Grain aflatoxin and external defect high-flux sorting machine

A technology for aflatoxins and external defects, applied in the field of sorting, can solve problems such as the inability to detect food raw materials containing harmful biological toxins, and easy blockage of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

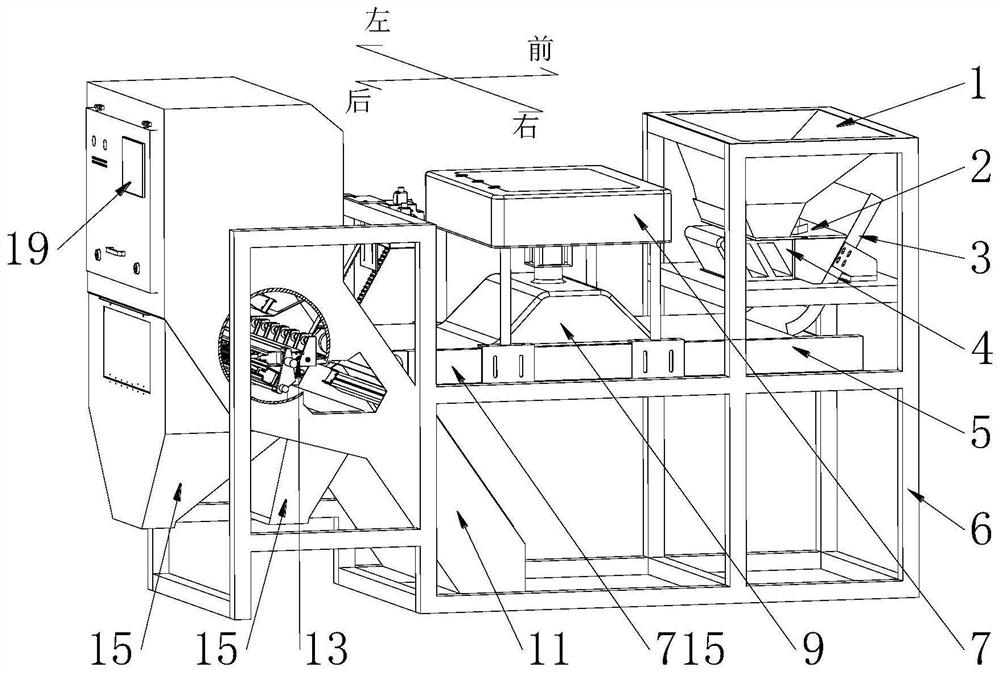

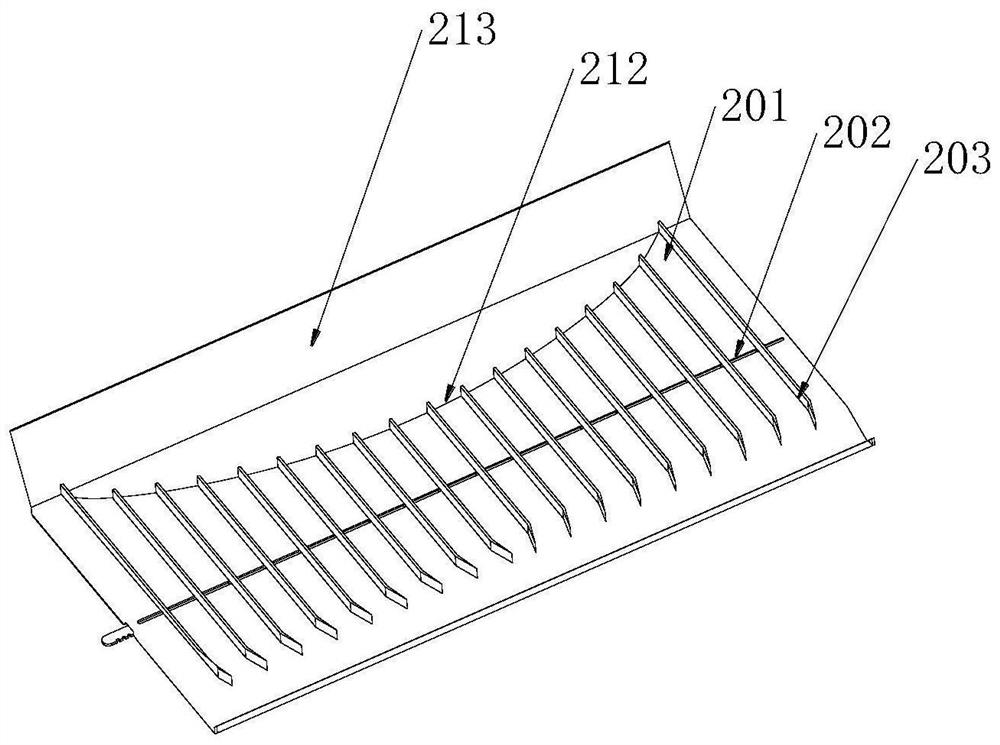

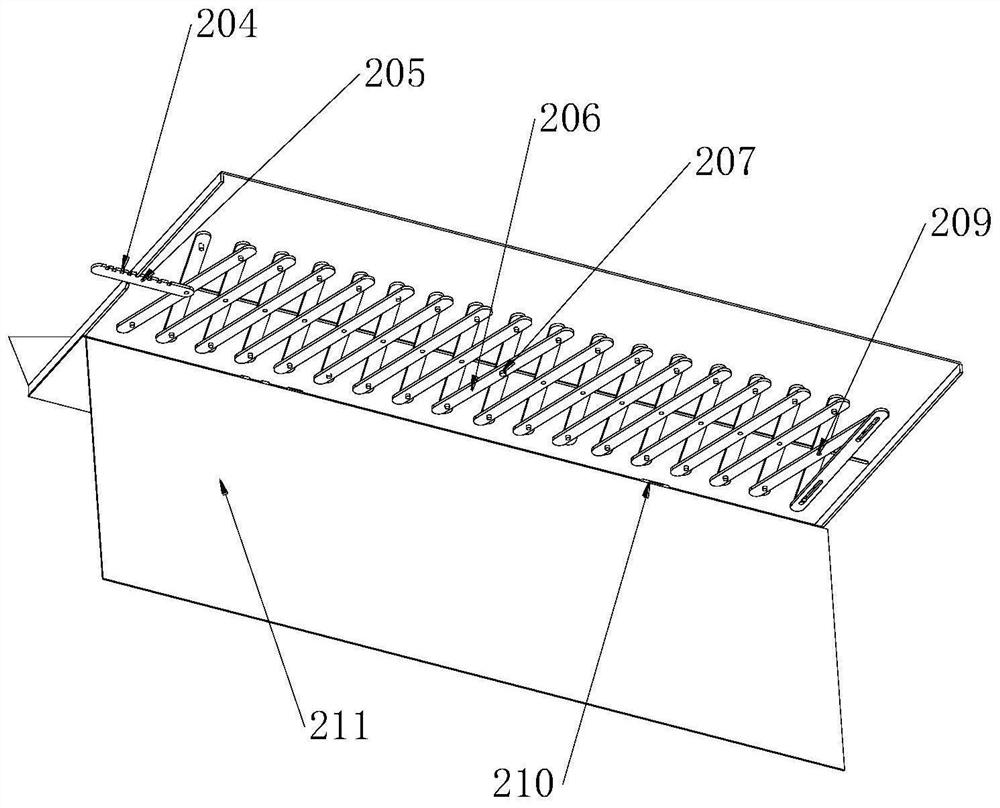

[0036] Such as Figure 1 to Figure 11 The shown embodiment of the present invention includes: a main frame 6, a high-speed belt group 5, a fluorescent detection device for toxic raw materials, a raw material external quality sorting device, a high-throughput online rejecting device 13, a power supply system and a material box 15, a photoelectric Box and industrial computer 8, wherein the main frame 6 used to provide support for the photoelectric box, the material box, the high-speed belt group 5 and the adjustable feeding device is arranged on the ground, and the main frame 6 is made of a 50×50 square tube according to the sorting The parts of the machine are placed and welded; the photoelectric box 11 is installed at the rear of the main frame 6, and the middle part of the photoelectric box 11 is equipped with a high-throughput online rejecting device 13 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com