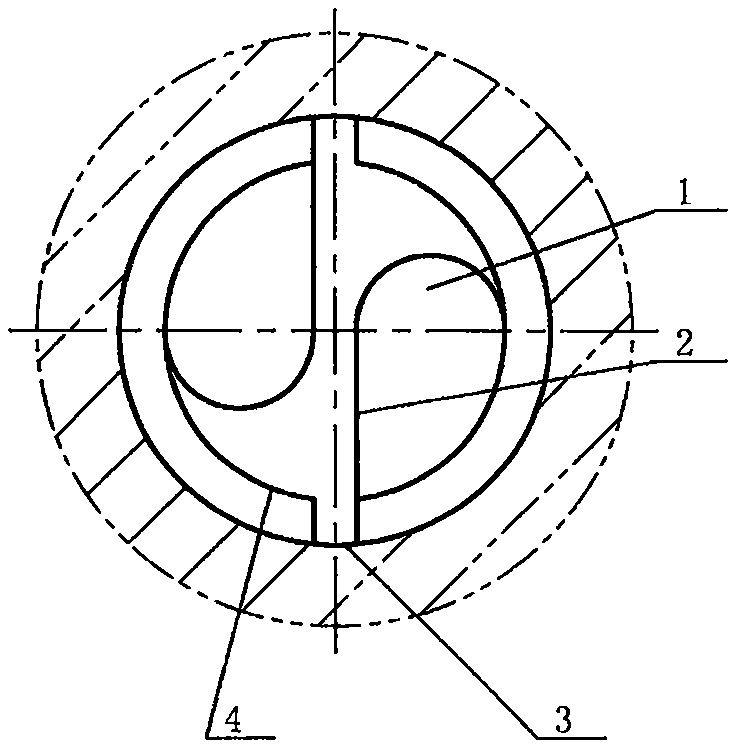

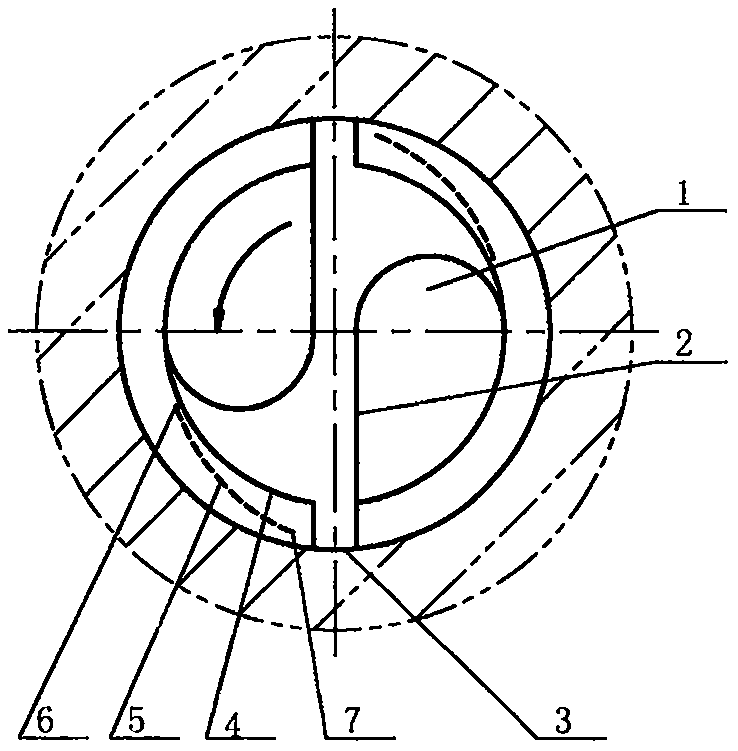

Self-centering anti-deviation vibration reduction hole machining tool

A technology for machining tools and vibration-damping holes, which is applied in the directions of manufacturing tools, metal processing equipment, drilling tool accessories, etc. Low, simple scheme, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] Implementation method: wedge-shaped contour line is used for twist drill or reaming drill; wedge-shaped contour line is used for straight shank drill bit or taper shank drill bit; wedge-shaped contour line is used for manual oiling or oil pump supply; wedge-shaped contour line is used for cover Or without cover processing; wedge-shaped contour line is used in the case of tool rotation or workpiece rotation. Wedge contours are used for center drills, flat drills, boring cutters, and reamers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com