Method for measuring and regulating temperature of regenerative chamber

A regenerator and temperature measurement technology, which is applied in the heating of coke ovens, furnace safety devices, combustible gas heating coke ovens, etc., can solve the problem of difficult measurement and adjustment of the temperature difference between gas regenerators and air regenerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

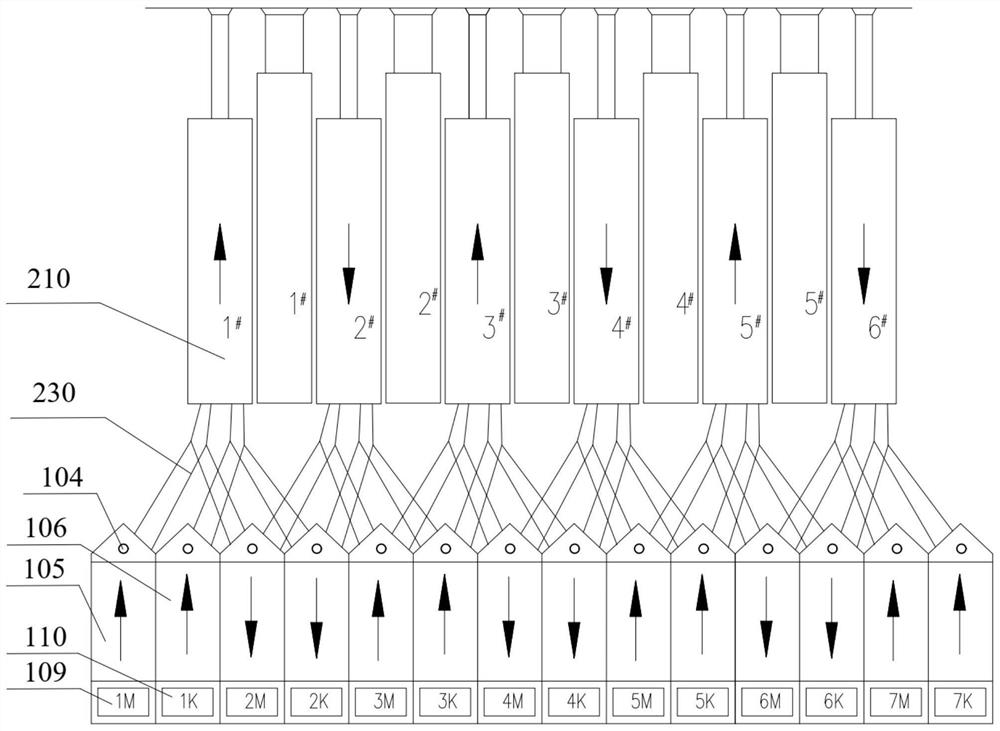

[0077]A group of coke ovens, numbered 1#2#, are 6m coke ovens of JN60-6F type with 2×55 holes. Coke oven gas is used for heating, the turnaround time is 19 hours, and the standard temperature is 1260 / 1310°C. The openings of the air inlet doors on the same side of the gas regenerator 105 and the air regenerator 106 are consistent, and the production is normal.

[0078] Further measurements and adjustments were made using the method of the invention. In this example, No. 1 coke oven No. 18 regenerator is selected for commissioning:

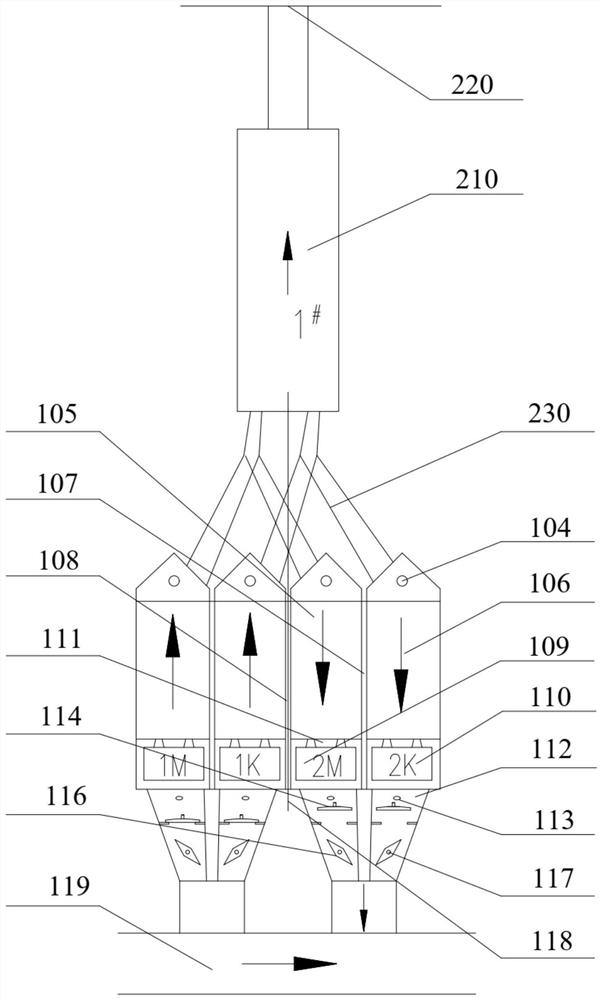

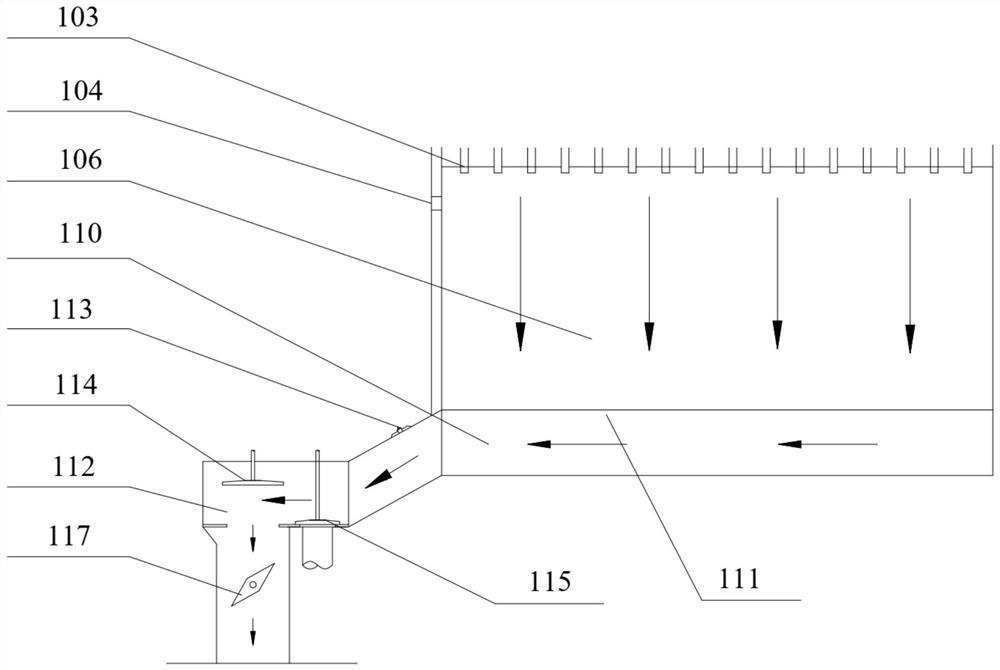

[0079] Insert a thermocouple with a paperless recorder into the temperature measuring hole 113 of the small flue, and measure the exhaust gas temperature of the gas small flue 109 and the air small flue 110 on the machine side and the coke side of the No. 18 regenerator of the No. 1 coke oven. Carry out online measurement, after five minutes of reversing, read the temperature of gas small flue 109 and air small flue 110 online at any time, compare ...

Embodiment 2

[0086] A group of coke ovens, numbered 6#7#, are 2×55 holes BS60-2 type 6m coke ovens. Blast furnace gas heating is used, the turnaround time is 19 hours, the standard temperature is 1260 / 1310°C, and the production is normal.

[0087] Further measurements and adjustments were made using the method of the invention. In this example, No. 7 coke oven No. 100 regenerator is selected for commissioning:

[0088] Insert a thermocouple with a paperless recorder into the small flue temperature measuring hole 113, and measure the exhaust gas temperature of the gas small flue 109 and the air small flue 110 on the machine side and the coke side of the No. 7 coke oven No. 100 regenerator. On-line measurement, after five minutes of reversing, read the temperature of the small gas flue 109 and the small air flue 110 online at any time, and compare the temperature difference between the small gas flue 109 and the small air flue 110 as the basis for on-site adjustment. After the measurement,...

Embodiment 3

[0096] The regenerative coke oven system of the third embodiment is basically the same as that of the first embodiment above, the difference between the two is that a simpler and easier-to-read plate thermometer is used for measurement.

[0097] In this embodiment, No. 86 regenerator of No. 2 coke oven is selected for commissioning:

[0098] Insert the disc thermometer into the small flue temperature measuring hole 113 to measure the exhaust gas temperature of the gas small flue 109 and the air small flue 110 on the machine side and the coke side of the No. 86 regenerator of the No. 2 coke oven. After five minutes, read and compare the temperature difference between the gas small flue 109 and the air small flue 110: the machine side is 21°C, and the coke side is 71°C. And the temperature at 20 minutes after reversing represents the temperature of the small flue before adjustment. The measurement results are shown in Table 3.

[0099] Because the temperature difference betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com