Impermeable layer structure for refuse landfill

A technology of landfill and anti-seepage layer, which is applied in the direction of infrastructure engineering, protective devices, buildings, etc., can solve the problems of garbage decomposition, soil and water pollution, pollution, etc., and achieve good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

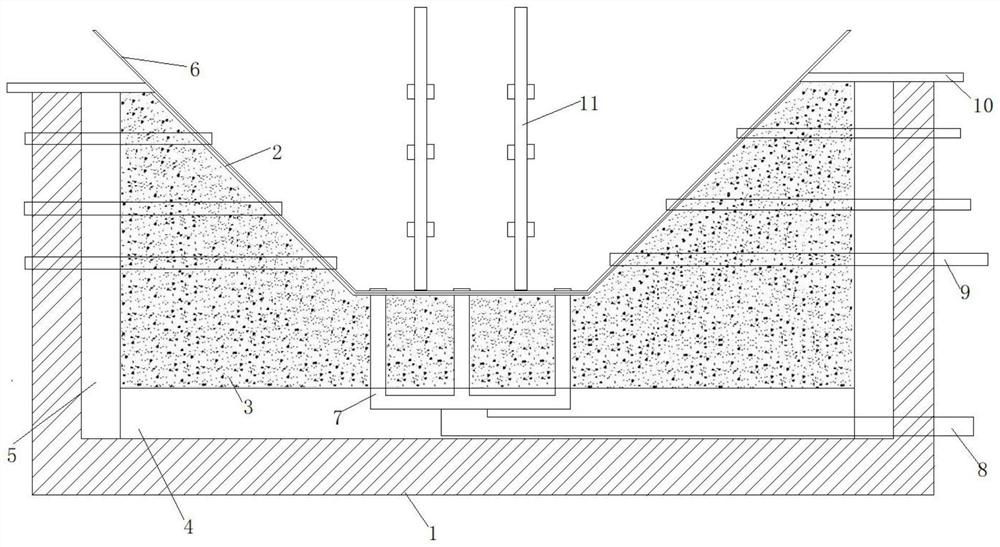

[0019] Such as figure 1 As shown, the structure of the anti-seepage layer for the landfill mainly includes a foundation 1, a landfill pit body 2, a filling layer 3, an isolation layer 4, an adsorption layer 5, an anti-seepage layer 6, a liquid leakage pipe 7, and a liquid outlet pipe 8. Side outlet pipe 9, cover plate 10, liquid inlet pipe 11, the landfill pit body 2 is the pit body on the surface of the foundation 1, the filling layer 3 is arranged outside the landfill pit body 2, and the partition layer 4 is arranged on the filling On the side of layer 3, the landfill pit body 2, partition layer 4, and adsorption layer 5 are integrally formed. After digging the pit body on the surface of the foundation 1, the landfill pit body 2, partition layer 4, and adsorption layer 5 are cut off by concrete slabs. , the landfill pit body 2 is located in the middle, the partition layer 4 is located at the bottom of the landfill pit body 2, and the adsorption layer 5 is located on the left...

Embodiment 2

[0023] An anti-seepage layer structure for a landfill site. The anti-seepage layer structure for a landfill site is to dig a pit on the surface of a foundation as a pit body for landfill, and an anti-seepage layer is laid inside the pit body. The anti-seepage layer It is HDPE film, and the anti-seepage layer is extended to the periphery of the pit body. After the anti-seepage layer is laid, it is filled with garbage. After the garbage is filled, the extended anti-seepage layer is covered on the garbage. After covering, the surface of the anti-seepage layer is covered with soil, planted vegetation, construction When completed, record the completion time;

Embodiment 3

[0025] An anti-seepage layer structure for a landfill site, the anti-seepage layer structure for a landfill site mainly includes a foundation, a landfill pit body, a filling layer, a partition layer, an adsorption layer, an anti-seepage layer, a liquid leakage pipe, an outlet For the liquid pipe, after digging a hole on the surface of the foundation, use a concrete slab to separate the landfill pit body, partition layer, and adsorption layer. The landfill pit body is located in the middle, the partition layer is located at the bottom of the landfill pit body, and the adsorption layer is located On the left and right sides of the landfill pit, liquid leakage pipes and liquid outlet pipes are installed at the bottom of the landfill pit. The foundation is the selected location of the garbage filling site. According to the designed volume, the pit body is dug on the surface of the foundation, and the pit body is dug and installed. The landfill pit body, partition layer, adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com