Ship sub-assembly auxiliary assembly system based on augmented reality

An auxiliary assembly and augmented reality technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of long time consumption and low synchronization efficiency, and achieve the effect of convenient backtracking, reducing assembly errors, and improving acquisition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

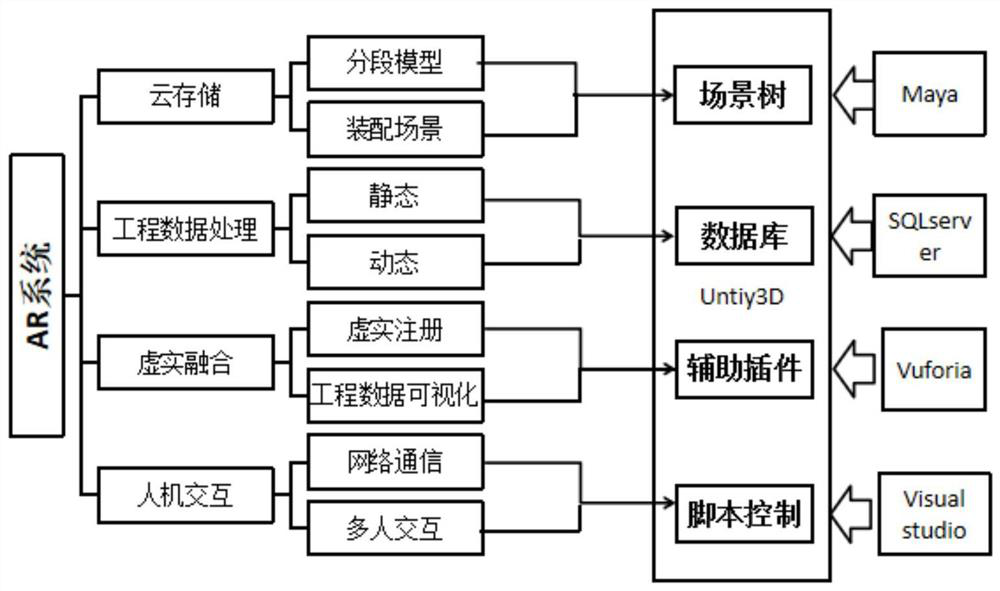

[0039] see Figure 1-4 , an augmented reality-based auxiliary assembly system for ship crews, including a cloud storage module, an engineering data module, a virtual-real fusion module, and a human-computer interaction module;

[0040] The cloud storage module includes a segmentation model creation unit and an assembly scene storage unit. It models all the plates in the ship group assembly process, converts the created plate model into an AB model through model conversion, and then creates an xml file, and Store it in a network disk;

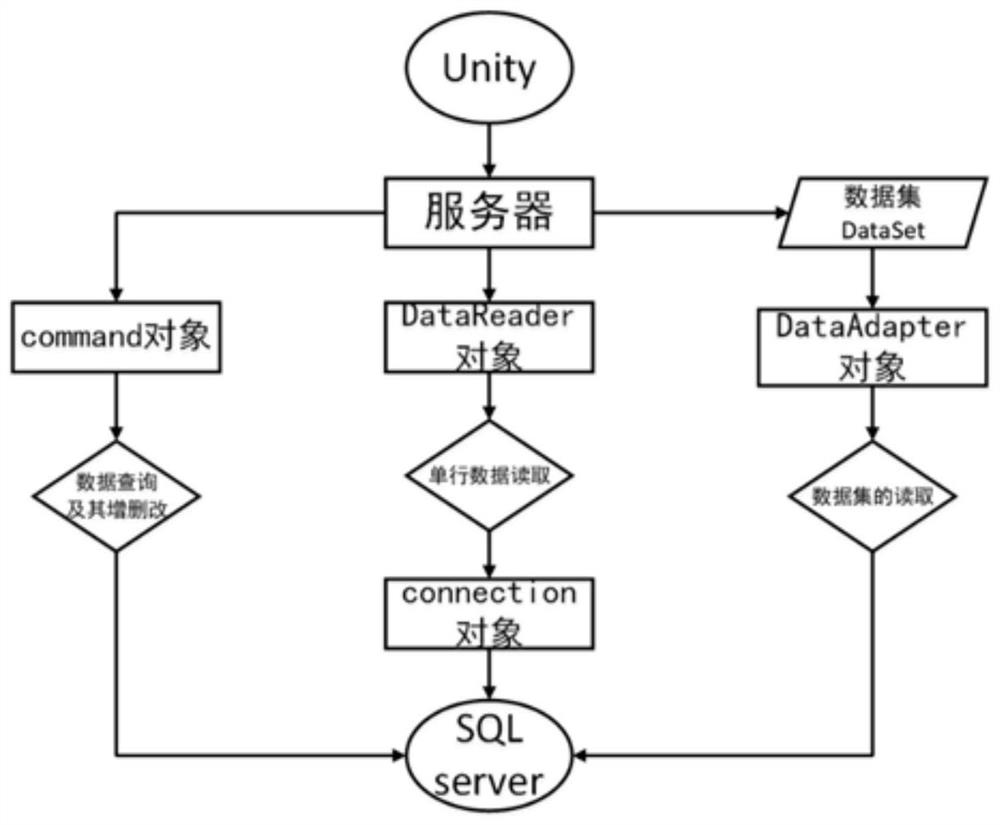

[0041] Engineering data module, including static data unit and dynamic data unit, stores the real-time data and UI display data generated during the ship assembly process;

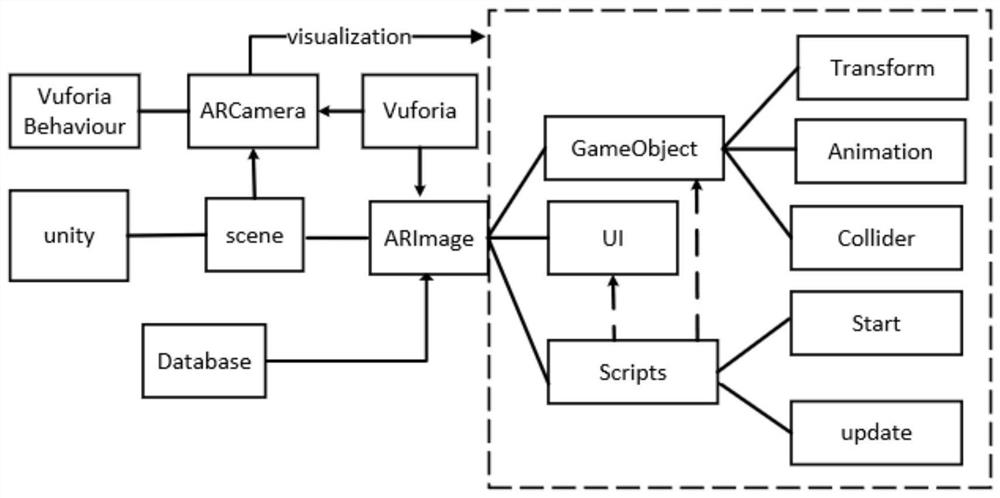

[0042] The virtual-real fusion module includes a virtual-real registration unit and an engineering data visualization unit, and uses the Vuforia augmented reality software development kit for 3D registration;

[0043] The human-computer interaction module includes a networ...

Embodiment 2

[0057] see Figure 1-4 , based on Example 1 but differing in that,

[0058] An augmented reality-based intelligent assembly auxiliary system for ship crews, including a cloud storage module, an engineering data module, a virtual-real fusion module, and a human-computer interaction module;

[0059] The cloud storage module constructs virtual scenes through Unity, renders the real-scale ship panel model, adds shaders to it, makes it have better lighting effects, and facilitates the process of combining virtual and real to be more realistic; using cloud storage technology Store the model, reduce the proportion of system memory, and download the model online through network communication technology during the model rendering process; design the UI in world coordinates and local coordinates according to the real information of the ship panel to realize real-time expression of assembly information; The ANIMATION design of the assembly process realizes the real-time guidance of the ...

Embodiment 3

[0065] see Figure 1-4 , based on Examples 1-2 but differing in that,

[0066] A ship intelligent auxiliary assembly system based on augmented reality, such as figure 1 As shown, it includes: the cloud storage module, which is mainly created by creating the models of all the plates in the ship group assembly process, converting them into AB models through model conversion, and then creating xml files for storage in Alibaba Cloud;

[0067] The engineering data module mainly stores the real-time data generated during the assembly process and the UI display data;

[0068] The virtual-real fusion module mainly uses vuforia for 3D registration;

[0069] The human-computer interaction module mainly involves the network communication function by programming the assembly operations involved in the assembly process.

[0070] The main function of 3D registration technology is to use computer technology to identify the position of the camera relative to the real scene, then display th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com