Novel LED (Light Emitting Diode) car lamp part machining device

A technology of LED car lights and processing devices, which is applied in the directions of grinding machine parts, grinding driving devices, metal processing equipment, etc., can solve the problems of inconvenient adjustment and use of processing places, poor fixing and clamping effect, and inconvenient collection and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

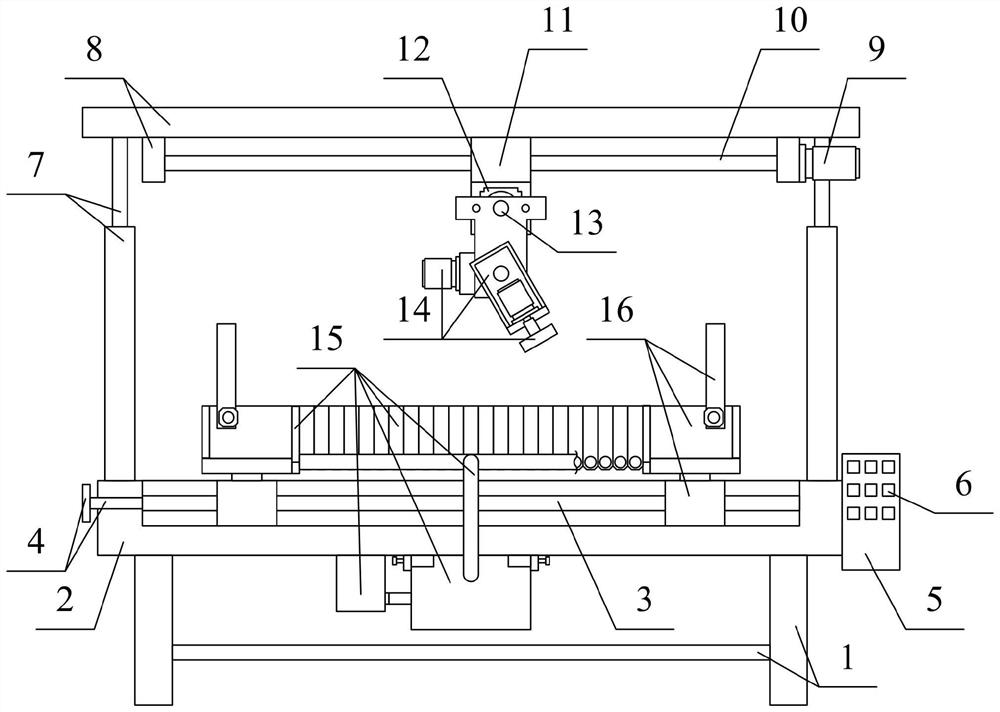

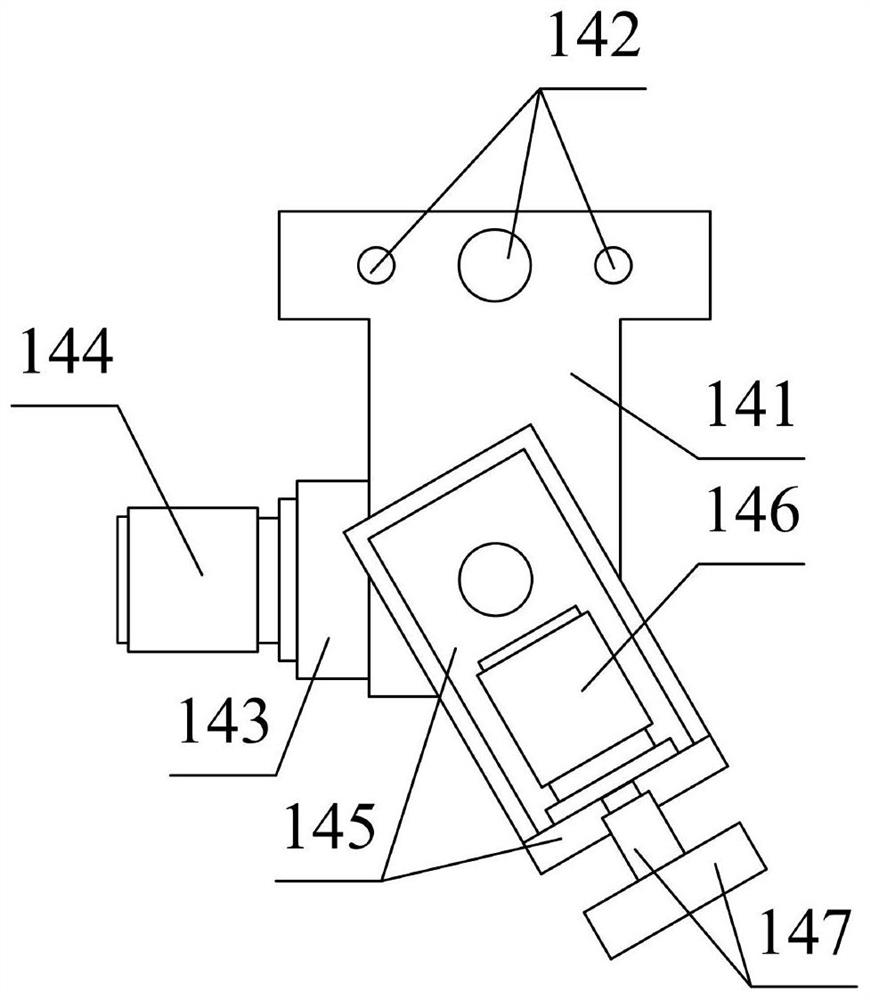

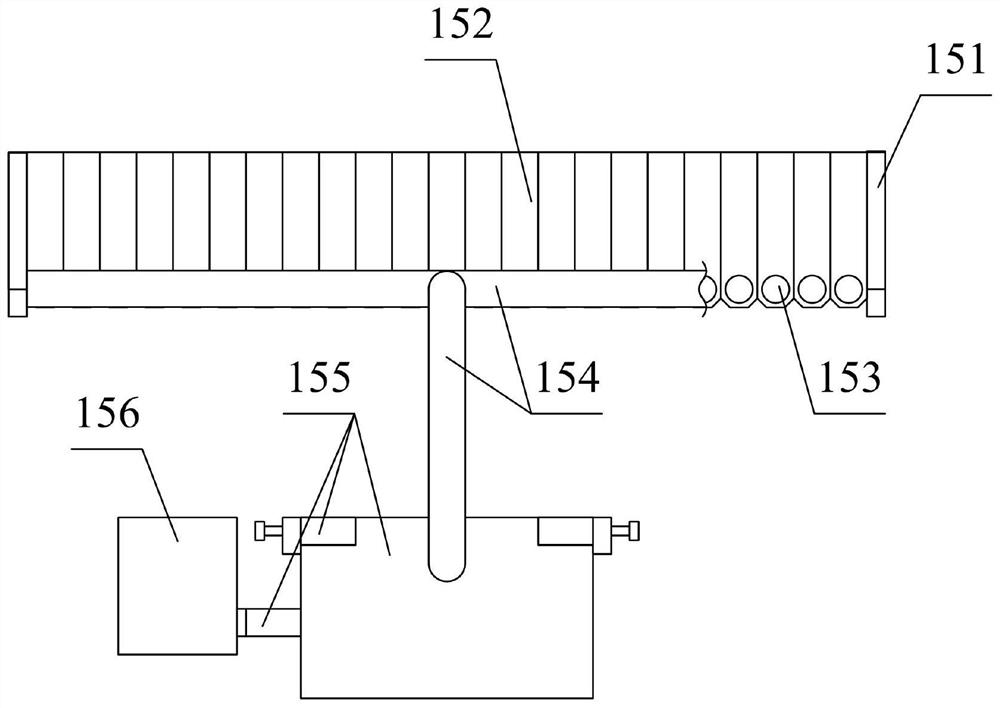

[0038] as attached figure 1As shown, a new type of processing device for LED car lamp parts, including a support frame 1, a support table 2, a two-way screw 3, a T-shaped rotating rod 4, a controller 5, a drive switch 6, an elevating electric cylinder 7, and a mounting top plate 8 , the first moving motor 9, the first screw rod 10, the lateral moving seat 11, the second moving motor 12, the second screw rod 13, adjusting the moving seat structure 14, collecting the folding box structure 15 and the auxiliary placement reinforcement seat structure 16, the described Bolts around the lower end of the support platform 2 are equipped with a support frame 1; the two-way screw rod 3 is installed on the upper side of the support platform 2 through bearings; the T-shaped rotating rod 4 passes through the left end of the support platform 2 and the two-way screw rod 3 Bolt connection; the controller 5 is bolted to the right end of the support platform 2, and the front end of the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com