Biomass energy particle forming method

A technology of biomass energy and particles, which is applied in the direction of biofuel, raw material extrusion granulation, waste fuel, etc., can solve the problems of unfavorable unified collection and storage, different particle sizes and shapes, and small pieces of different shapes and sizes, and achieve convenience The effects of collection and transportation, uniform particle quality, and uniform size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

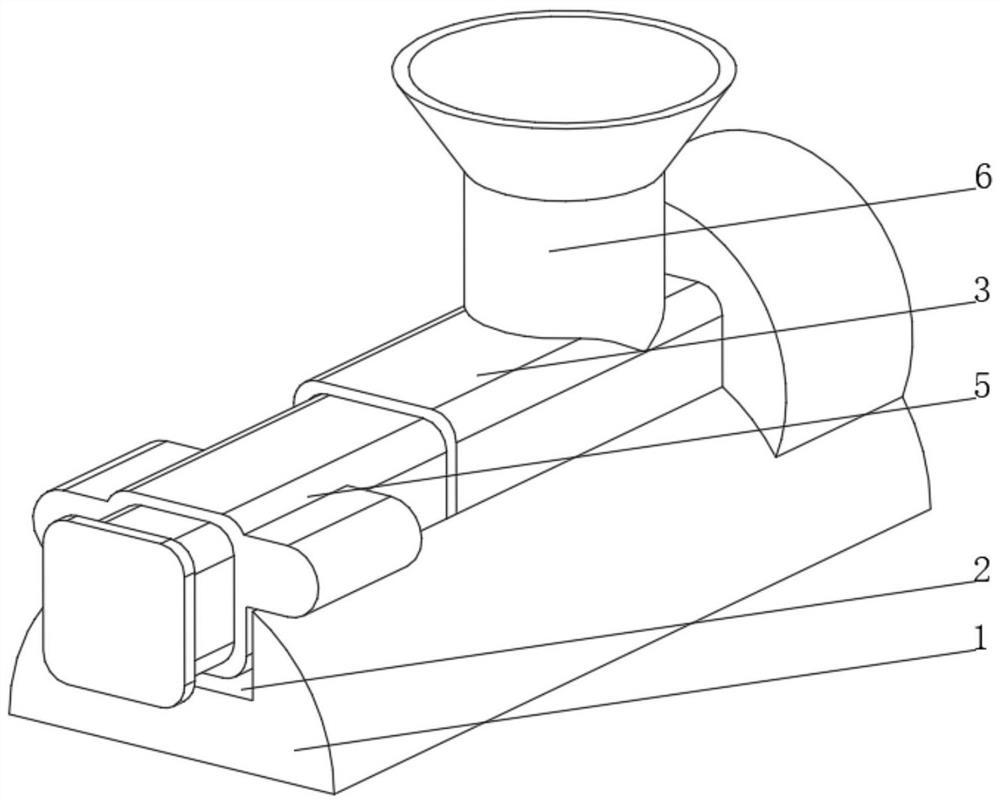

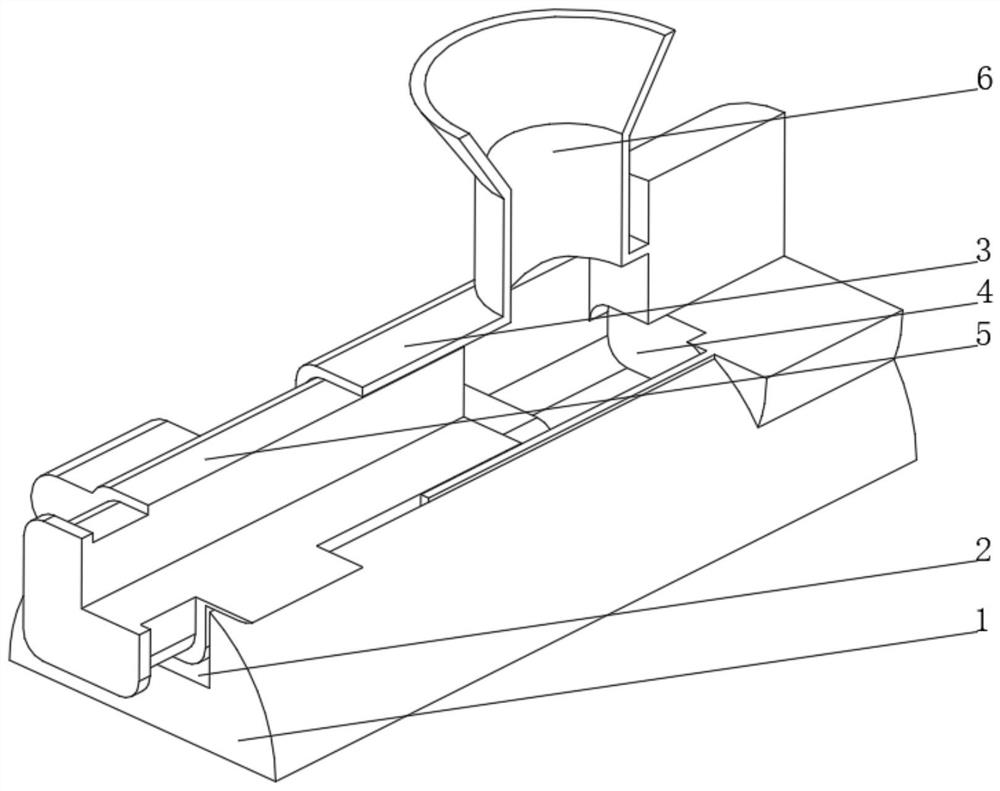

[0039] See Figure 1-5 The present invention provides a technical solution: a molding apparatus for biomass particles, specific comprising:

[0040] Fixed base 1, the top of the fixed base 1 is opened, the inner wall of the slide 2 is fixedly connected to the shaped cartridge 3, and the shaped tank 3 is opened at one end of the shaped cartridge 4;

[0041] The extrusion device 5 is disposed inside the shaped cartridge 3 and is slidably connected to the inner wall of the shaped groove 3;

[0042] The feed port 6 is disposed at the top of the shaped cartridge 3 and inner communication with the molded cartridge 3, and the feed port 6 is disposed at the top of the shaped cartridge 3 located between the extruded device 5 and the shaped groove 4;

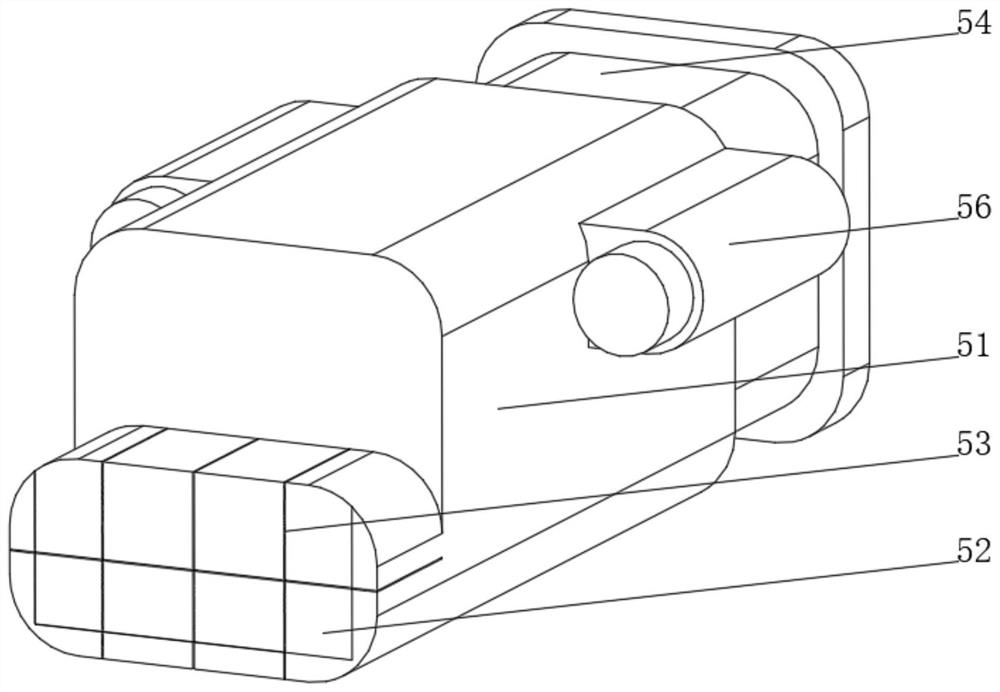

[0043] The extrusion device 5 includes:

[0044] The extruded housing 51 is provided with an extruded head 52 that is adapted to the shaped groove 4, and the cutting tank 53 is opened on the extruded head 52;

[0045] The cut slider 54 is disp...

Embodiment 2

[0054] According to the molding apparatus of the above biomass energy particles, a molding method of biomass energy particles is proposed, including the following steps:

[0055] S1, the raw material is input to the inside of the molded cylinder by the feed port, and the raw material inside the molded cylinder includes a raw material pile in the molded cartridge, and then pushes the extrusion device through the external hydraulic device, and the extrusion device slides toward the direction of the shaped groove and pushes. Stacked materials inside the molded tube;

[0056] S2, the raw material pile is pushed toward the shaped tank, and the feedstock is pushed to the inside of the molded slot by the extruded head, and the raw material is extruded by the inner wall of the extruded head and the molded groove;

[0057] S3, continuously push the cutting slipper, the cutting slider drives the sliding electromagnet through the fixing plate, since the sliding electromagnet is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com