Composite film separation equipment

A technology of composite film and separation equipment, applied in recycling technology, plastic recycling, etc., can solve problems such as inability to use electrostatic separation, impractical manual separation, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

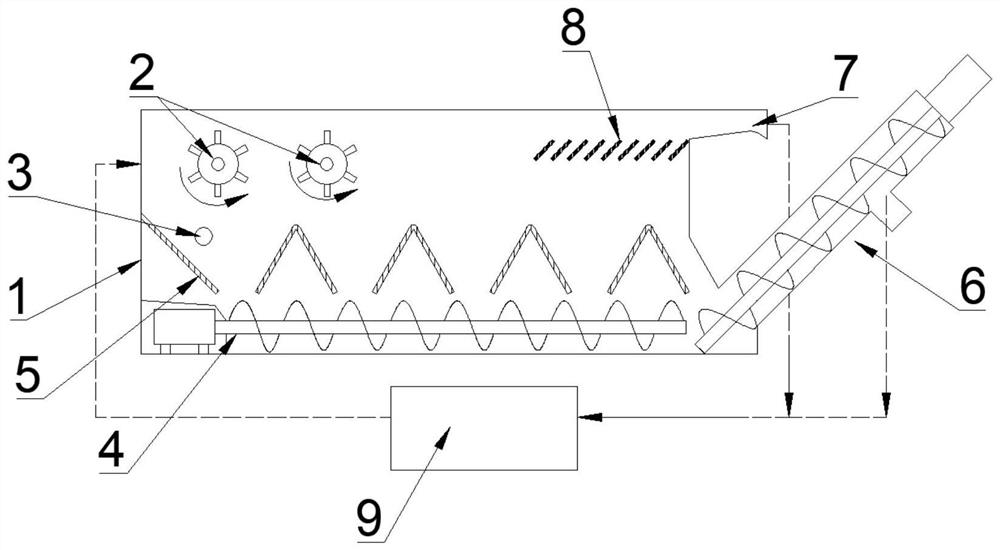

[0027] see figure 1 , The composite membrane separation equipment of the present invention includes a cleaning tank 1, a breaking device 2 arranged in the cleaning tank 1, a sedimentation anti-disturbance device and a conveying device.

[0028] see figure 1 , the dispersing device 2 is arranged at the material inlet of the cleaning tank 1, and is used to break up the composite film entering the cleaning tank 1 and drive the cleaning liquid to flow forward, so that the plastic films of different film layers in the composite film are separated Open, wherein, the specific structure of described dispersing device 2 can be implemented with reference to existing device, for example comprises beating roller and be used for driving the beating driving mechanism of described beating roller to rotate, and described beating driving mechanism can be motor, by The motor drives the beating roller to rotate, not only the composite film entering the cleaning tank 1 can be broken up, but also...

Embodiment 2

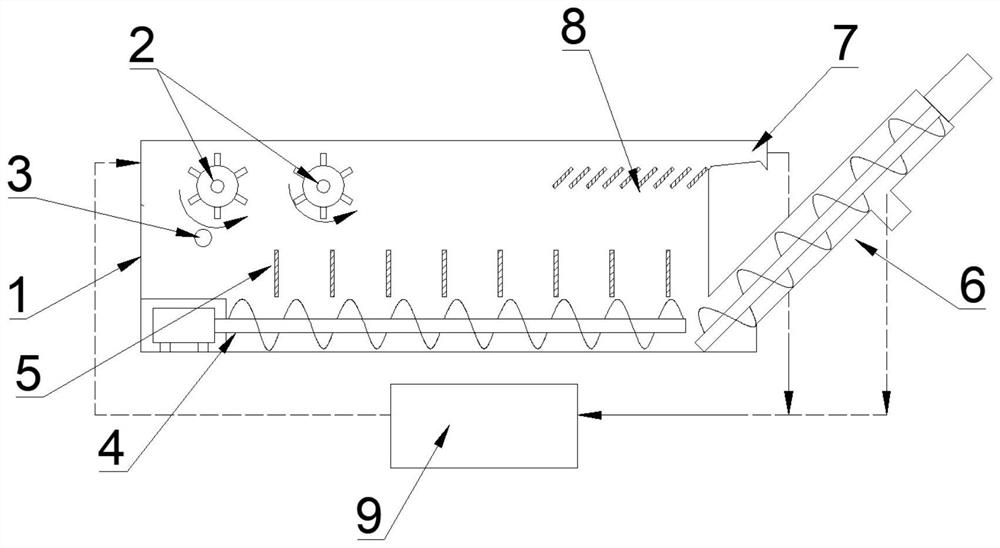

[0041] see figure 2 The difference between this embodiment and Embodiment 1 is that: the two partition plates 5 in the settling tank are vertically arranged; wherein, the gap between the two partition plates 5 constitutes the settling port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com