Universal metal mask welding method and manufactured universal metal mask

A metal mask and welding method technology, which is applied to welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor positioning accuracy of the mask plate in the accumulated deformation of welding, and achieve a simple and easy welding method, ensuring Overall position accuracy, improving the effect of cumulative extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

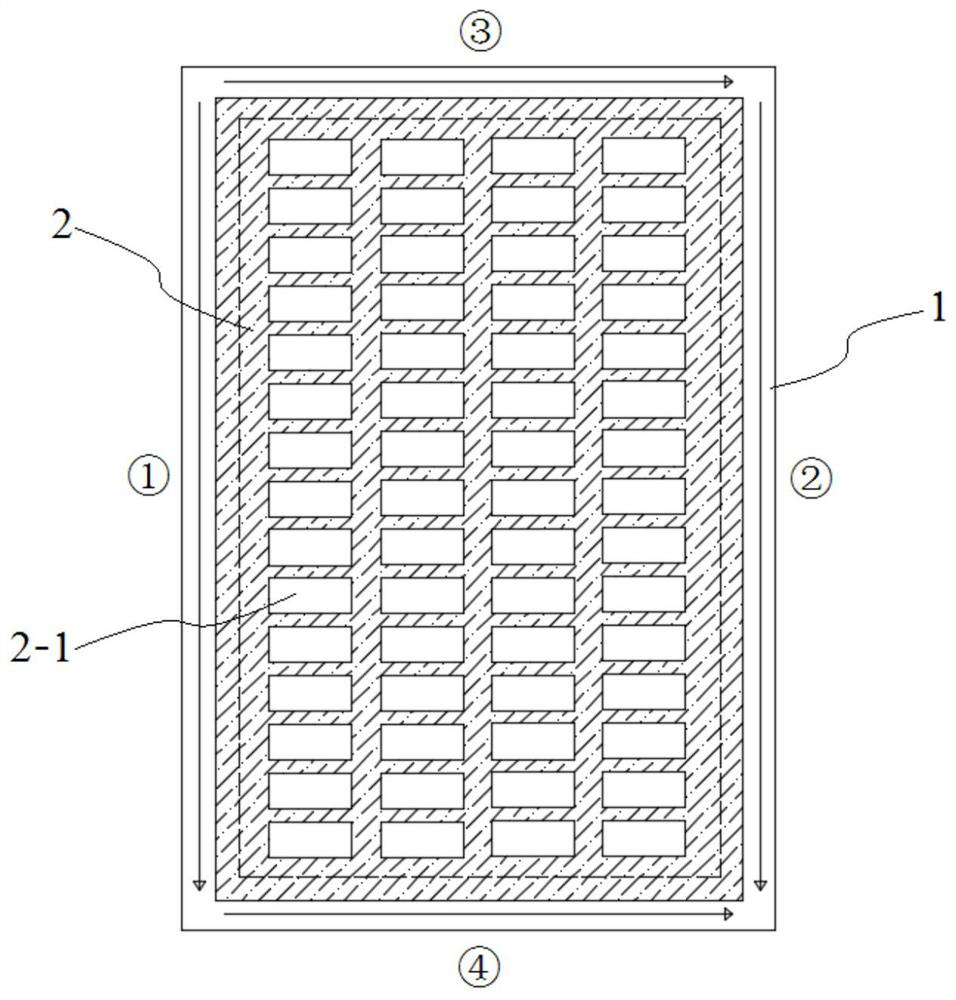

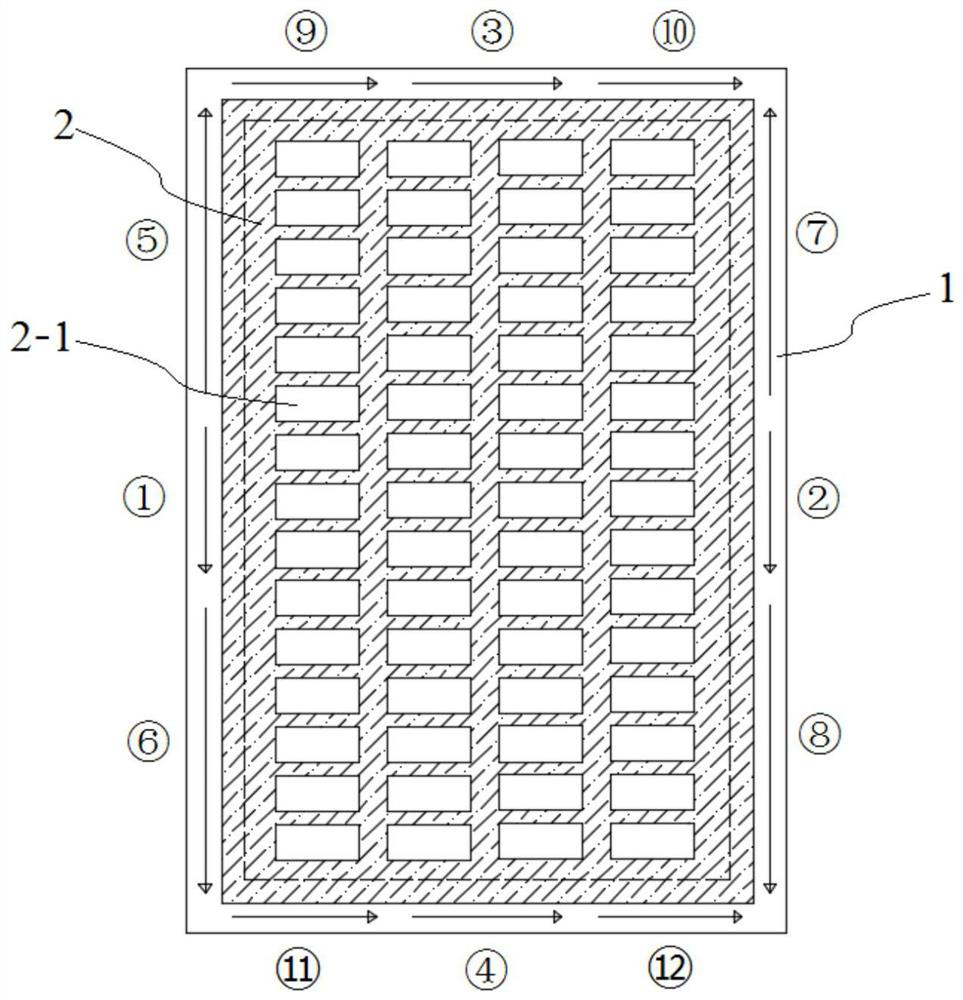

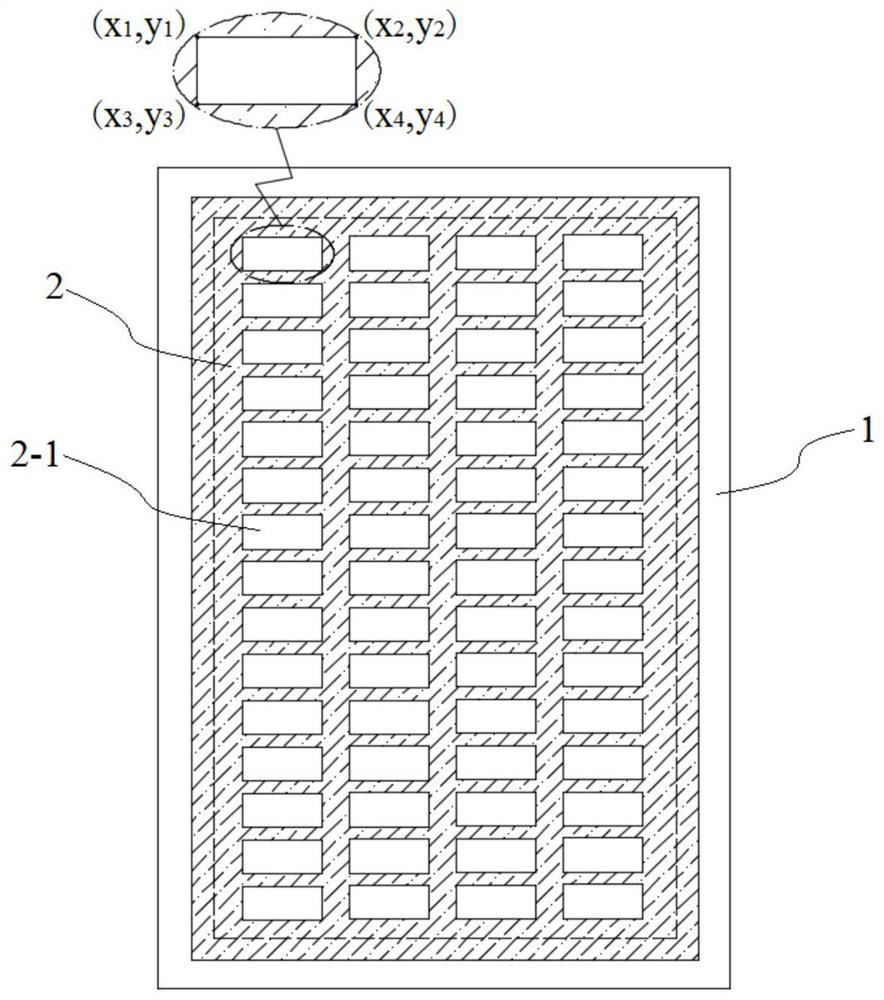

[0046] Such as figure 2 As shown, a kind of general metal mask welding method of the present embodiment comprises the following steps:

[0047] S1, position the stretching net around the rectangular mask net 2 on the upper surface of the rectangular metal frame 1; the stretching process of the rectangular mask net 2 and the rectangular metal frame 1 is similar to the prior art, and can be used in the existing net stretching equipment completed above, and will not be described in detail here; the positioning of the rectangular mask net 2 can be accurately positioned on the rectangular metal frame 1 through the positioning of the net, which is convenient for subsequent welding operations;

[0048] S2. Weld and fix the surroundings of the rectangular mask 2 on the rectangular metal frame 1 by spot welding; specifically, the following sub-steps are included:

[0049] S2-1, divide the long side and short side of the rectangular mask net 2 into welding areas, respectively divide e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com