Flywheel energy storage system and control method thereof

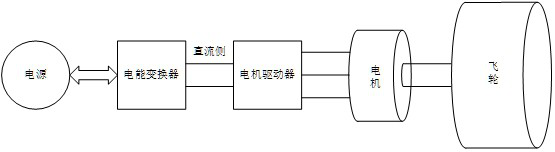

A flywheel energy storage and control method technology, which is applied in the field of flywheel energy storage system and its control, can solve the problems of low system efficiency, large loss, high cost, etc., and achieve the effects of improving overall efficiency, reducing loss, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

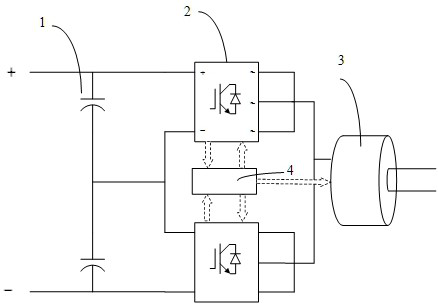

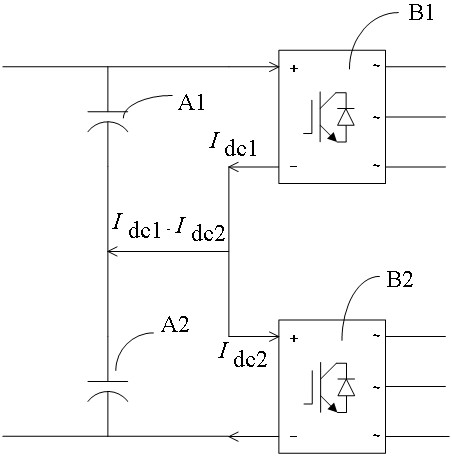

[0037] figure 2 A schematic structural diagram of a flywheel energy storage system provided in an embodiment of the present invention, such as figure 2 As shown, the system includes: a capacitor bank, at least two three-phase inverter bridges 2 , at least one motor 3 and a control unit 4 . The connection relationship between the above modules is as follows: the capacitor bank is connected to the high-voltage power supply, all capacitors 1 in the capacitor bank are connected in series in sequence, the number of capacitors 1 is consistent with the number of three-phase inverter bridges 2, and the positive pole of each capacitor 1 is It is connected with the positive pole of the DC side of the corresponding three-phase inverter bridge 2, the negative pole of each capacitor 1 is connected with the negative pole of the DC side of the corresponding three-phase inverter bridge 2, and the AC side of the three-phase inverter bridge 2 is connected with the motor 3 One end is connecte...

Embodiment 2

[0070] According to an embodiment of the present invention, an embodiment of a control method for a flywheel energy storage system is provided. It should be noted that the steps shown in the flow charts of the drawings can be executed in a computer system such as a set of computer-executable instructions , and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0071] Figure 9 A flow chart of a control method for a flywheel energy storage system provided by an embodiment of the present invention is applied to the control unit in the flywheel energy storage system as described in Embodiment 1, such as Figure 9 As shown, the method includes the following steps:

[0072] Step S101, obtaining the actual voltages of all capacitors and the AC side currents of all three-phase inverter bridges;

[0073] Step S102 , in the charging stage of the flywheel energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com