Steering shaft and ball frame structure for transmitting torque

A torque transmission and steering shaft technology, applied in the field of transmission shafts, can solve the problems of inconvenient assembly of steel ball cage, unstable transmission torque, insufficient lubrication of steel balls, etc., to achieve convenient assembly, stable transmission torque and high assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

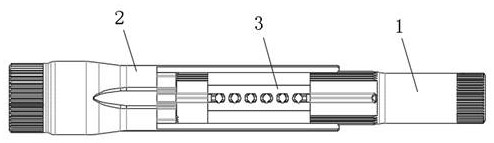

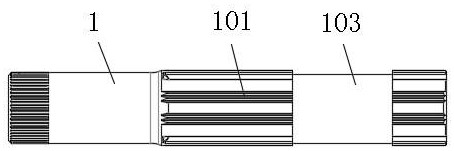

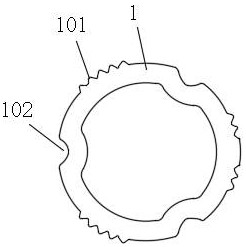

[0027] see Figure 1-7 and Figure 12 , the present invention provides a technical solution: a steering shaft and ball frame structure for torque transmission, including a spline shaft 1 arranged in a spline tube 2, and the spline shaft 1 is located at one end of the spline tube 2 Outer splines 101 and arc-shaped raceway 1 102 are arranged at equal intervals on the outer wall, and the inner wall of the spline tube 2 is respectively provided with matching holes at positions corresponding to the outer splines 101 and arc-shaped raceway 2 102. No less than three steel balls 4 are arranged between the inner spline 201 and the arc raceway 2 202, the arc raceway 1 102 and the arc raceway 2 202, and the outer spline 101 and the inner spline 201 are clearance fit, the outer wall of the spline shaft 1 is provided with a ring groove 103 at the position of the outer spline 101, and the spline shaft 1 and the spline shaft 2 are located in the corresponding ring groove 103 A steel ball c...

Embodiment 2

[0029] see Figure 8-10 , this embodiment is a further improvement on Embodiment 1: the steel ball cage 3 also includes a connecting plate 303, and the side walls of each adjacent two arc-shaped frame bodies 301 are connected through the connecting plate 303 to form A closed ring structure, the connecting plate 303 and the arc-shaped frame body 301 are all integral structures, and at least one connecting plate 303 is provided with an opening groove 304, the length of the connecting plate 303 is less than the length of the ring groove 103, The opening groove 304 is a "Z"-shaped structure, and the opening groove 304 runs through the side wall of the connecting plate 303, the steel ball cage 3 is a ball cage structure, and the steel ball cage 3 is provided with a "Z"-shaped opening Groove 304, just wrap the steel ball cage 3 at the position of the ring groove 103 on the spline shaft 1, which is convenient for the assembly of the steel ball cage 3, reduces the difficulty of assemb...

Embodiment 3

[0031] see Figure 11 , this embodiment is a modification of the second embodiment, the difference is that: the opening groove 304 is a straight groove structure, and the opening groove 304 does not pass through the connecting plate 303, and the number of the opening groove 304 is multiple when the connecting plate The left and right ends of the side wall of 303 are staggered with opening grooves 304, and the open grooves 304 are set at the left and right ends of the connecting plate 304 to make the steel ball cage 3 more flexible. When assembling, the steel ball cage 3 is stretched and nested in The position of the ring groove 103 on the spline shaft 1 is enough, and the steel ball 4 is lubricated more fully, which reduces the wear of the steel ball 4 and makes the torque transmission more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com