Flexible additive manufacturing equipment

An additive manufacturing and equipment technology, applied in the field of flexible additive manufacturing equipment, can solve the problems of slow cooling speed of additive manufacturing raw materials, slow airflow speed, easy to produce softening, etc., to reduce heat transfer, increase solidification speed, Avoid catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

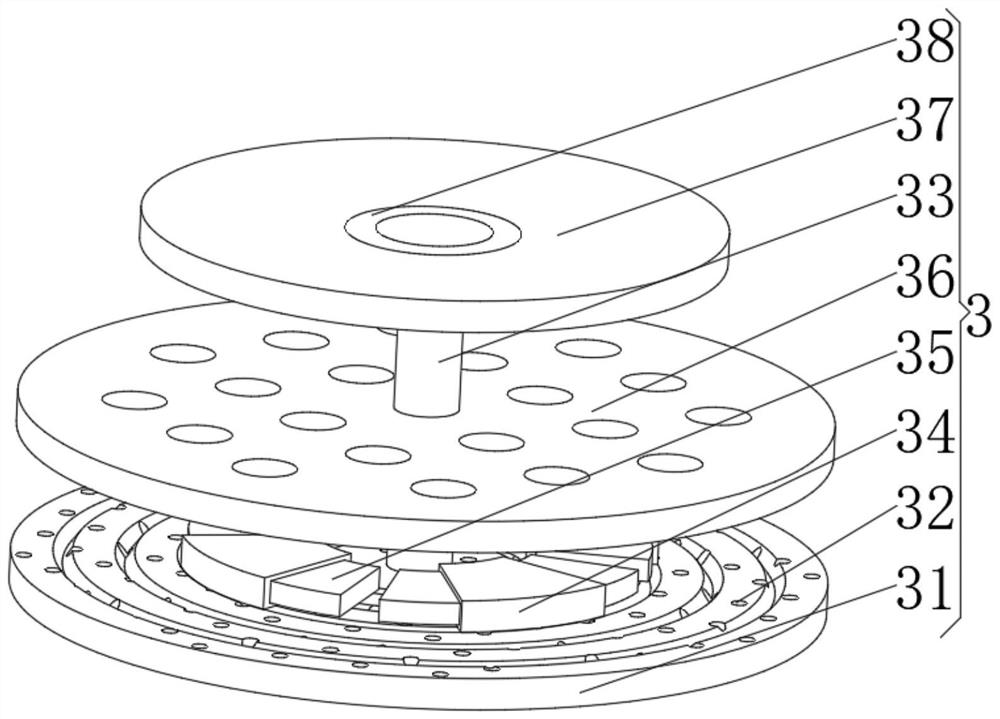

[0034] see Figure 1-3 , the present invention provides a technical solution: a flexible additive manufacturing equipment, specifically comprising:

[0035] Seat plate 1, the seat plate 1 has a circular plate body, and the injection fan 2 installed on the top of the circular plate body, and the manufacturing stage 3 installed on the top of the injection fan 2, and the injection fan 2 installed on the top of the circular plate body The air ring plate 4 on the outside of the fan 2, and the spiral track 5 installed on the inner surface of the air ring plate 4, and the manufacturing device 6 installed on the inner surface of the spiral track 5, and the door 7 installed on the front of the air ring plate 4, through The design of the injection fan 2 and the spiral track 5 circulates and gathers the airflow, and quickly and intensively cools the additively manufactured components to ensure the rapid hardening of the components themselves, preventing excessive accumulation of the comp...

Embodiment 2

[0041] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the manufacturing device 6 includes:

[0042] Track bar 61, this track bar 61 has convex bar body, and the driver 62 that is installed on the outer surface of convex bar body, and the rotator 63 that is installed on convex bar body two ends, and the shaping machine 64 that is installed in driver 62 bottoms;

[0043] The supply arc plate 65 has an inner through plate body, a bearing cylinder 66 installed on the top of the inner through plate body, and a mixing device 67 installed on the bottom of the inner cavity of the bearing cylinder 66 . The design of the supply arc plate 65 separates the upper and lower components, reduces heat transfer, protects the components from thermal fatigue, and at the same time reduces the temperature of the raw materials for additive manufacturing, increasing the solidification speed of the raw materials.

[0044] The outer surface of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com