Resourceful treatment system and method for anaerobic fermentation biogas residues

An anaerobic fermentation and treatment system technology, applied in the field of anaerobic fermentation biogas residue resource treatment system, can solve the problems of insufficient consumption of anaerobic fermentation biogas residue production, environmental secondary pollution, high treatment cost, etc., to achieve Conducive to environmental protection and sustainable development, reduce processing time, improve the effect of processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

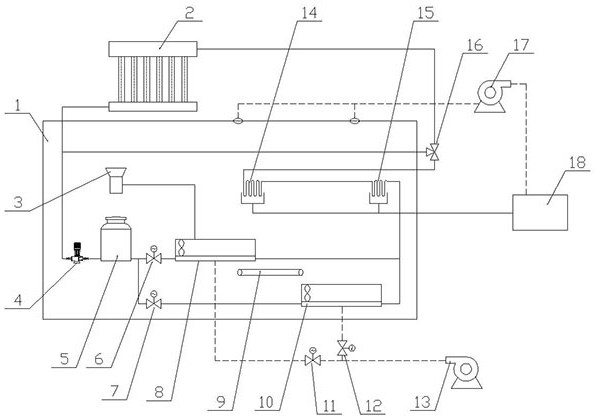

[0034] A resource processing system for anaerobic fermentation biogas residue of the present invention comprises a solar greenhouse 1, a solar heat collector 2, a mixer 3, a biological drying bed 8, a material conveyor belt 9, a fermentation bed 10 and a drying device; The specific structure is as figure 1 As shown, in the solar greenhouse 1, a mixer 3, a biological drying bed 8, a material conveyor belt 9, a fermentation bed 10 and a drying device are arranged successively, and a solar heat collector 2 is arranged on its top; 2 Connect with the lower part of the biological drying bed 8 and the lower part of the fermentation bed 10 respectively through the circulation pump 4, and transport the heated working medium to the lower part of the biological drying bed 8 and the lower part of the fermentation bed 10 for heat exchange; the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com