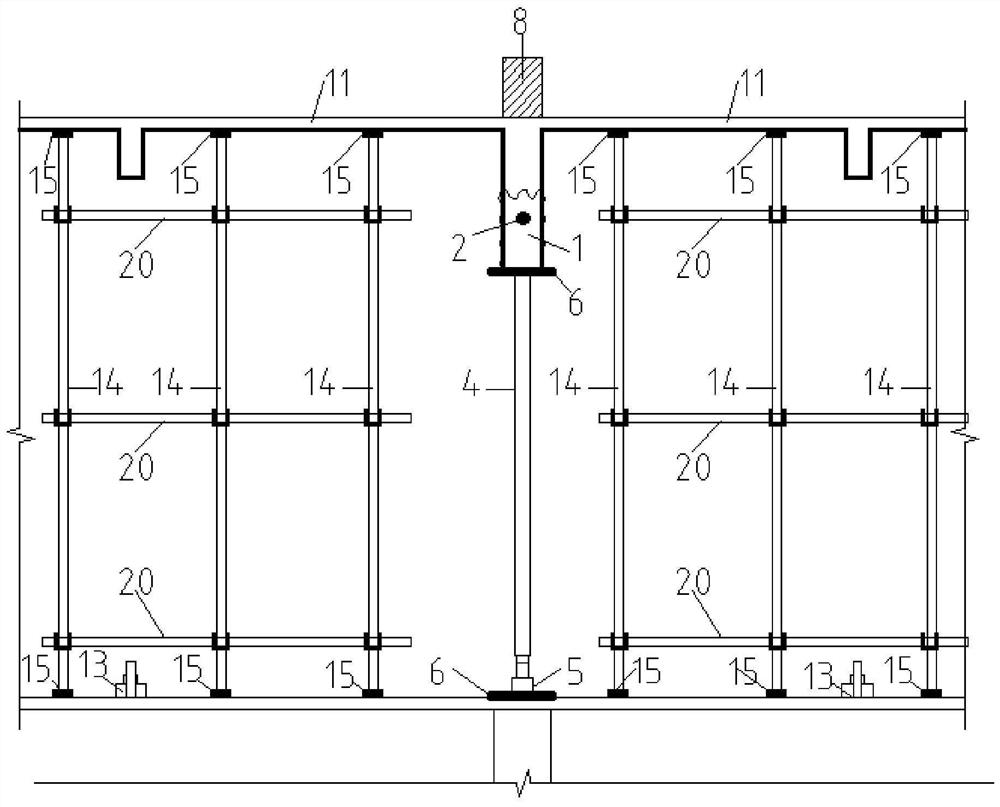

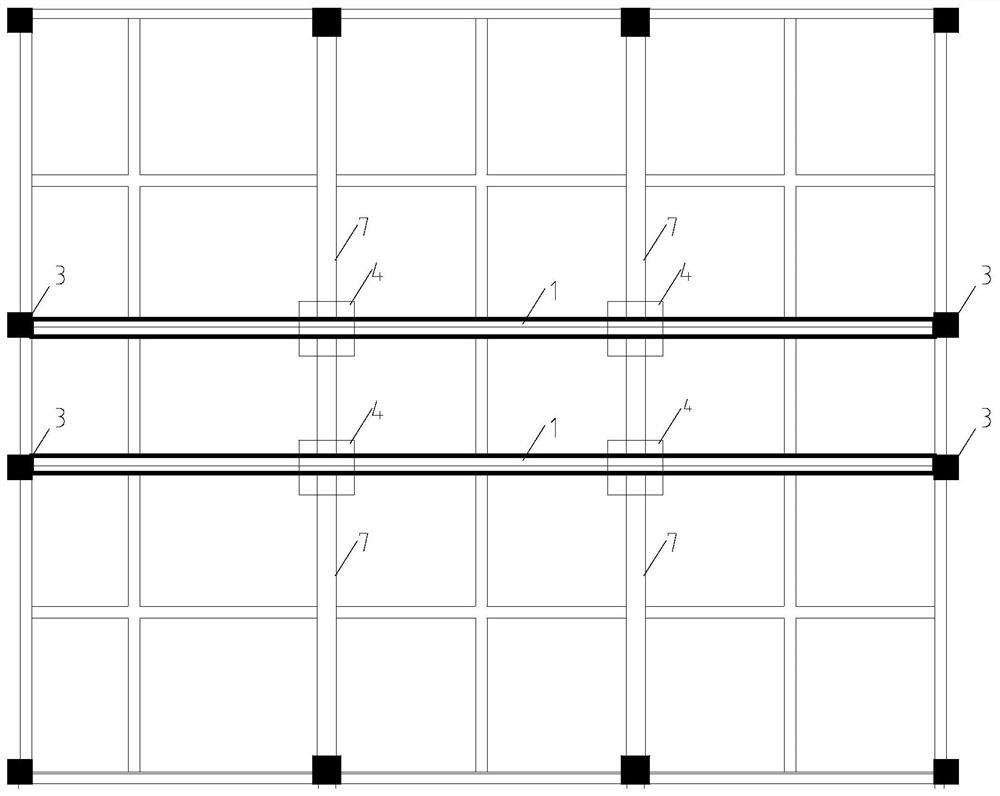

[0051] Such as Figure 1 to Figure 7 As shown, a prestressed reinforced concrete beam reconstruction and reinforcement method includes the following steps:

[0052] Step 1, the jacking support of the prestressed beam 1;

[0053] First plan the layout positions of each jack 5 and steel pipe column 4, then lay each jack 5 flat, and lay a steel backing plate 6 at the bottom of each jack 5; then, vertically set the steel pipe column 4 on the corresponding above the jack 5, and make the top of the steel pipe column 4 contact smoothly with the upper vertical main beam 7 through the steel backing plate 6, and then load the bottom end of the steel pipe column 4 upwardly through the jack 5;

[0054] As a preference, the steel backing plate 6 has a thickness of 10mm; for effective support, the steel pipe column 4 is a square steel pipe column with a cross-section not less than 200mm×200mm and a wall thickness not less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com