Filtering device for greenhouse gas emission

A filtration device and technology for greenhouse gases, which are applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to filter greenhouse gases, inconvenient disassembly and replacement, etc., and achieve good heat insulation effect and improve filtration effect. , good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

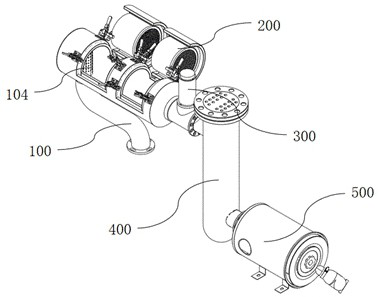

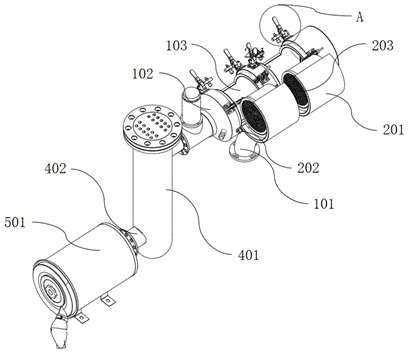

[0030] refer to Figure 1~Figure 6 , a filter device for greenhouse gas emissions is proposed in this embodiment, comprising:

[0031] Pipe mechanism 100: including combustion pipe 102, which is a circular steel tank body, and an air intake pipe 101 is installed on one side of combustion pipe 102;

[0032] Purification mechanism 200: it is installed on the outside of the combustion tube 102, including a connecting buckle 202 that drives the rotation of the flip door 201 and a quick replacement component, and a filter element 203 is installed on one side of the two flip doors 201;

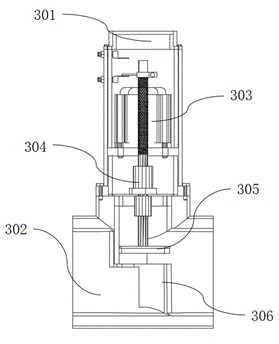

[0033] Valve mechanism 300: including a connecting pipe 302 connected to the combustion pipe 102 and an electric control assembly;

[0034] Heat dissipation mechanism 400: includes a heat dissipation pipe 401 and an interface 402, which is connected to the connecting pipe 302 through the interface 402, the two interfaces 402 are installed on both sides of the heat dissipation pipe 401, and a heat d...

Embodiment 2

[0047] The exhaust pipe is connected to the intake pipe 101. When the exhaust gas is not discharged, the cylinder 303 drives the air-tight plug 305 to close, and the connecting pipe 302 is blocked. The exhaust gas continues to accumulate in the combustion pipe 102, increasing the internal pressure and temperature of the combustion pipe 102. The exhaust gas contacts the filter element 203, Since the catalyst in the filter element 203 needs to reach a higher reaction rate under a certain temperature and pressure, the temperature sensor and the pressure sensor monitor the internal conditions of the combustion tube 102 in real time, and the temperature and pressure are controlled within a certain range. When the temperature is high, the cylinder 303 starts to open the air-blocking plug 305, and the exhaust gas is discharged to prevent the device from being damaged due to excessive internal pressure and reduce the filtering effect when the pressure is low. When the temperature and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com