Gas sampling device, and corresponding method of rock stratum sample and gas sample

A gas sampling and rock formation technology, applied in the field of geological exploration, can solve problems such as inability to extract gas samples, inability to verify each other to improve the accuracy of exploration analysis results, and inability to establish a corresponding relationship between rock formation samples and gas samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

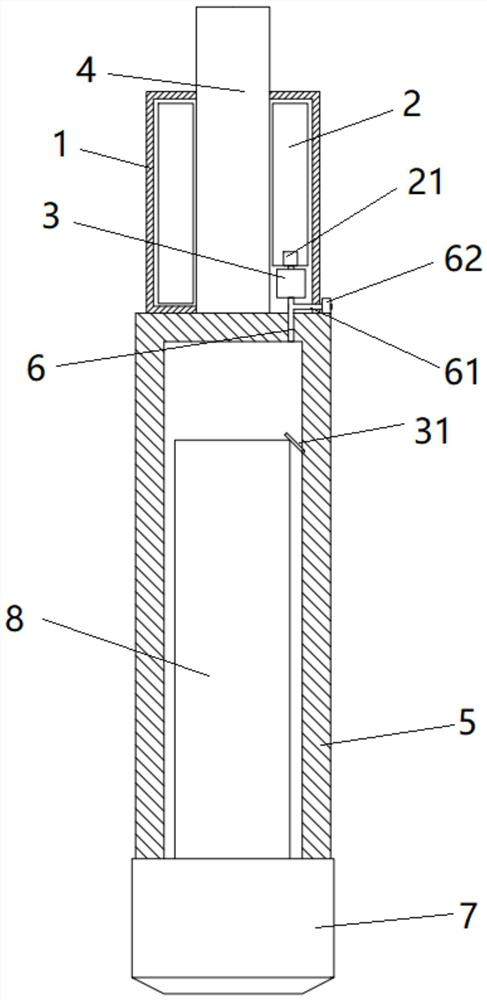

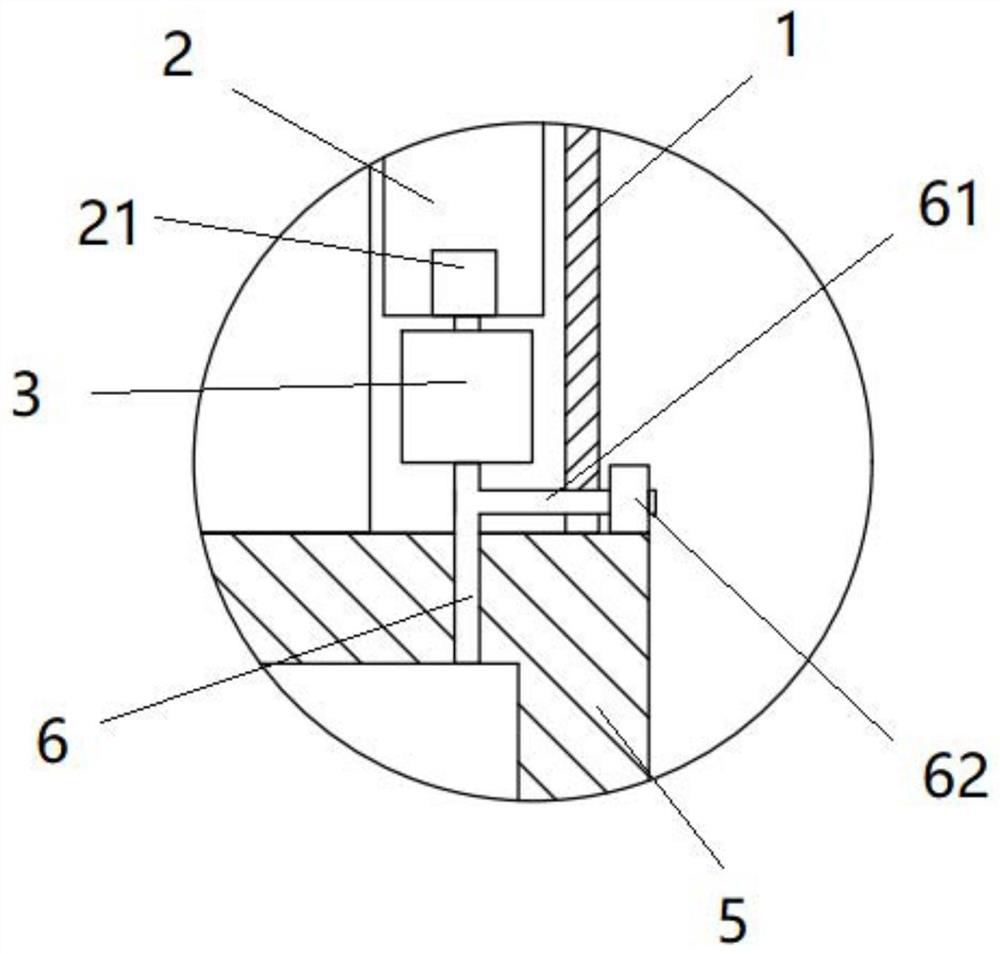

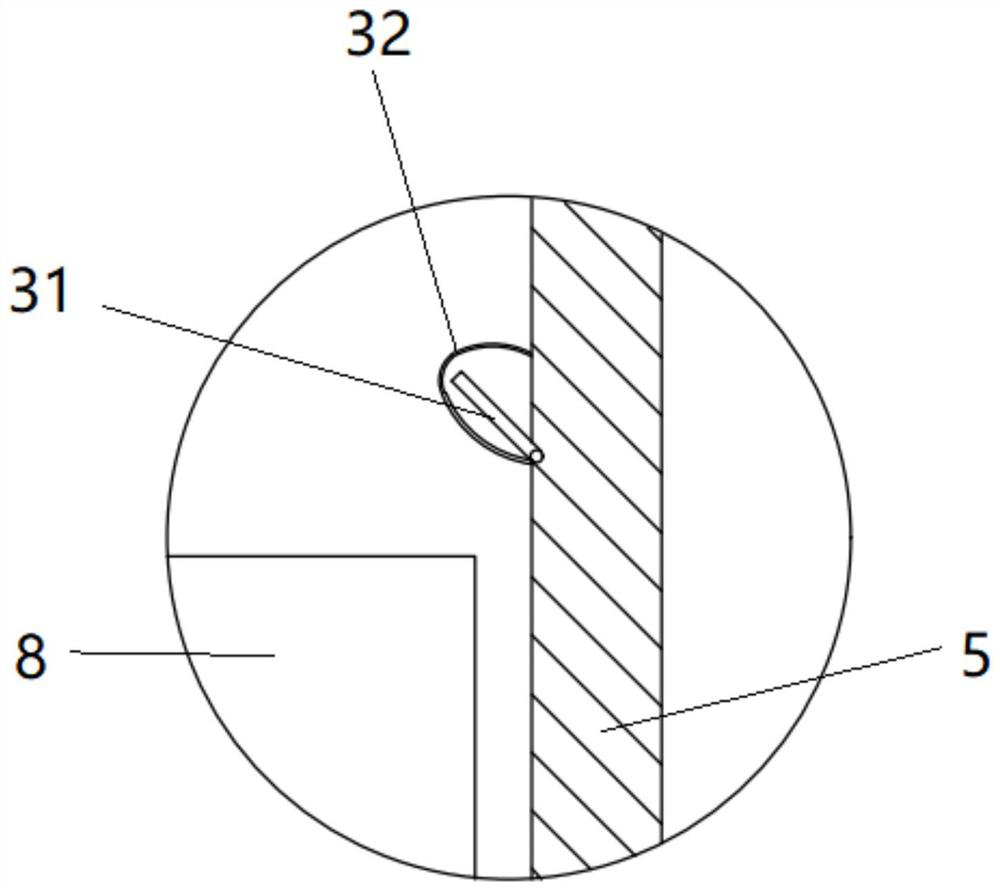

[0034] Such as figure 1 , convex 2 and image 3 As shown, this embodiment provides a gas sampling device, which is composed of a housing 1, a gas collection bag 2 and an air pump 3; the housing 1 is sleeved on the drill pipe 4, and the gas collection bag 2 is detachably accommodated in the housing 1 Inside, the input end of the air pump 3 communicates with the cavity of the rock formation sampler 5 through the air guide tube 6, and the output end of the air pump 3 communicates with the one-way inlet valve 21 arranged on the gas collection bag 2, forming a cavity formed by the rock formation sampler 5. The gas path that supplies gas to the gas collection bag 2 can fill the gas sample that enters the cavity of the rock formation sampler 5 together with the rock formation sample 8 into the gas collection bag 2 during the process of obtaining the rock formation sample 8 .

[0035] Due to the poor airtightness of the cavity of the conventional rock formation sampler 5, it is impos...

Embodiment 2

[0042] Such as figure 1 , convex 2 and image 3 As shown, on the basis of Embodiment 1, this embodiment proposes a method for establishing a corresponding relationship between rock formation samples and gas samples, including a drill bit 7, a rock formation sampler 5, a drill pipe 4 and a gas sampling device; the gas sampling device For the gas sampling device in Example 1, the specific method is as follows:

[0043] The drill pipe 4 pushes the rock formation sampler 5 and the drill bit 7 arranged at the bottom of the rock formation sampler 5 drills to the formation, and the gas sampling device is mounted on the drill pipe 4 and communicates with the cavity of the rock formation sampler 5; during the drilling process, The drill bit 7 sends the separated rock sample 8 into the cavity of the rock sampler 5, and the gas accompanying the rock sample 8 is filled into the gas collection bag 2 by the air pump 3 for preservation; after the drill pipe 4 is recovered, the rock sample 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com