Two-way clutch

A technology of two-way clutches and engaging parts, which is applied to one-way clutches, clutches, mechanical equipment, etc., can solve the problems of axial enlargement of two-way clutches, and achieve the effect of compact axial size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

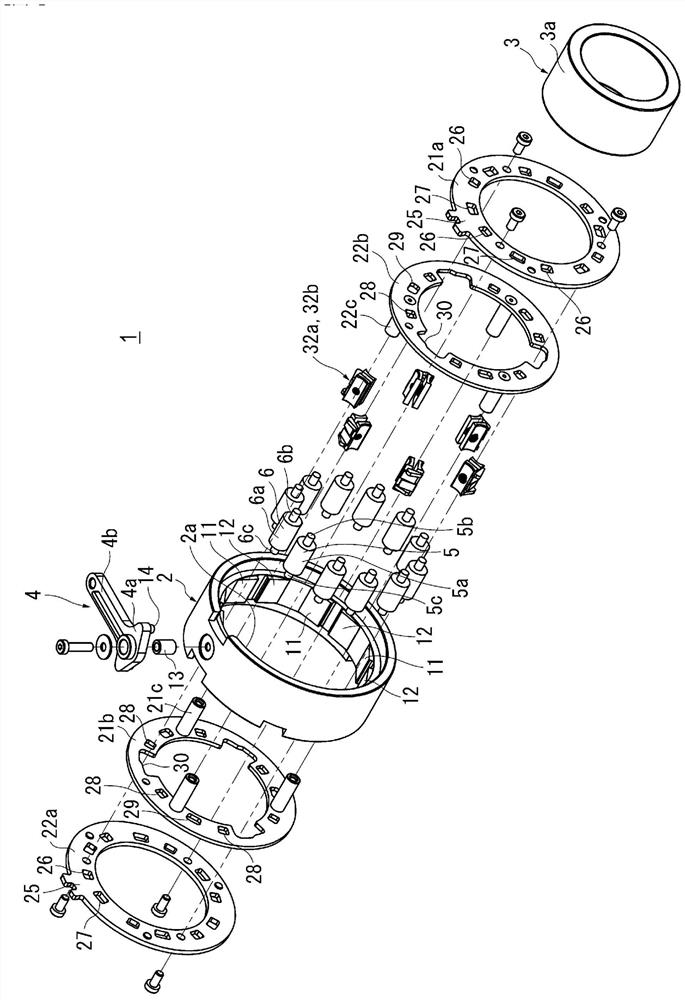

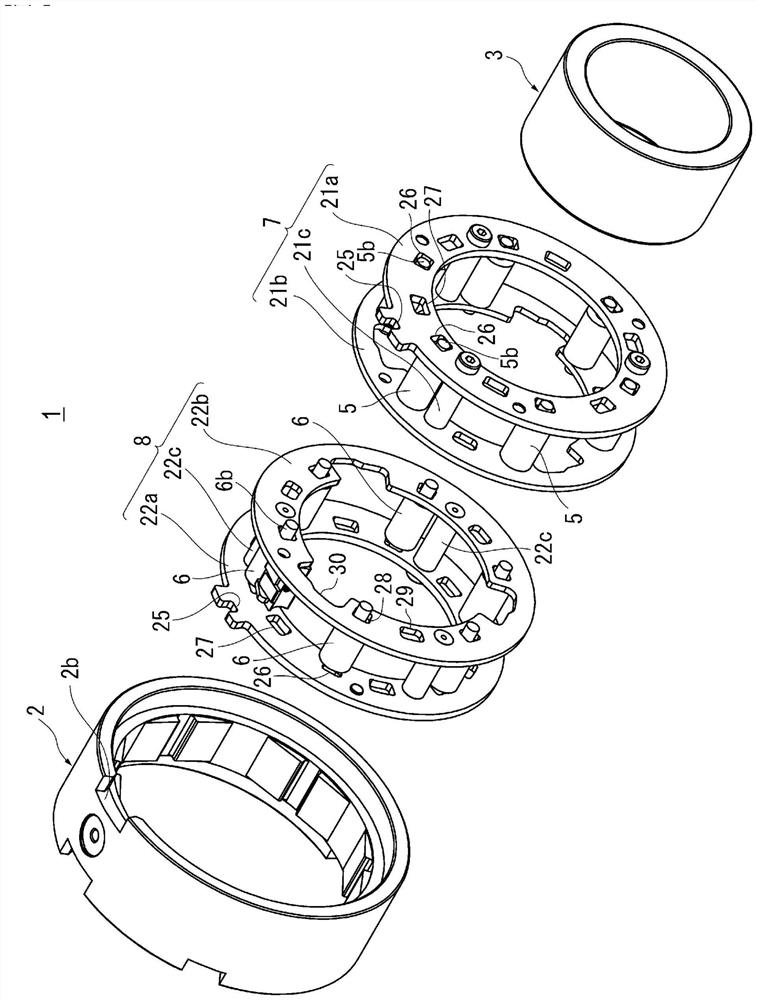

[0026] The two-way clutch according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings. However, the two-way clutch of the present invention can be realized in various forms, and is not limited to the embodiments described in this specification. The present embodiment is provided only for the purpose of enabling those skilled in the art to fully understand the scope of the invention by sufficiently disclosing the specification.

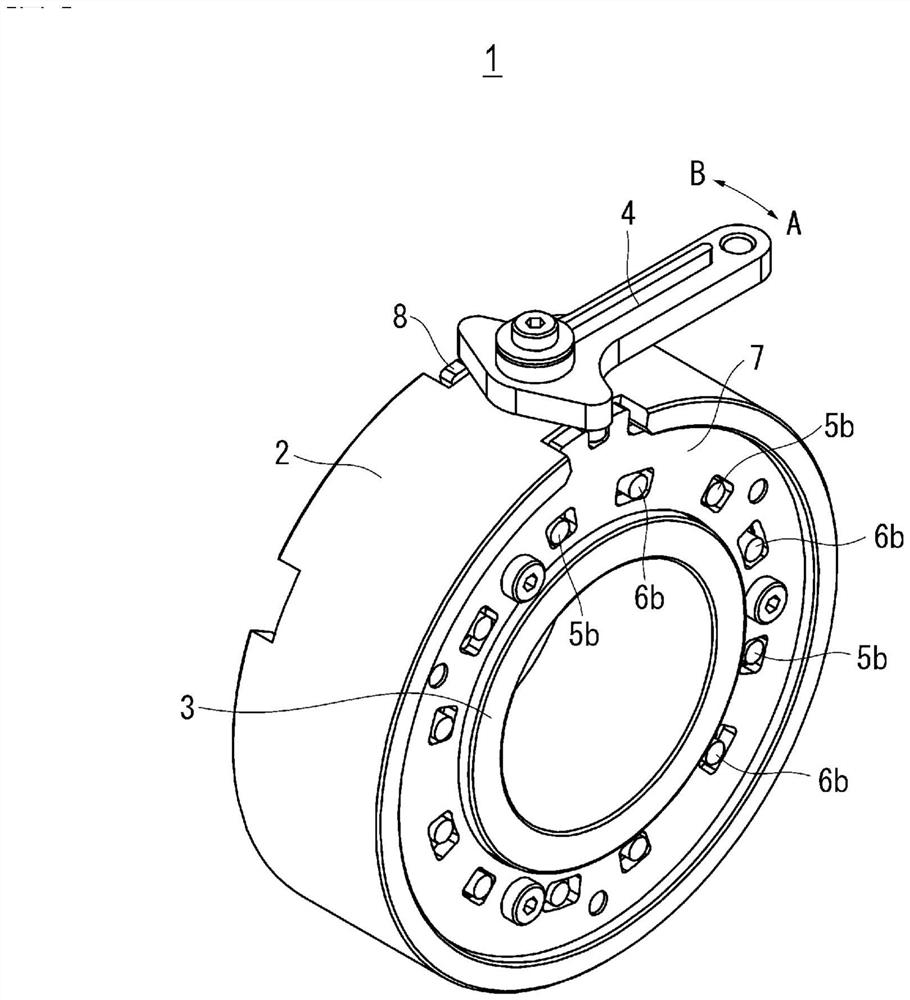

[0027] figure 1 An external perspective view of a two-way clutch according to an embodiment of the present invention is given. The two-way clutch 1 of the present embodiment includes an outer ring 2 as an outer member, an inner ring 3 as an inner member, and a group of first rollers 5 ( figure 1 Shaft 5b) of the first roller 5 group, the second roller 6 group ( figure 1 The shaft 6b) of the second roller group 6, the first cage 7, the second cage 8, and the shank 4 are shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com