Connector

A connector and conductive connection technology, applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve the problems of easy piercing of the internal parts of the box, and reduce the pressure, width, size, etc. The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

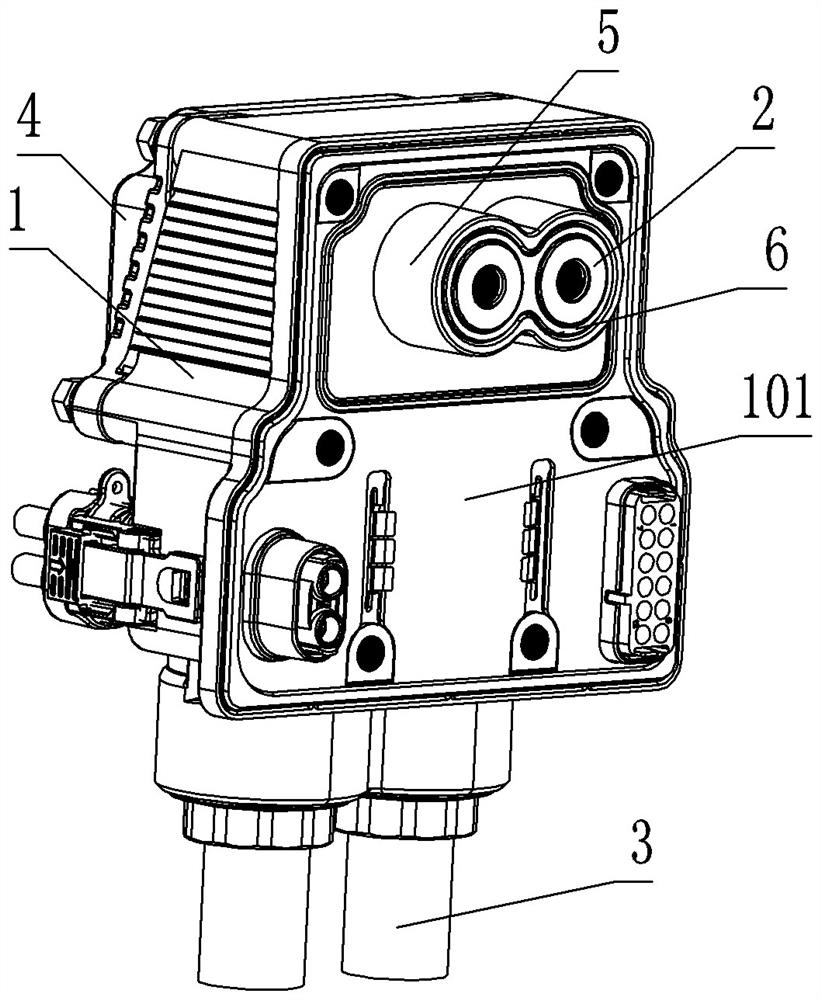

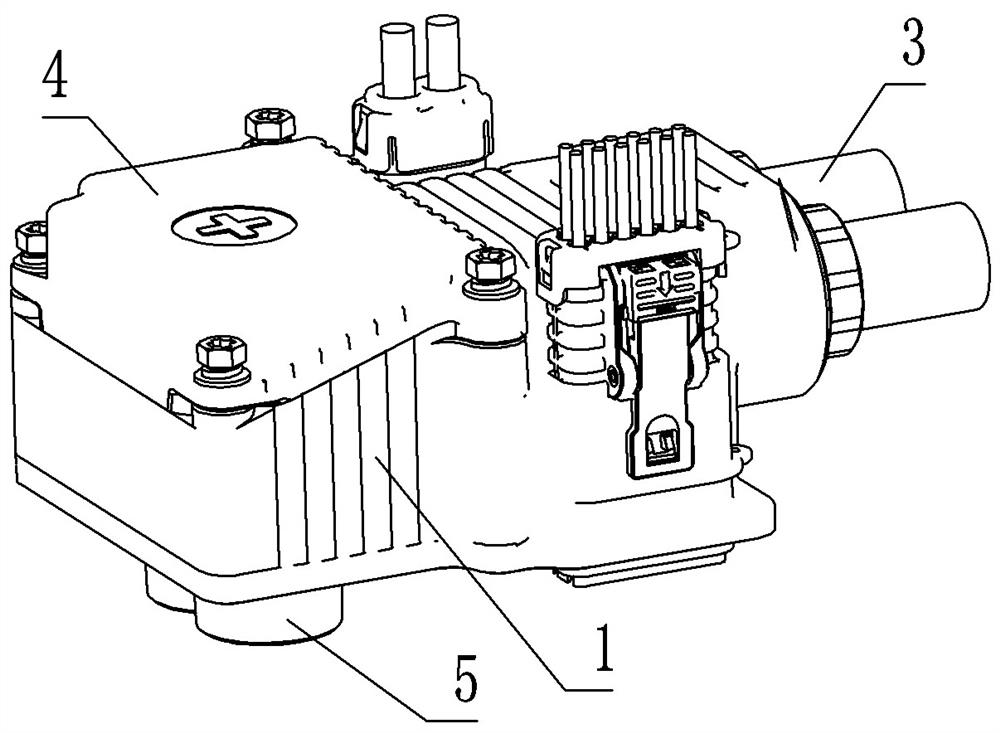

[0050] Such as figure 1 and figure 2 As shown, the connector includes a housing 1, and a conductive member is provided in the housing 1. The conductive member in this embodiment is a conductive post 2, and the conductive post 2 is used for conductive connection with the wire 3 in the housing 1.

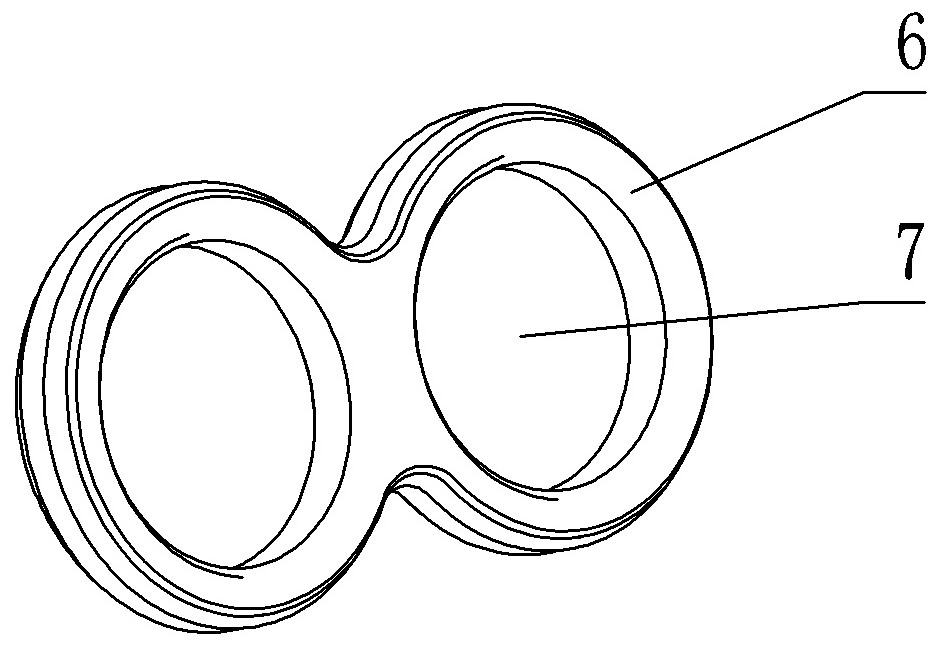

[0051] The connector in this embodiment is connected with two wires 3 , and the arrangement of the two wires 3 can prevent the single wire from being too large in diameter and inconvenient to be bent, thereby inconvenient for installation and wiring. There are two conductive columns 2 that cooperate with the two wires 3 to form a conductive connection, and the two conductive columns 2 are arranged side by side and spaced apart.

[0052] The housing 1 has an installation side 101, which is used to be fixed and press-fitted on the box wall of the corresponding box, so that the connector is fixedly connected with the corresponding box.

[0053] In order to describe this embodiment mor...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is that the connector in Embodiment 1 is connected with two wires, and two corresponding conductive columns are provided to realize conductive connection with the two wires respectively, while in this embodiment , the connector is only provided with one wire, and the corresponding conductive post is provided with one, so as to realize the conductive connection.

Embodiment 3

[0077] The difference between this embodiment and Embodiment 1 is that the conductive column in Embodiment 1 includes an inner cylinder and an outer cylinder, and the inner cylinder and the outer cylinder are respectively used for connecting wires and external conductive bars, while in this embodiment Among them, the conductive column is an integral cylinder, and the two ends of the conductive column are respectively used to connect the wire and the external conductive bar. Correspondingly, the external conductive bar has a wider section, and the wider section of the external conductive bar is provided with Holes for bolts for fitting connection with conductive posts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com