Wide-flange heavy hot-rolled H-shaped steel, and production method and application thereof

A production method and technology for H-beams, applied in the field of rolling steel production, can solve the problem that the width of the flange cannot meet the requirements of the supporting structure of the foundation pit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

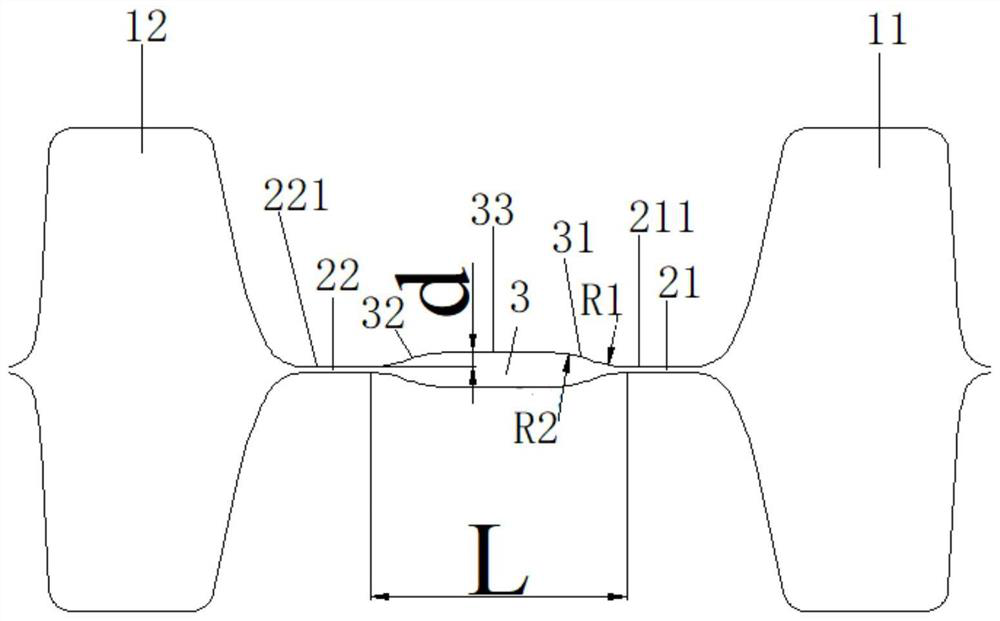

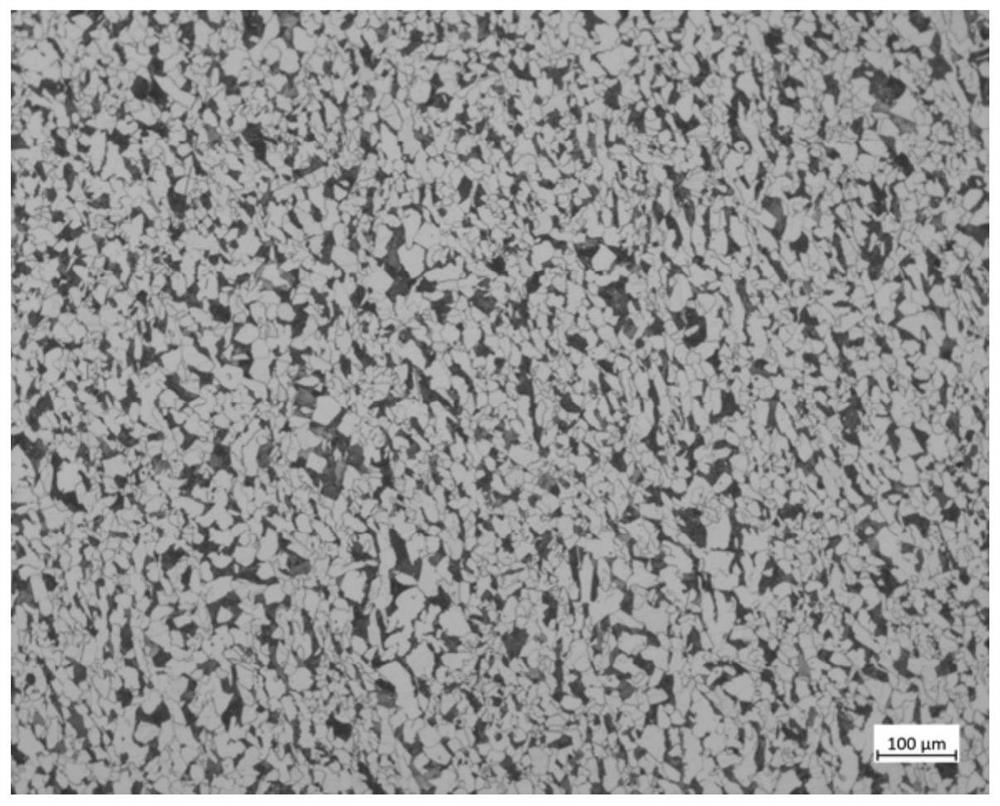

[0067] The rolling specifications in this example are H500×500 series specifications, the thickness of the flange is 130mm, and the components of the steel are: C: 0.12%, Si: 0.41%, Mn: 1.45%, P: 0.011%, S: 0.007%; V: 0.04%, Nb: 0.040%, H: 0.00010%, N: 0.005%, Alt: 0.012%, and the rest are Fe and trace residual elements. Adopt production technique of the present invention to produce, wherein process parameter control is as follows:

[0068] A. Blank heating: heating temperature 1250°C, time in furnace 40min;

[0069] B. Descaling: when descaling, the running speed of the rolled piece is 1.6m / s, and the descaling water pressure is 17MPa;

[0070] C. Billet rolling: The billet is roughly rolled by a two-roller reversible billet mill. The billet is first rolled in two passes in a box-shaped pass to reduce the height of the billet. The height is 740mm and the inner width is 340mm. The temperature is 1200°C, the final rolling temperature is 1070°C, and the rolling reduction ratio...

Embodiment 2

[0077] The specification of this embodiment and the composition of steel are identical with embodiment 1. The post-rolling controlled cooling process selects the post-rolling quenching self-tempering process, and its self-tempering temperature is 600 ° C. The remaining production process control parameters are the same as in Example 1. The mechanical properties are tested. The yield strength is 436MPa, and the tensile strength is 621MPa, the yield ratio is 0.70, the elongation after fracture is 22%, and the impact energy KV2 at 0°C is 56J. The flange width in the cross-sectional dimension of the finished product is 510mm.

Embodiment 3

[0079] The specification of this embodiment is H600×500 series, the thickness of the flange is 90mm; the steel components are: C: 0.13%, Si: 0.41%, Mn: 1.45%, P: 0.012%, S: 0.008%, V: 0.041%, Nb: 0.039%, H: 0.00013%, N: 0.004%, Alt: 0.013%, and the rest is Fe and trace residual elements. Adopt production technology of the present invention to produce, wherein rolling process parameter control is as follows:

[0080] A. Billet heating: The billet is a special-shaped billet, the heating temperature in the heating furnace is 1240 ° C, and the time in the furnace is 38 minutes;

[0081] B. Descaling: when descaling, the running speed of the rolled piece is 1.4m / s, and the descaling water pressure is 16MPa;

[0082] C. Billet rolling: The billet is roughly rolled by a two-roller reversible billet mill. The billet is first rolled in two passes in a box-shaped pass to reduce the height of the billet. The height is 835mm and the inner width is 435mm. The temperature is 1200°C, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flange thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com