Steamed bun forming machine

A technology for forming machine and steamed buns, which is applied to dough forming machinery or equipment, dough extruders, baking, etc., can solve the problems of uncertainty, inconvenience in making steamed buns, irregular shape of round buns, etc., and achieve uniform size and shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

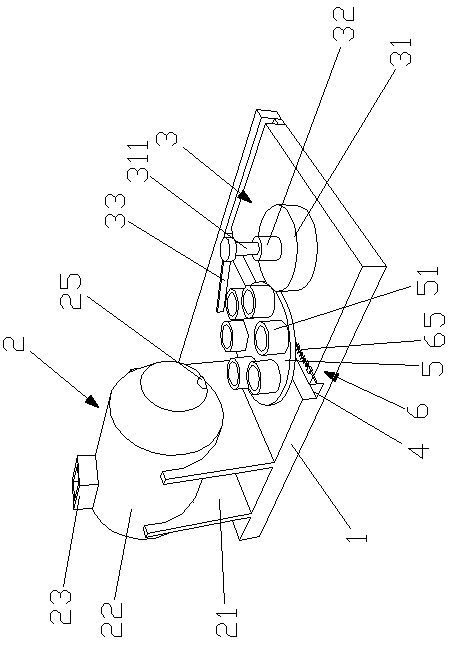

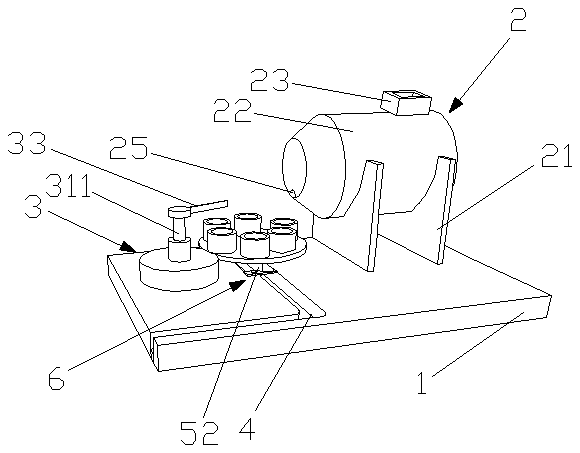

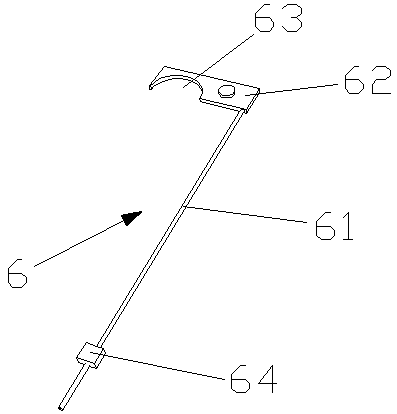

[0022] Such as Figure 1-4 As shown, a steamed bun forming machine of the present invention includes a forming machine 1, and the two ends of the forming machine 1 are respectively provided with a discharge device 2 and a material shifting control device 3, and the discharge device 2 includes a discharge barrel frame 21, The discharge barrel frame 21 is fixedly provided with a discharge barrel 22, the top of the discharge barrel 22 is provided with a feed port 23, the inside of the discharge barrel 22 is provided with a screw shaft 24, and the side wall of the discharge barrel 22 is also provided with a There is a discharge port 25, the screw shaft 24 is horizontally arranged in the discharge barrel 22, the material shifting control device 3 includes a turntable 31 and a motor 32, the motor 32 is arranged on the molding machine 1, and the turntable 31 is arranged on the output shaft of the motor 32 , the turntable 31 is also provided with a shift rod 33, and the forming machin...

Embodiment 2

[0024] Both ends of the molding machine 1 are respectively provided with a discharge device 2 and a material shifting control device 3, the discharge device 2 includes a discharge barrel frame 21, and a discharge barrel 22 is fixedly arranged on the discharge barrel frame 21, and the discharge barrel 22 The top of the tank is provided with a feed port 23, the inside of the discharge barrel 22 is provided with a screw shaft 24, and the side wall of the discharge barrel 22 is also provided with a discharge port 25, and the screw shaft 24 is horizontally arranged in the discharge barrel 22, The material shifting control device 3 includes a turntable 31 and a motor 32, the motor 32 is arranged on the molding machine 1, the turntable 31 is arranged on the output shaft of the motor 32, and the turntable 31 is also provided with a shifting lever 33, the discharge bucket frame 21 and An L-shaped track 4 is also arranged on the forming machine 1 between the material shifting control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com