Displacement monitoring method for double-flat-arm derrick construction process based on computer vision

A technology of computer vision and displacement monitoring, applied in calculation, height/horizontal measurement, measuring devices, etc., can solve the problems of difficulty in displacement monitoring, and achieve the effect of long monitoring time and wide monitoring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

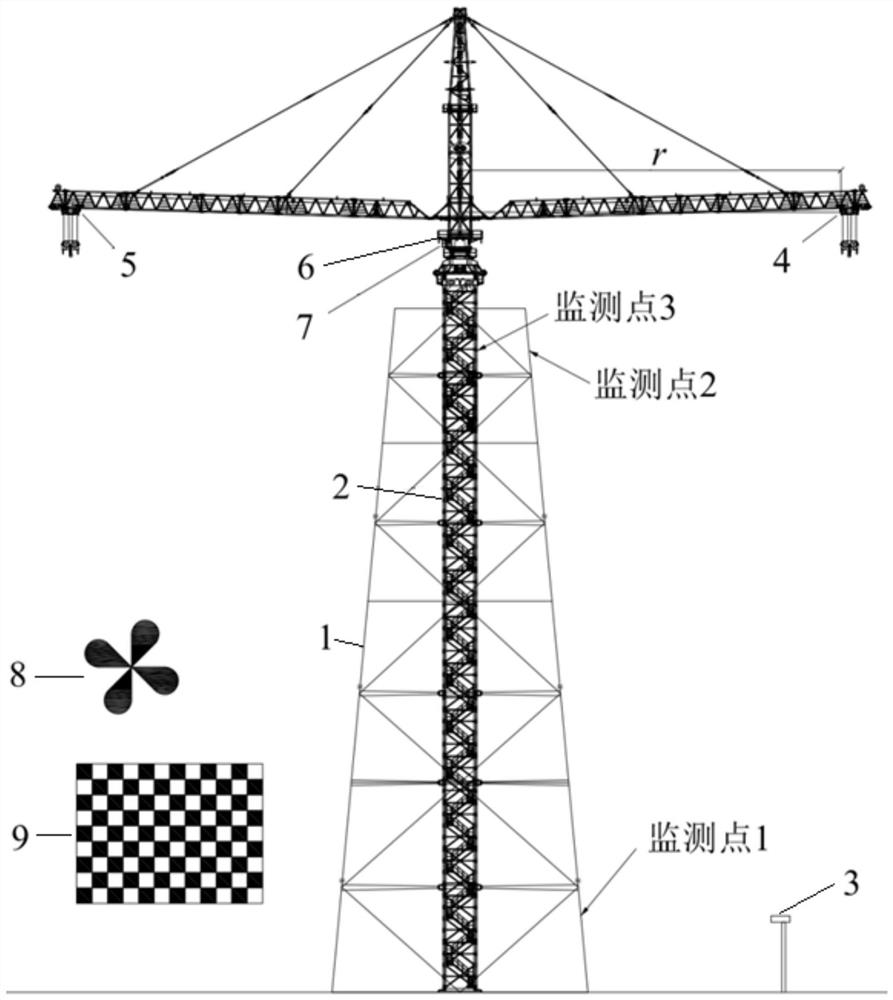

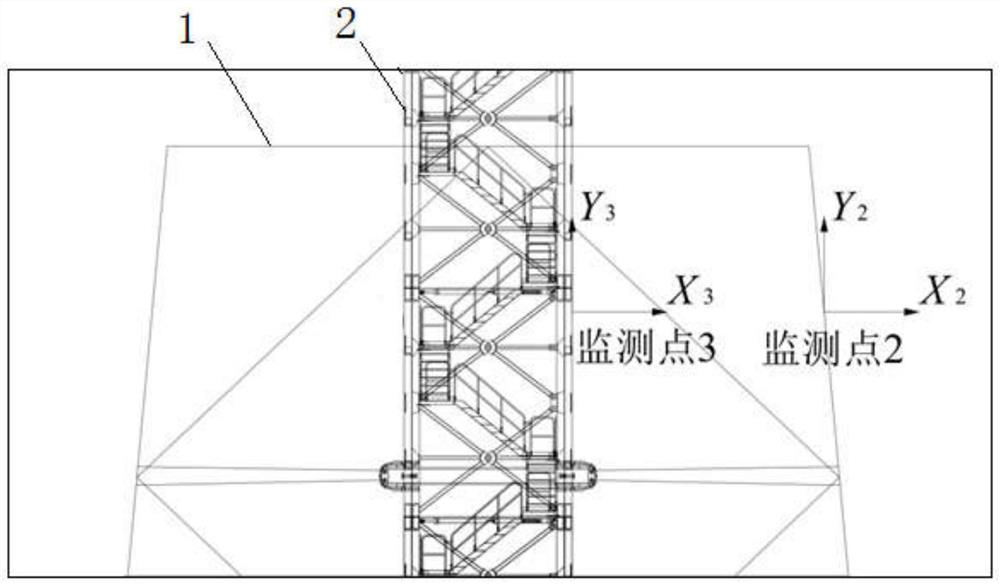

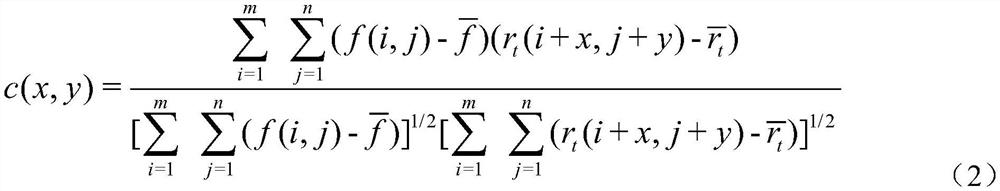

[0059] Such as figure 1 As shown, this embodiment provides a computer vision-based method for monitoring the displacement of the construction process of double-arm holding poles, including the following steps:

[0060] (1) Install a ground camera 3 near the transmission tower body 1 to ensure that the transmission tower body 1 is clearly and recognizably imaged in the video screen of the ground camera 3, and the camera angle of view is kept fixed.

[0061] (2) A flat-arm camera is respectively installed on the trolleys of the flat arms on both sides of the holding pole, which are respectively recorded as the first flat-arm camera 4 and the second flat-arm camera 5, so that they can move with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com