Screw absorber

An adsorber and screw technology, applied in the field of metal small parts collection devices, can solve problems such as corporate waste, quality accidents, labor loss, etc., and achieve the effect of expanding the scope of activities and avoiding labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

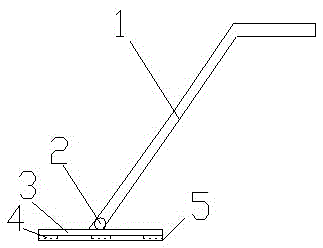

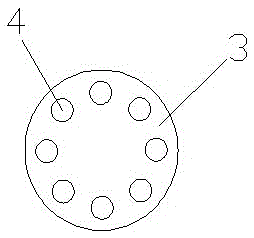

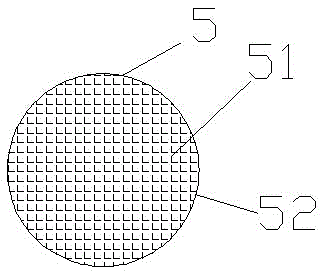

[0016] Such as figure 1 , figure 2 and image 3 As shown, a screw absorber includes a handle 1 and a suction plate 3, the structure of the handle 1 is "L" shape, the handle 1 and the suction plate 3 are movably connected by a spherical hinge 2, and an outer cover is arranged outside the suction plate 3 5. The outer cover 5 is flexibly connected to the suction disc 3 through internal and external threads. The handle 1 and the suction plate 3 of the present invention are movably connected through the ball hinge 2, which facilitates the bending of the handle 1, is better applicable to the collection of screws at the bottom of some machines, and expands the range of motion of the screw suction device.

[0017] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com