Steel wire damage detection experiment platform based on magnetic memory signal

A damage detection and experimental platform technology, applied in the direction of material magnetic variables, etc., can solve the problem of not being able to strictly control the moving speed of the sensor and the distance between the sensor and the steel wire, and achieve the effect of achieving integrity and rigor and reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

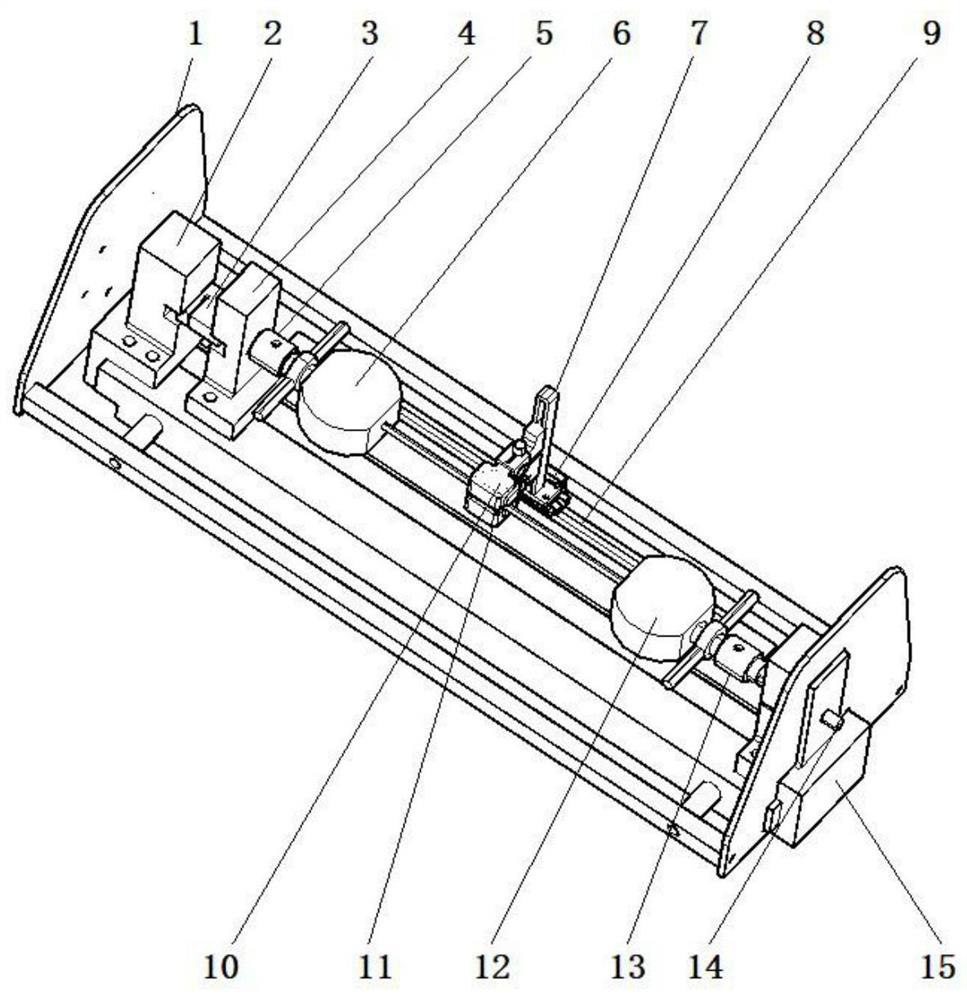

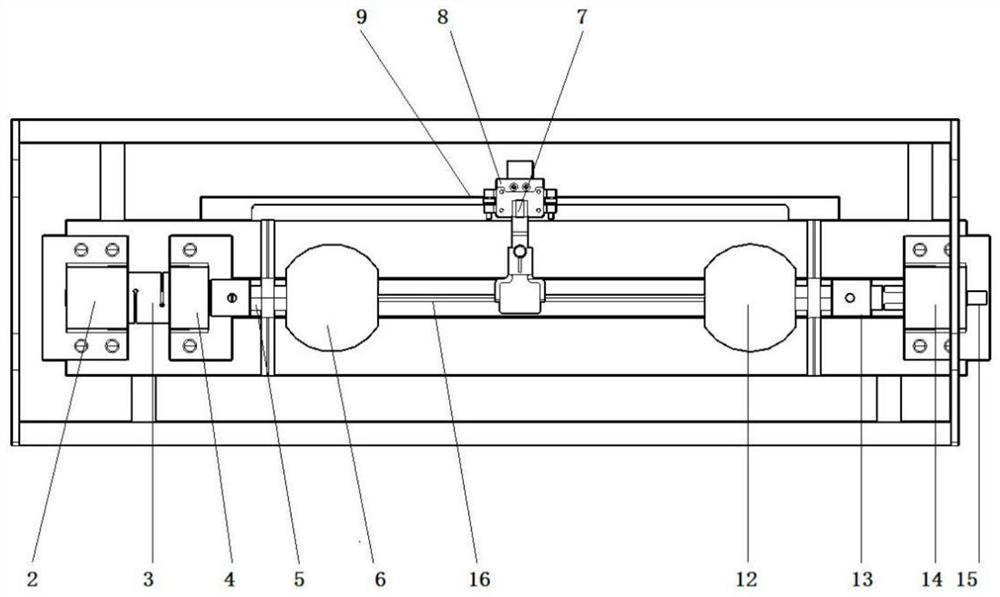

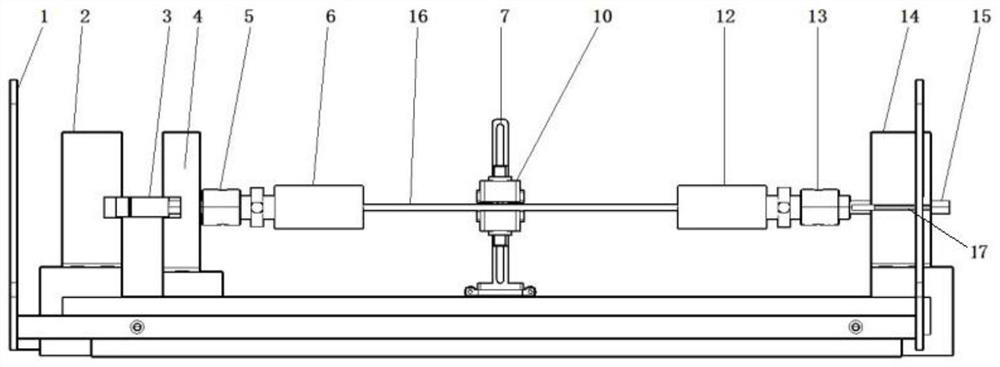

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0023] In this example, see Figure 1-Figure 3 As shown, the present invention proposes a steel wire damage detection experimental platform based on magnetic memory signals, including a support frame 1, a tension sensing component, a left tensile clamp 6 component, a sliding magnetic memory sensing probe component, and a right tensile clamp 12 Components and tension applying components, the tension sensing component, the left stretching fixture 6 component, the sliding magnetic memory sensing probe component, the right stretching fixture 12 component and the tension applying component are arranged sequentially on the support frame 1;

[0024] The tension sensor assembly is connected to the left tension fixture 6 assembly, the right tension fixture 12 assembly is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com